Method for processing cutter blank of kitchen knife

A processing method and a technology of knife blanks, which are applied in the field of kitchen knife blank processing, can solve the problems of slow processing speed, uneven forging, and high scrapping of knife blanks, so as to improve quality and mechanical properties, improve processing quality, and reduce labor costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

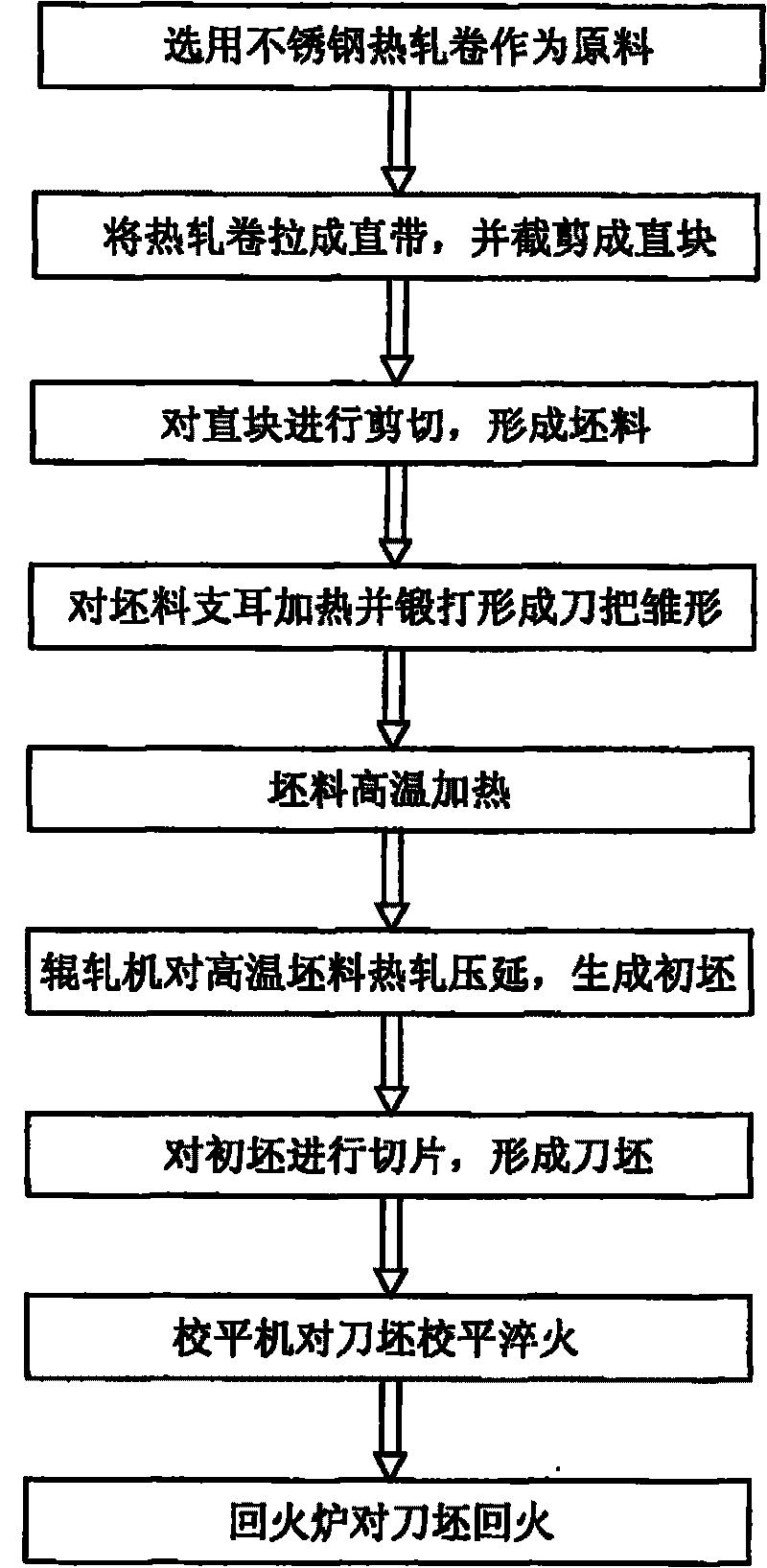

[0031] Below in conjunction with accompanying drawing and embodiment the present invention will be further described: take the processing method of two kitchen knife blanks as example:

[0032] like figure 1 Shown, a kind of processing method of kitchen knife blank is made up of following steps;

[0033] Step 1. Select martensitic stainless steel hot-rolled coil as raw material;

[0034] Step 2. Pull the hot-rolled coil into a straight strip with a straightening machine, and use a shearing machine to transversely cut the straight strip, and cut it into a straight block;

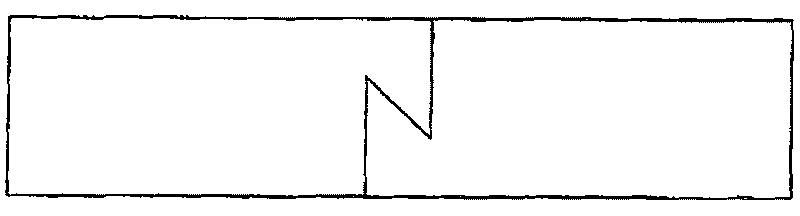

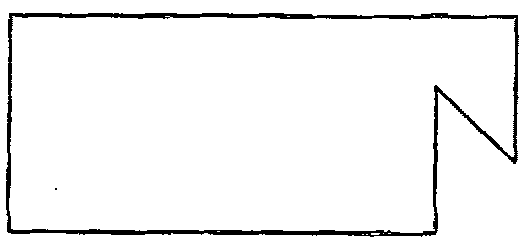

[0035] Step 3: Use the shearing machine to cut the middle part of the straight block, and punch a straight block into two blanks with the same shape. The mold of the punching machine is "N" shape, and the blank is one end with a Rectangular steel plates for the lugs, the two cut pieces left after stamping by the "N"-shaped punch are respectively connected to the two rectangular steel plates as lugs;

[003...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com