Lamp tube type LED lamp

An LED lamp, lamp tube type technology, applied in the direction of lampshade, cooling/heating device of lighting device, lighting and heating equipment, etc., can solve the problems of small illumination range, poor light output rate, high production cost, etc. range, reduced production costs, and improved thermal performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

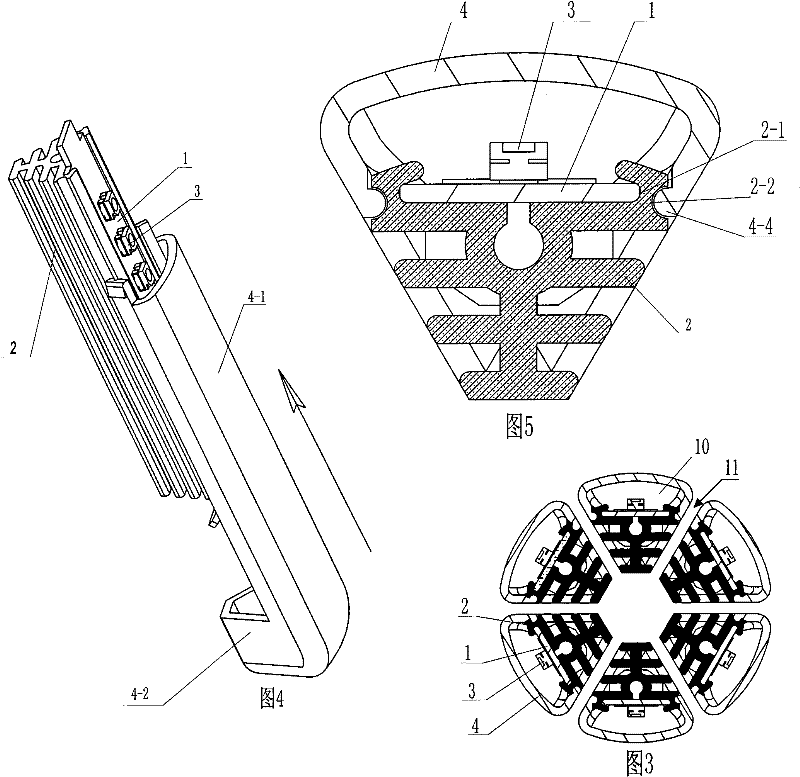

[0029] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings of the description.

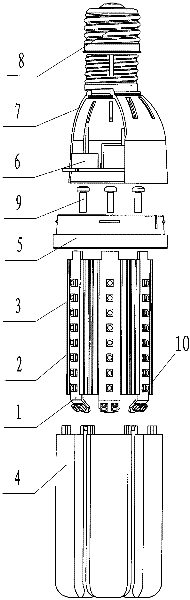

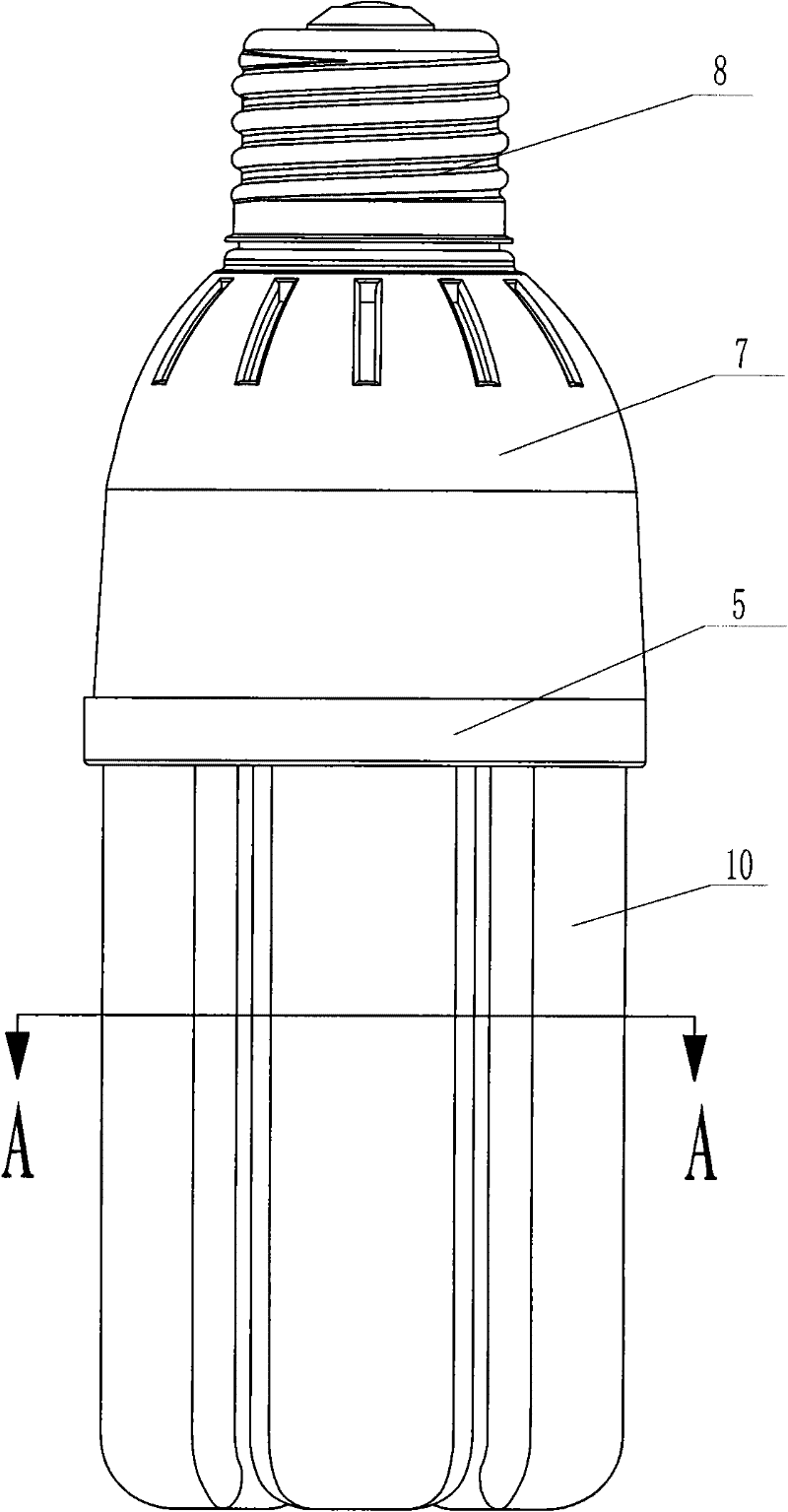

[0030] Such as figure 1 , figure 2 As shown, the tube-type LED lamp includes a lampshade 4, a lamp holder 5 and a group of LED lamps 3 arranged on the lamp holder. The lamp holder is arranged at the lower end of the lamp holder shell 7, the lamp holder housing is provided with a power rectifier 6, and the top of the lamp holder housing is provided with a screw cap 8 screwed with an external power supply; the above is the conventional structure of the LED lamp.

[0031] In the present invention, six LED units 10 (such as image 3 As shown), adjacent LED units are separated by a certain distance to form air convection grooves 11 that are conducive to heat dissipation; by setting air convection channels (that is, air convection grooves) between adjacent LED lamp units, the performance of LED lamps is improved. The heat diss...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com