Rectangular microstrip patch antenna

A microstrip patch antenna and rectangular technology, applied in the direction of antennas, electrical components, etc., can solve the problems of antenna performance degradation, increase in antenna size, volume or processing complexity, and can not meet the requirements of wireless communication technology, so as to achieve low processing cost, Suppression of backward radiation and easy processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

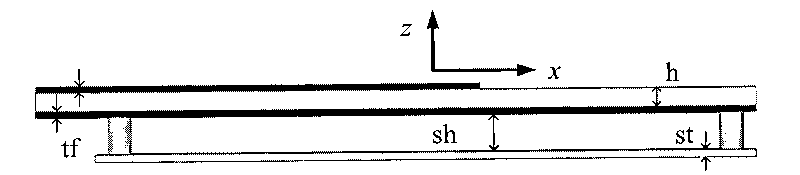

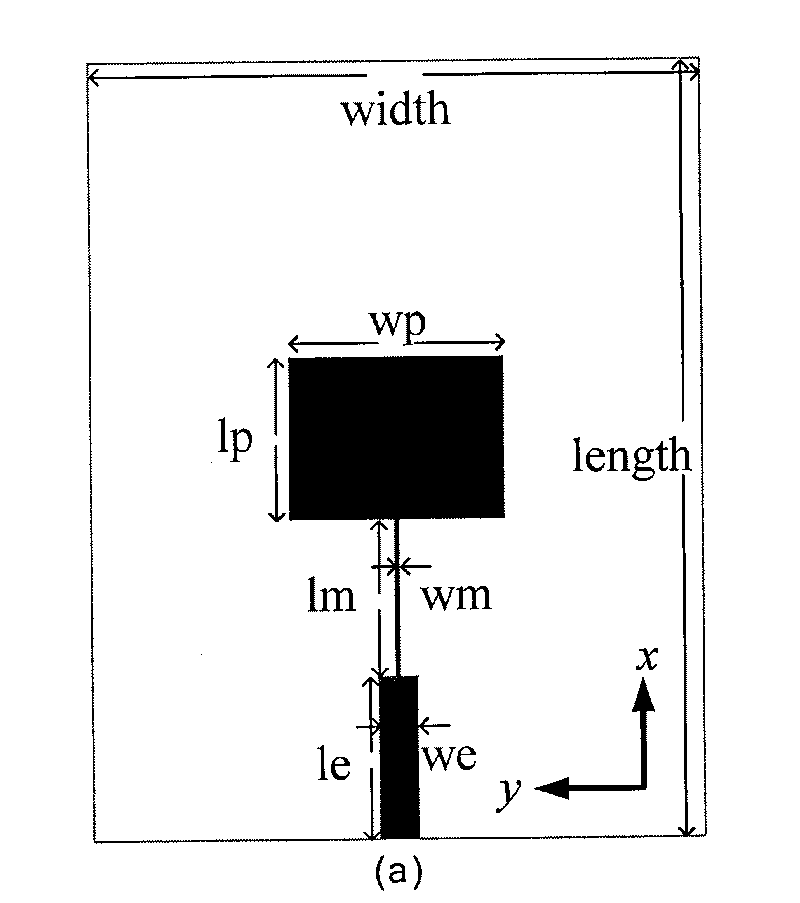

[0024] The present invention includes an upper patch layer, a lower metal floor and a dielectric substrate between the two. Specific patterns are etched on the metal floor, and the entire etching area is located directly below the radiation patch of the upper patch layer. Corresponding to the area, the etching pattern is formed by periodic arrangement of basic planar units in two orthogonal directions in the metal floor, and the basic unit is an embedded curved line structure.

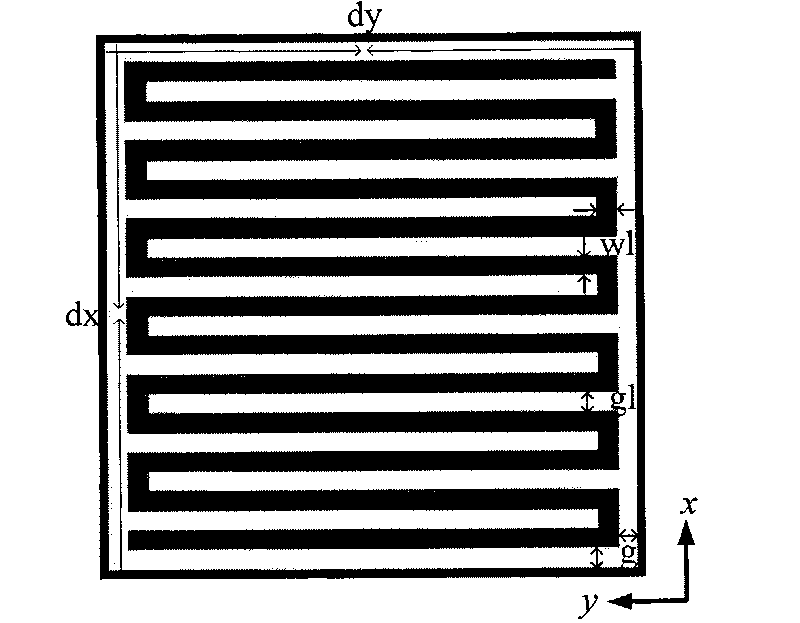

[0025] The periodically arranged embedded curved line structure etched on the metal floor is etched on the copper layer of the copper-clad dielectric substrate by ordinary PCB technology. The embedded curved line structure is an inlaid metal curved line in the rectangular etched area, such as figure 1 , the etching pattern is periodically arranged in two orthogonal directions x and y in the metal floor. The black area in the figure is copper, and the white area represents that the copper in the correspo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com