Construction method and equipment of holding and pressing type static-pressure driven cast-in-place pile

A technique of sinking tubular piles and static pressure, applied in the direction of sheet pile walls, foundation structure engineering, building construction, etc., can solve the problem of large vibration force, noise and oil smoke pollution, damage to the soil structure of the pile body, and affect adjacent buildings Object safety and surrounding ecological environment and other issues, to achieve the effect of shortening auxiliary working hours, flexible movement, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention is further described as follows in conjunction with specific embodiment:

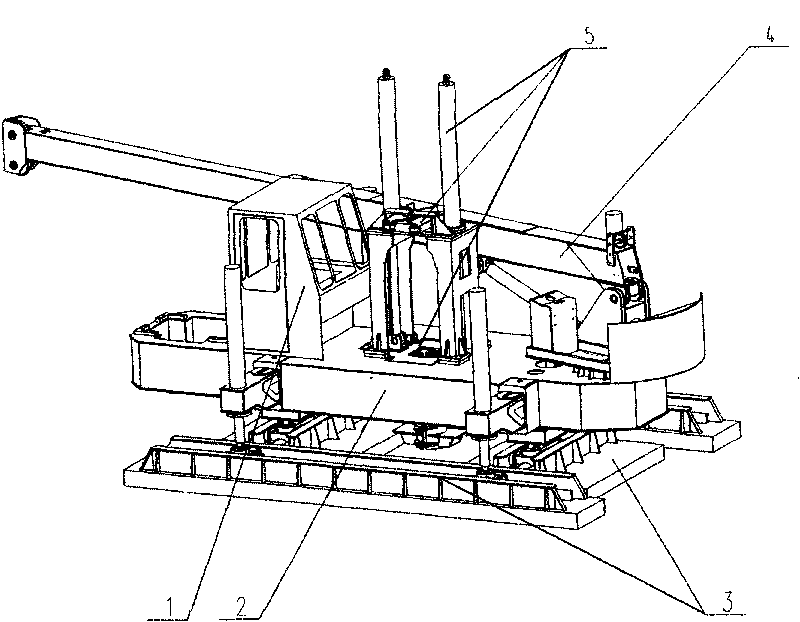

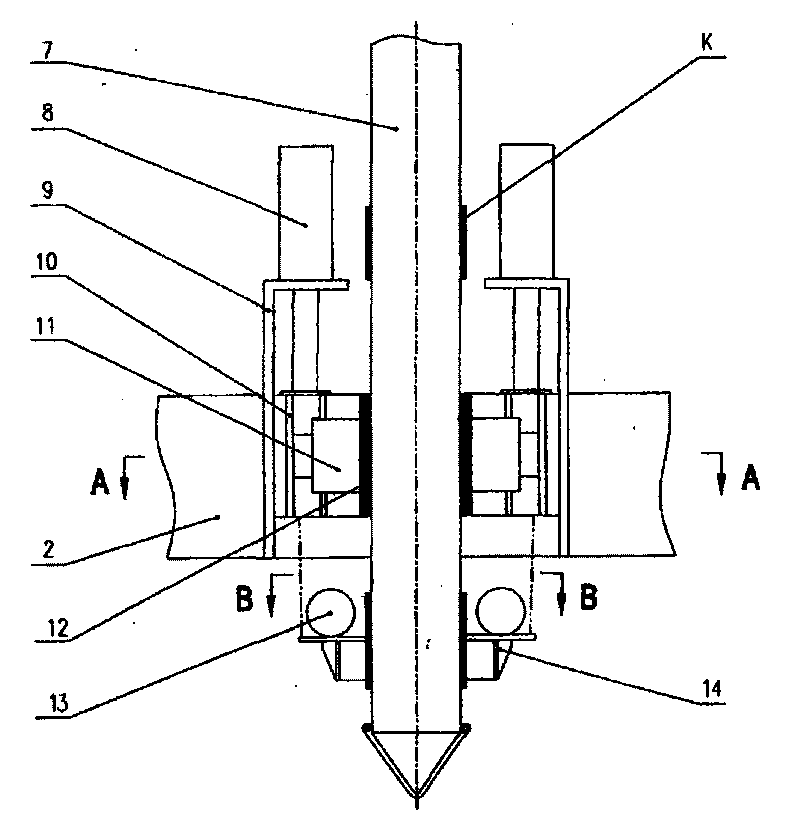

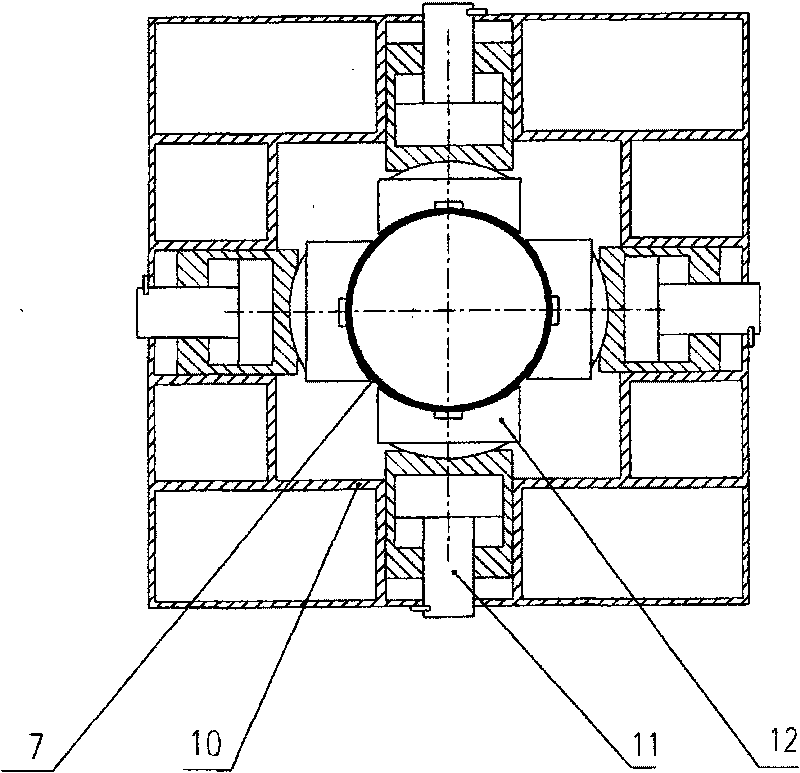

[0019] A construction method of pressure-holding static pressure pipe-sinking pile. The equipment used in the method is a pressure-holding static pressure pipe-sinking pile machine. For its overall structure, see the attached figure 1 , mainly including the operating device 1, the fuselage 2, the running mechanism 3, the pile hanging mechanism 4, and the pile clamping and pile pressing mechanism 5, the pile clamping and pile pressing mechanism 5 is a side-hugging pile clamping and pile pressing mechanism, see the attached figure 2 , it is vertically fixed on the fuselage 2 by the pile-pressing frame 9, and the inside of the pile-pressing frame 9 has a vertical slide rail, and the slide rail is equipped with a pile clamping box 10 that slides up and down along the slide rail, and the pile-pressing frame 9 passes through the pile-pressing oil cylinder. 8 is connected with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com