Compound co-extrusion conical screw extruder

A conical screw and extruder technology, which is applied in the field of compound co-extruded conical screw extruders, can solve the problems of affecting the appearance and quality of products, large equipment footprint, and large equipment investment, so as to avoid weld lines” traces, improved conveying capacity and output, and easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] specific implementation plan

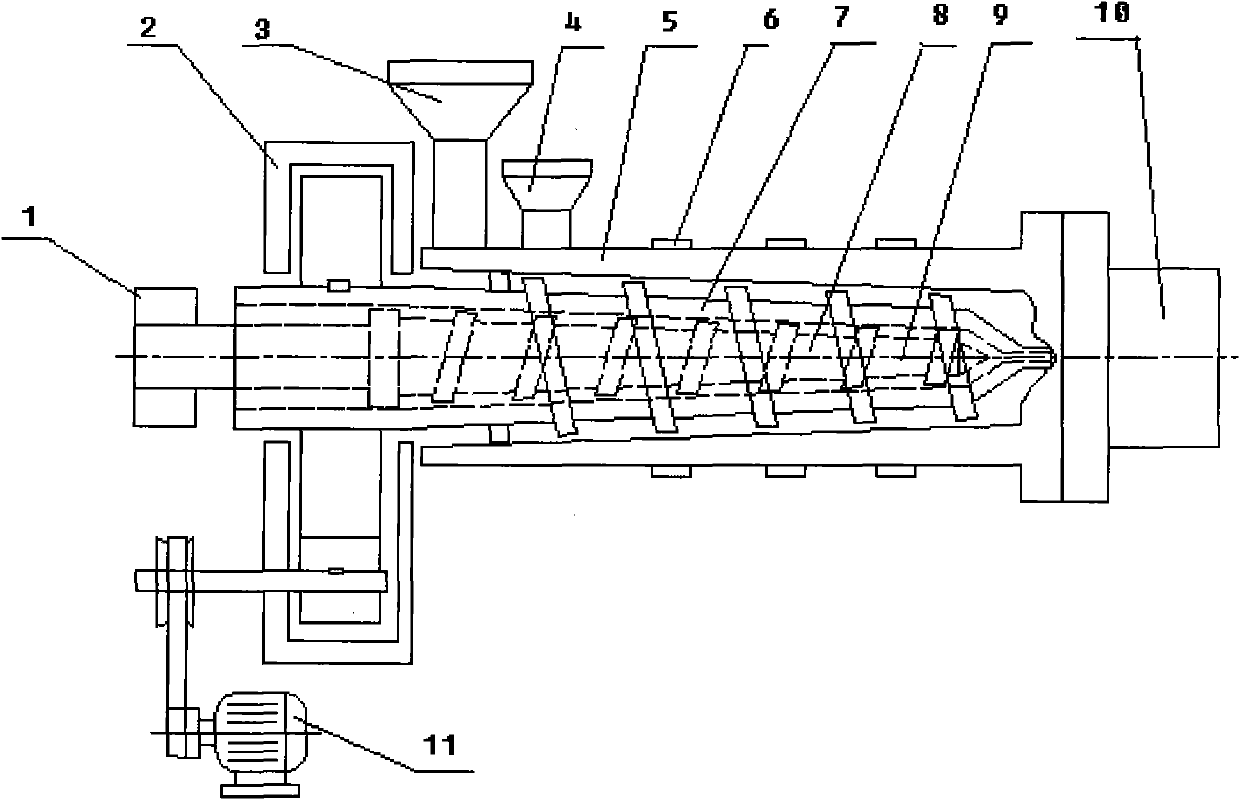

[0015] The composite co-extrusion conical screw extruder of the present invention mainly comprises: motor 11, reduction box 2, machine barrel 5, outer screw 7, inner screw 8, stator 1, first feeding port 4, second feeding port 3, machine barrel Heating ring 6, internal screw heating device 9, die 10.

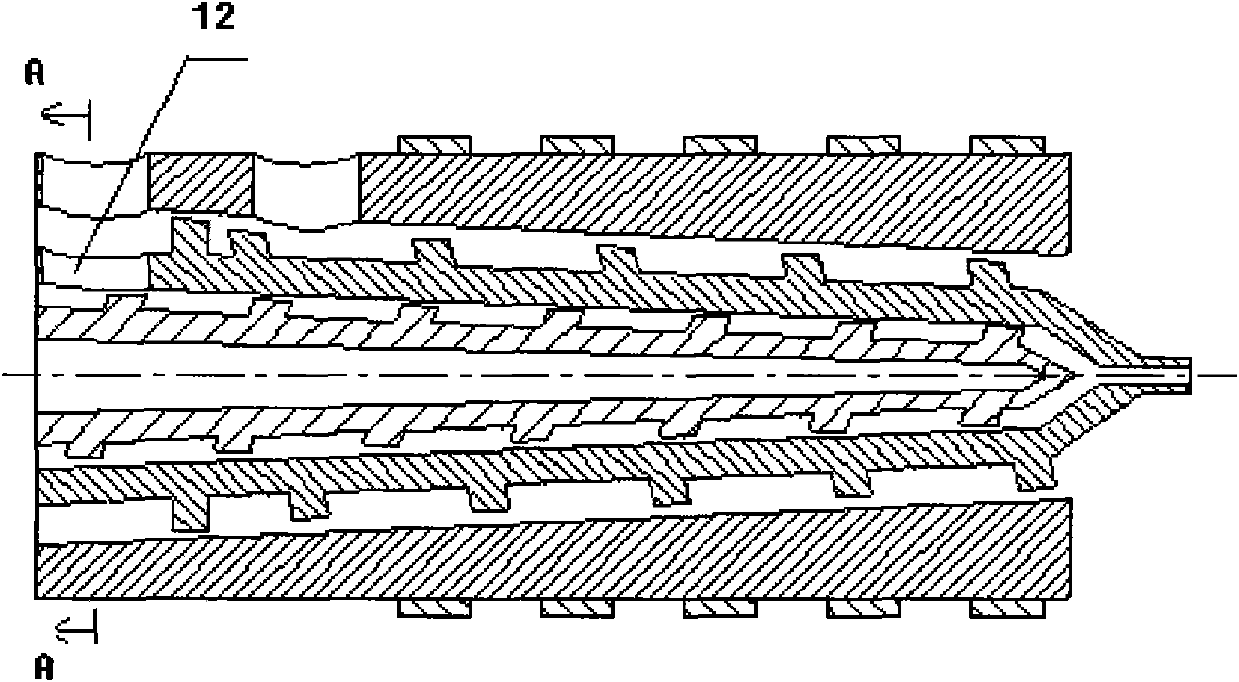

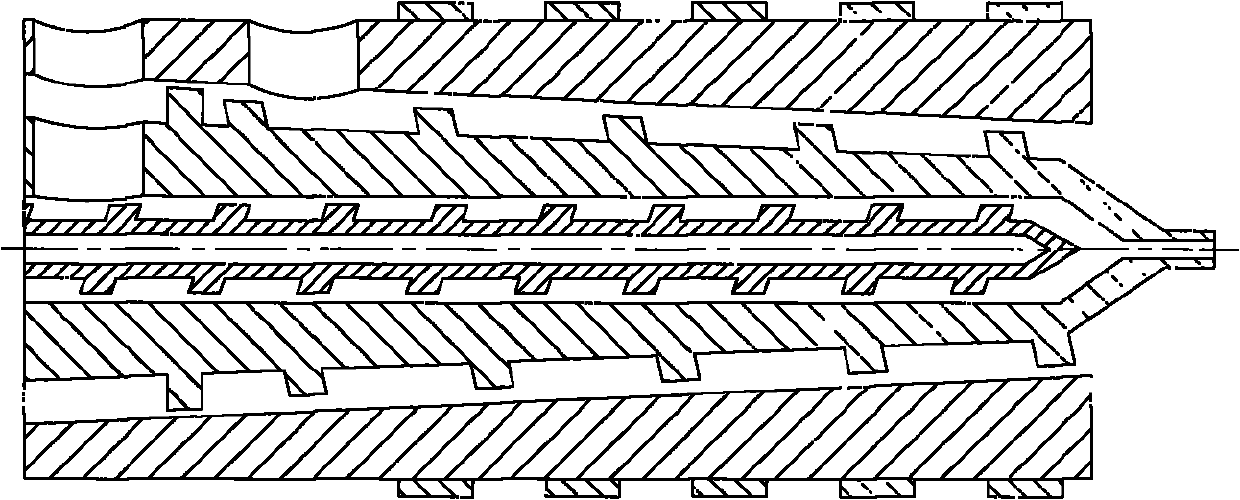

[0016] How it works (see figure 1 ): When the motor drives the outer screw to rotate, it produces an opposite rotational motion with the inner screw (fixed or driven by the motor alone). A material is fed from the hopper 4, and enters the external screw for extrusion, transportation, plasticization, and melting. Another material is added from the hopper 3, and enters the closed material storage room formed by the annular groove at the front end of the outer screw and the inner surface of the barrel, distributed along the circumferential direction of the outer screw annular groove, and enters from the feeding hole 12 of the annular storage ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com