Crude stalk chopper capable of automatically adjusting feeding height

An automatic adjustment and shredding device technology, applied in cutting equipment, agricultural machinery and implements, applications, etc., can solve the problems of lack of shredding equipment, particle size that cannot meet biomass compression molding, increase production costs, etc. Crushing performance, improve throwing performance, increase the effect of uneven running

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

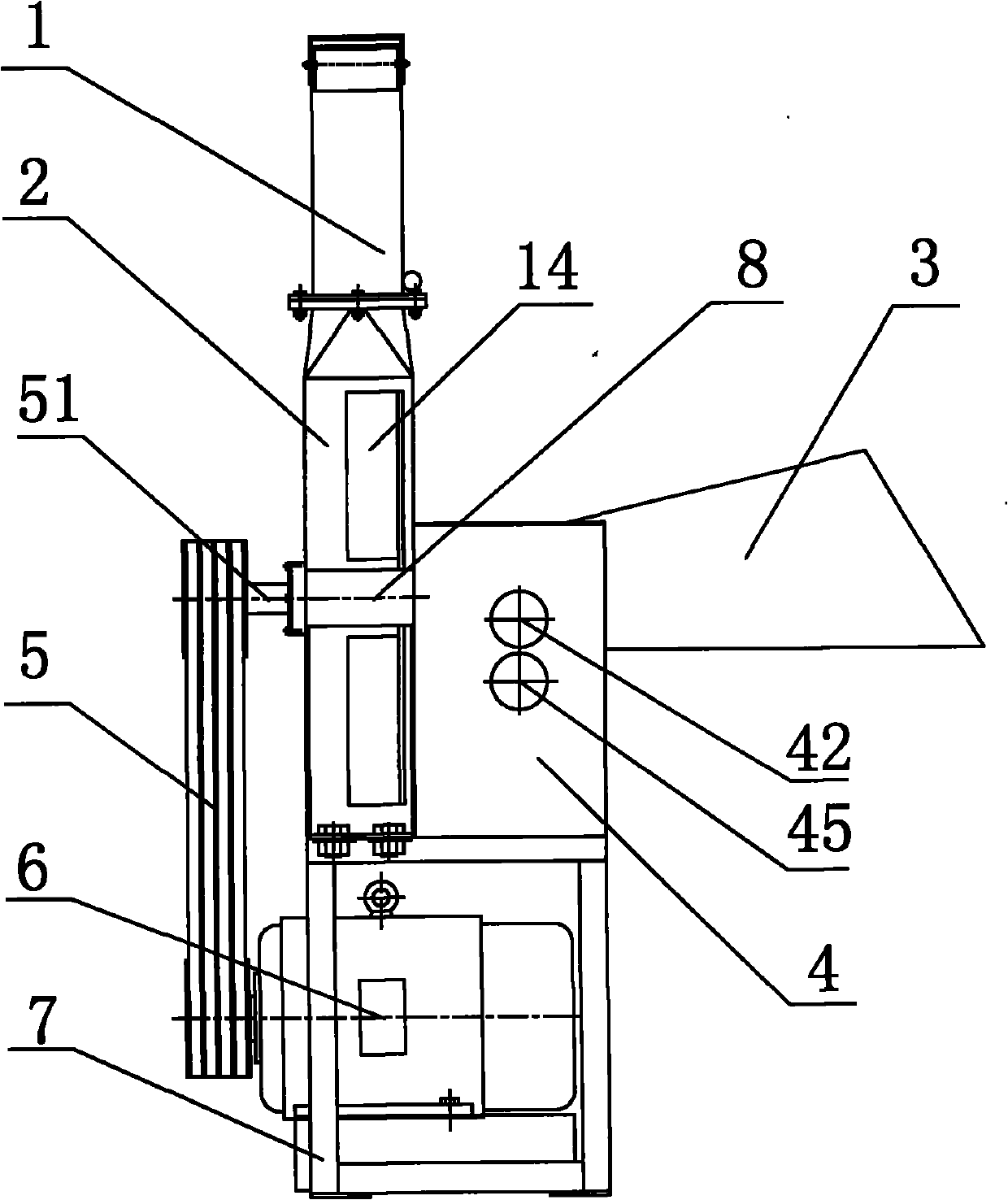

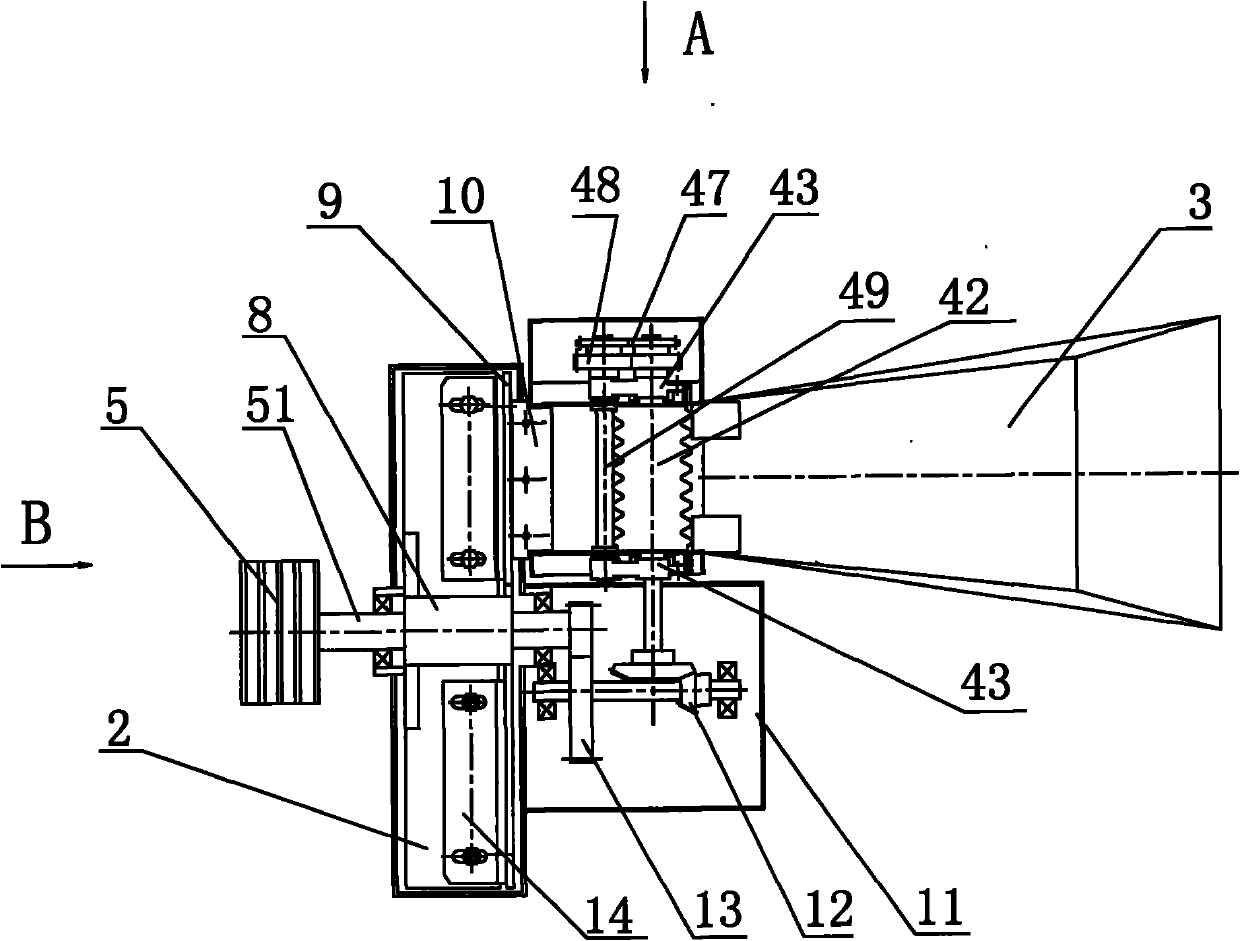

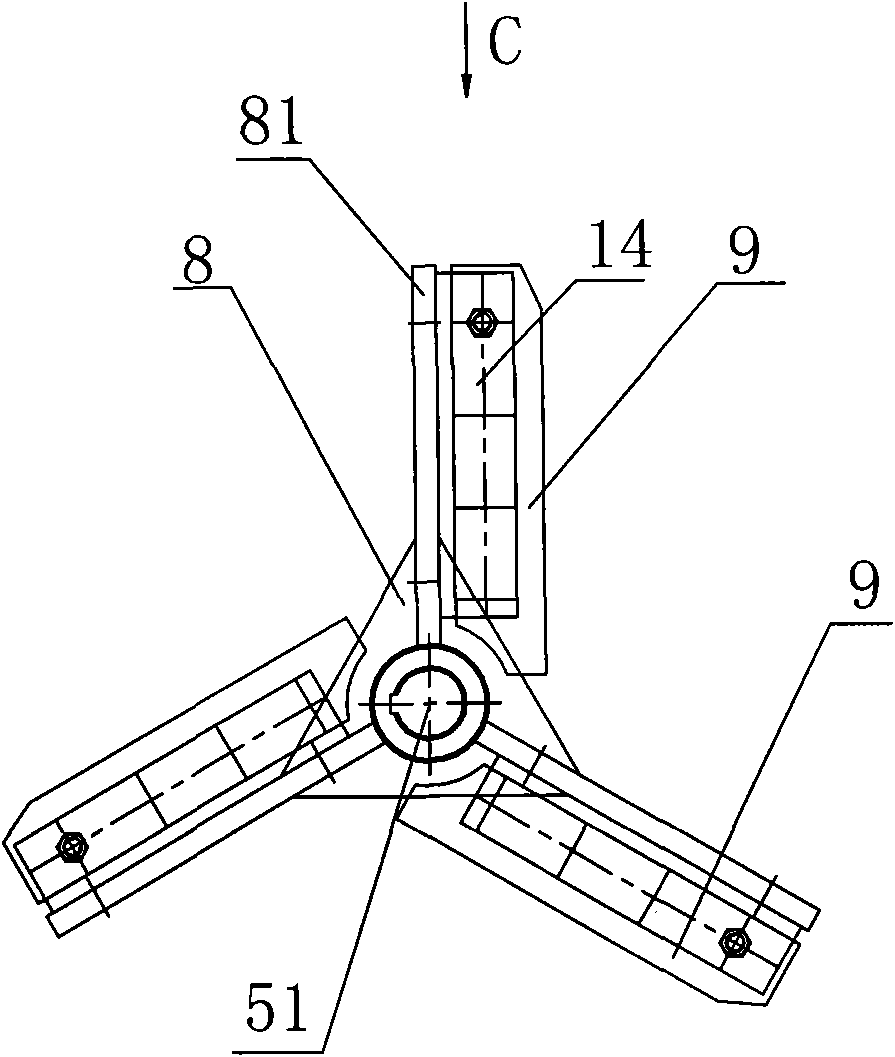

[0021] Figure 1 to Figure 5 Combined with a rough and hard stalk chopping device that can automatically adjust the feeding height, it includes a chopper assembly, a feeding trough 3, a feeding mechanism 4, a throwing device 1, a speed change mechanism 11, a motor 6, and a belt drive Box 5 and Rack 7.

[0022] The chopper assembly includes a chopper housing 2 arranged on the frame 7, the chopper housing 2 is respectively provided with an inlet of the chopper housing 2 and an outlet of the chopper housing 2, and is located at the shredder housing 2. The throwing device 1 above the device housing 2 is in communication with the outlet of the chopper housing 2 . Belt drive box 5 is positioned at the left side of chopper housing 2, and motor 6 positioned at chopper housing 2 below links to each other with power shaft 51 by belt drive box 5, and motor 6 is fixedly installed on the frame 7. The right side of the shredder housing 2 is provided with a feeding mechanism 4 and a speed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com