Quantitative reverse deformation arrangement based method for designing cast model

A technology of anti-deformation and deformation, which is applied in the direction of casting molding equipment, etc., can solve the problems of inaccurate prediction of casting size changes and remaining machining allowances, inconformity with energy saving and consumption reduction, and increasing machining allowances, so as to shorten calculation iterations The number of times, the solution to the lack of machining allowance, and the effect of improving product performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

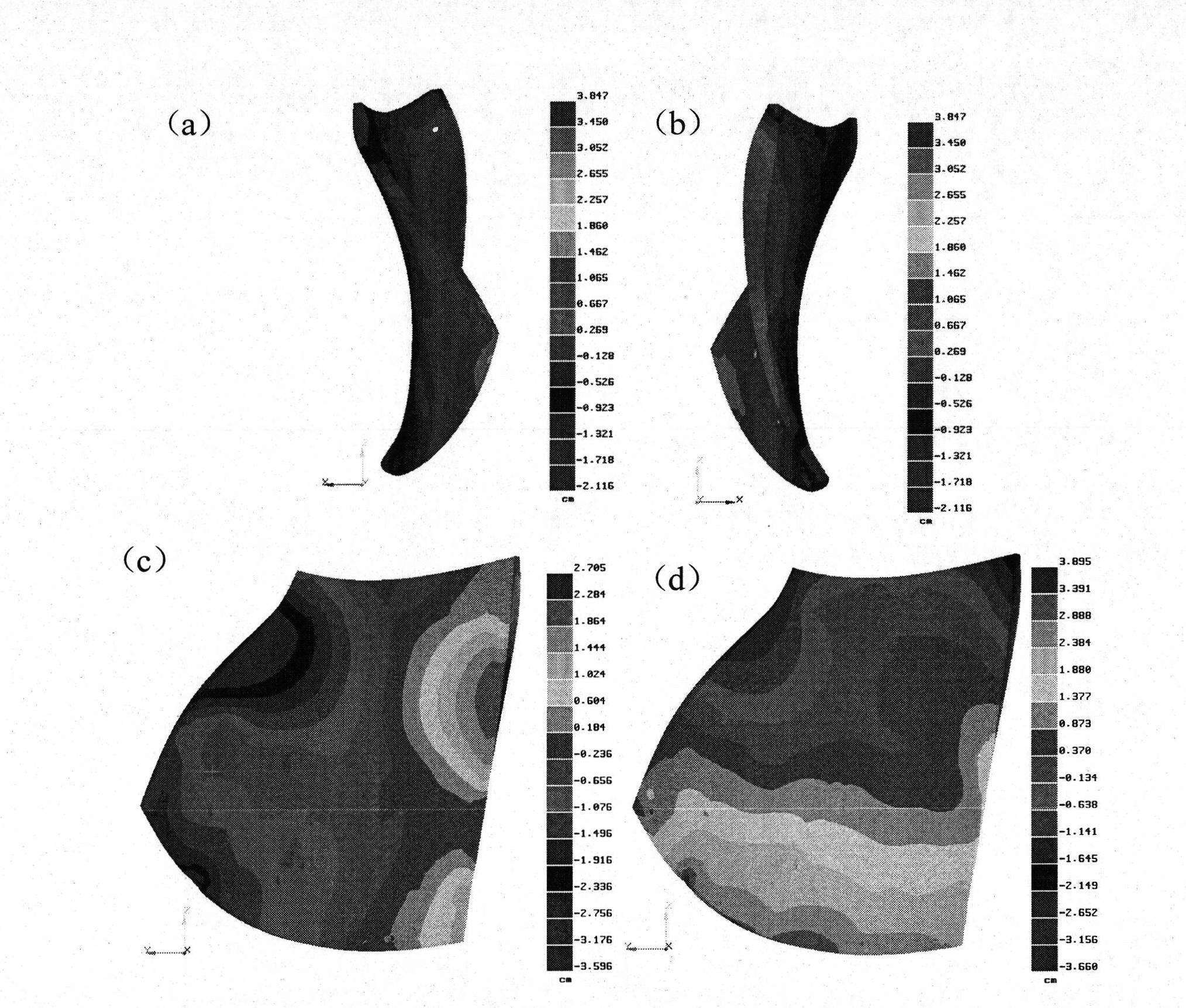

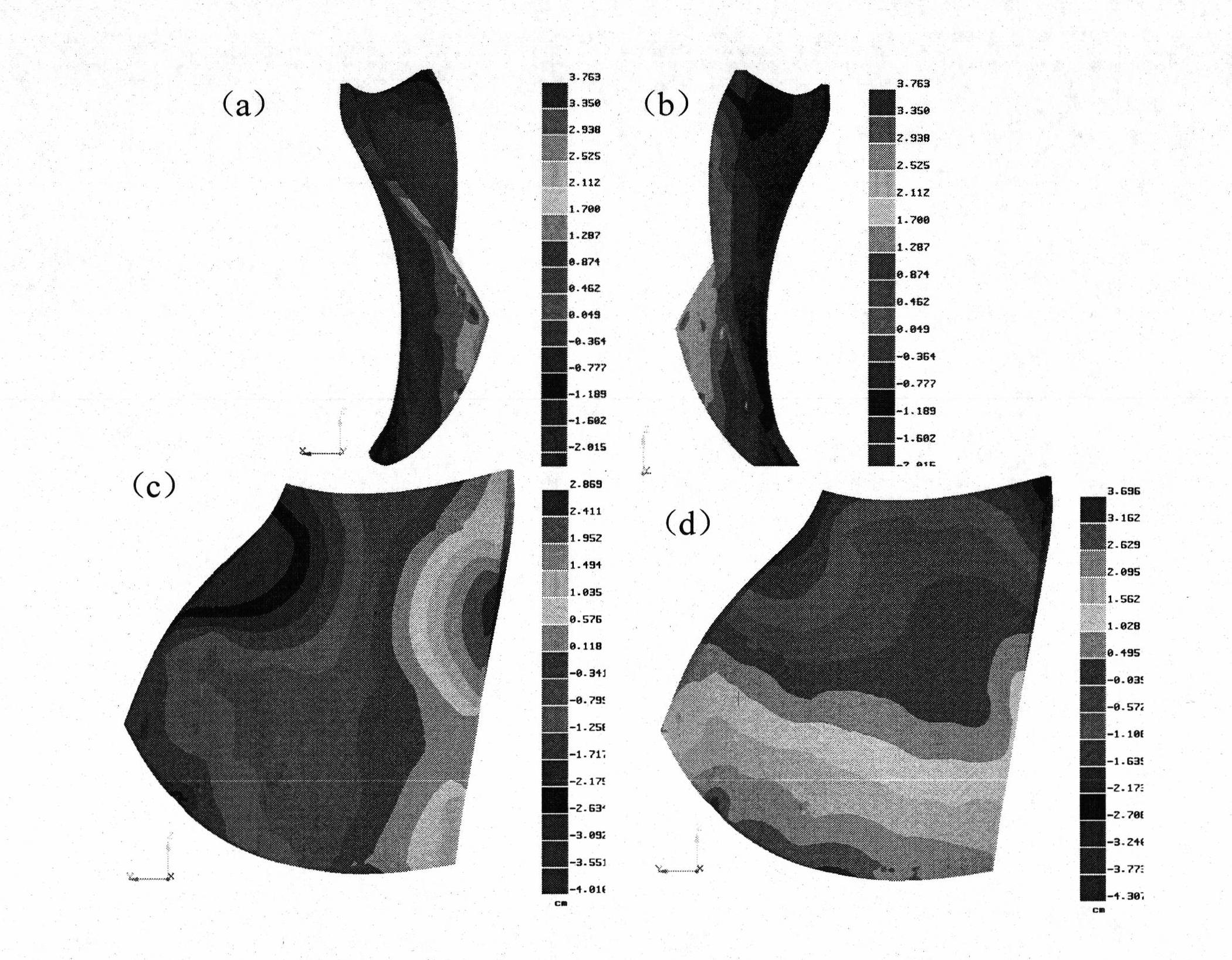

[0038] This embodiment is to design a set of large water turbine blade casting models through the technology of the present invention. The profile size of the blade is: 3400×3400×1100mm, which is used for the runner of 700MW large-scale water turbine. Since the blade is driven by the water flow during the operation of the runner, the profile design is very complicated and the distortion is serious. The complex curved surface shape makes the blade easily deformed in the thermal processing processes such as casting and heat treatment, and it is difficult to predict the deformation trend and amount of blade deformation based on experience. The original technology can only ensure that it will not appear in the end by increasing the casting allowance. The phenomenon of "lack of meat" greatly increases the manufacturing cost and the difficulty of subsequent mechanical processing. In this embodiment, the die design of the blade is carried out according to the design target that the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com