Device for storing and transferring automotive body-in-white sheet metal

A transfer device and body-in-white technology, which is applied in the field of process equipment, can solve the problems of waste of storage space for sheet metal, insufficient storage space for sheet metal, and reduced production efficiency, so as to achieve the goal of occupying less plane space, eliminating potential safety hazards, and lightweight design Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

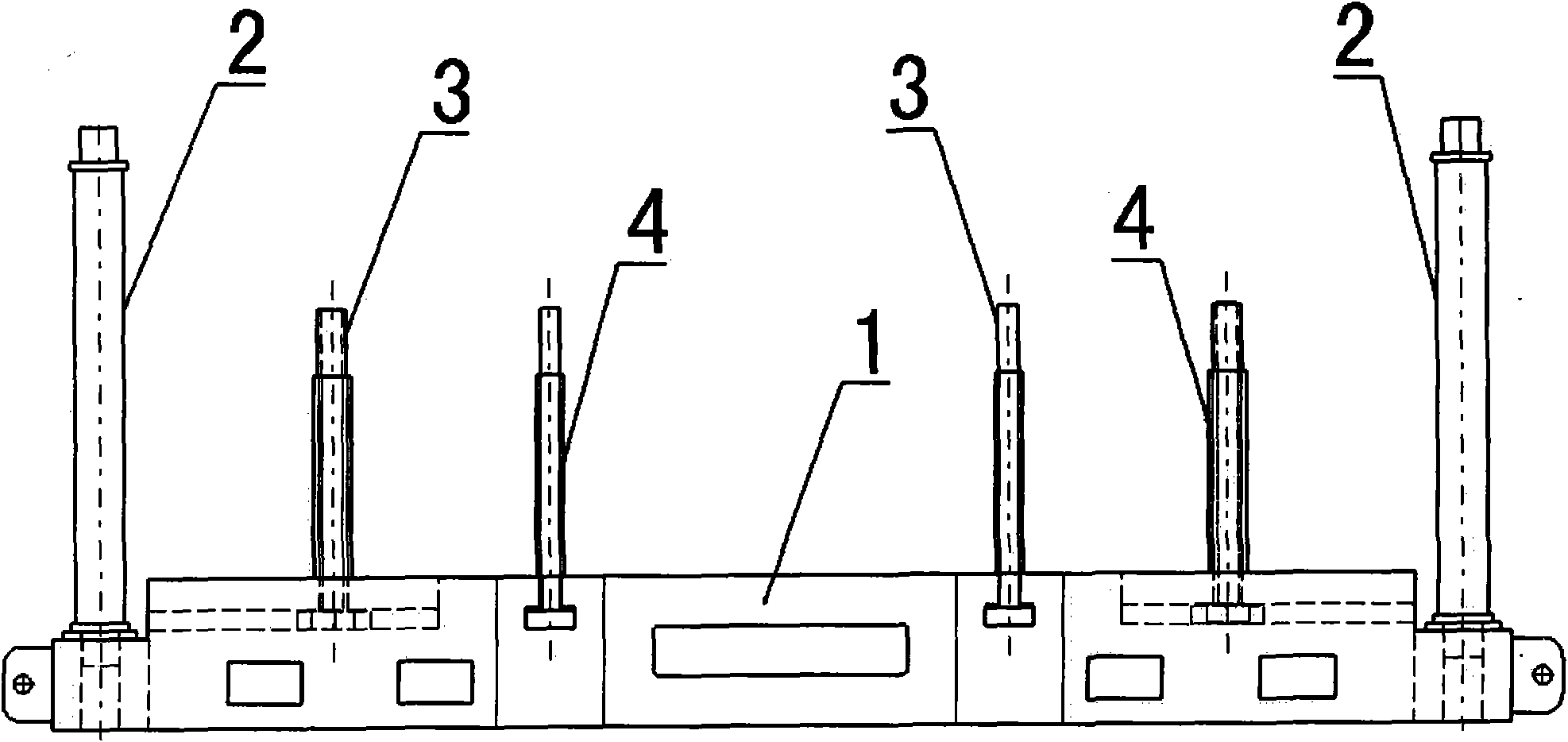

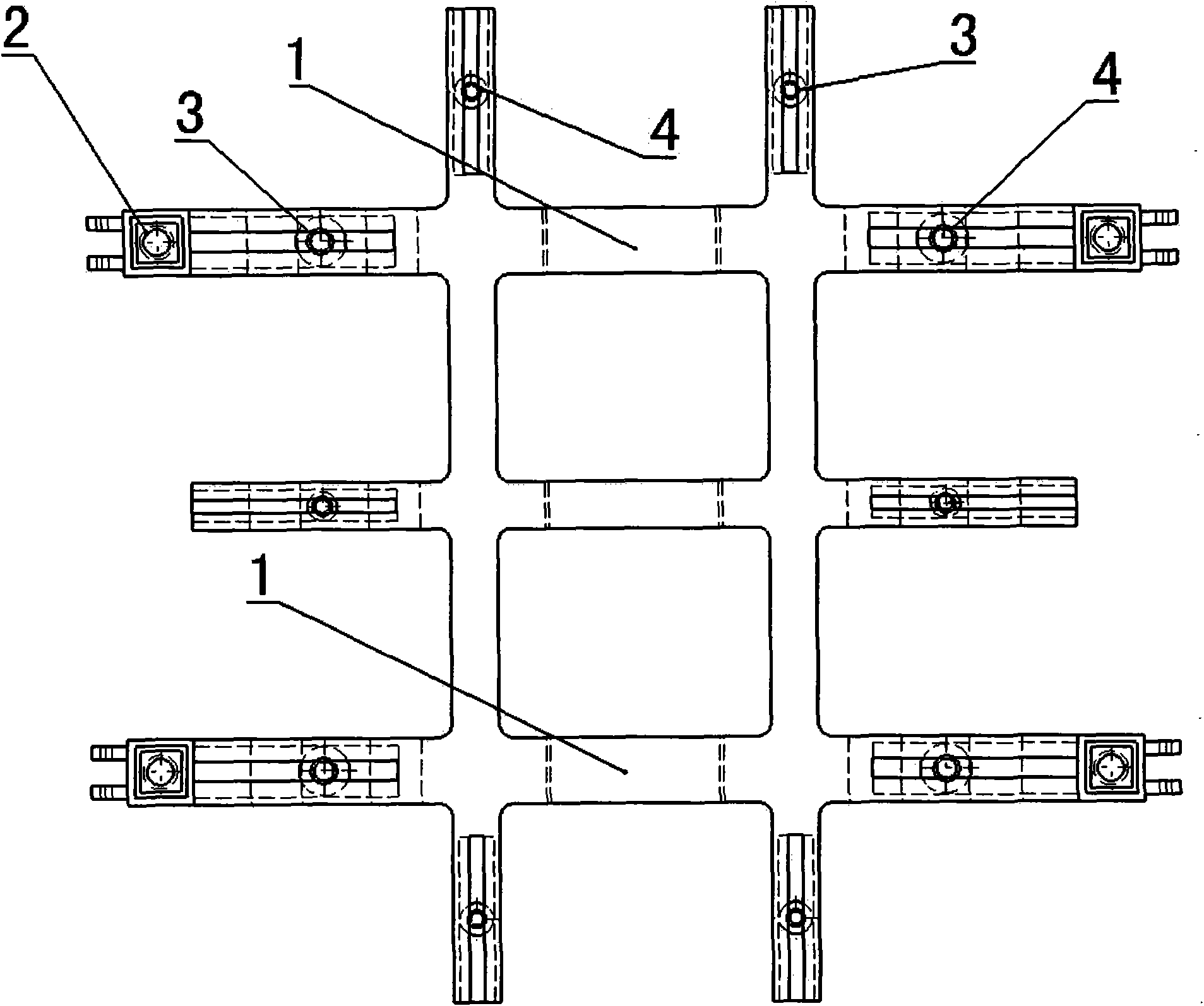

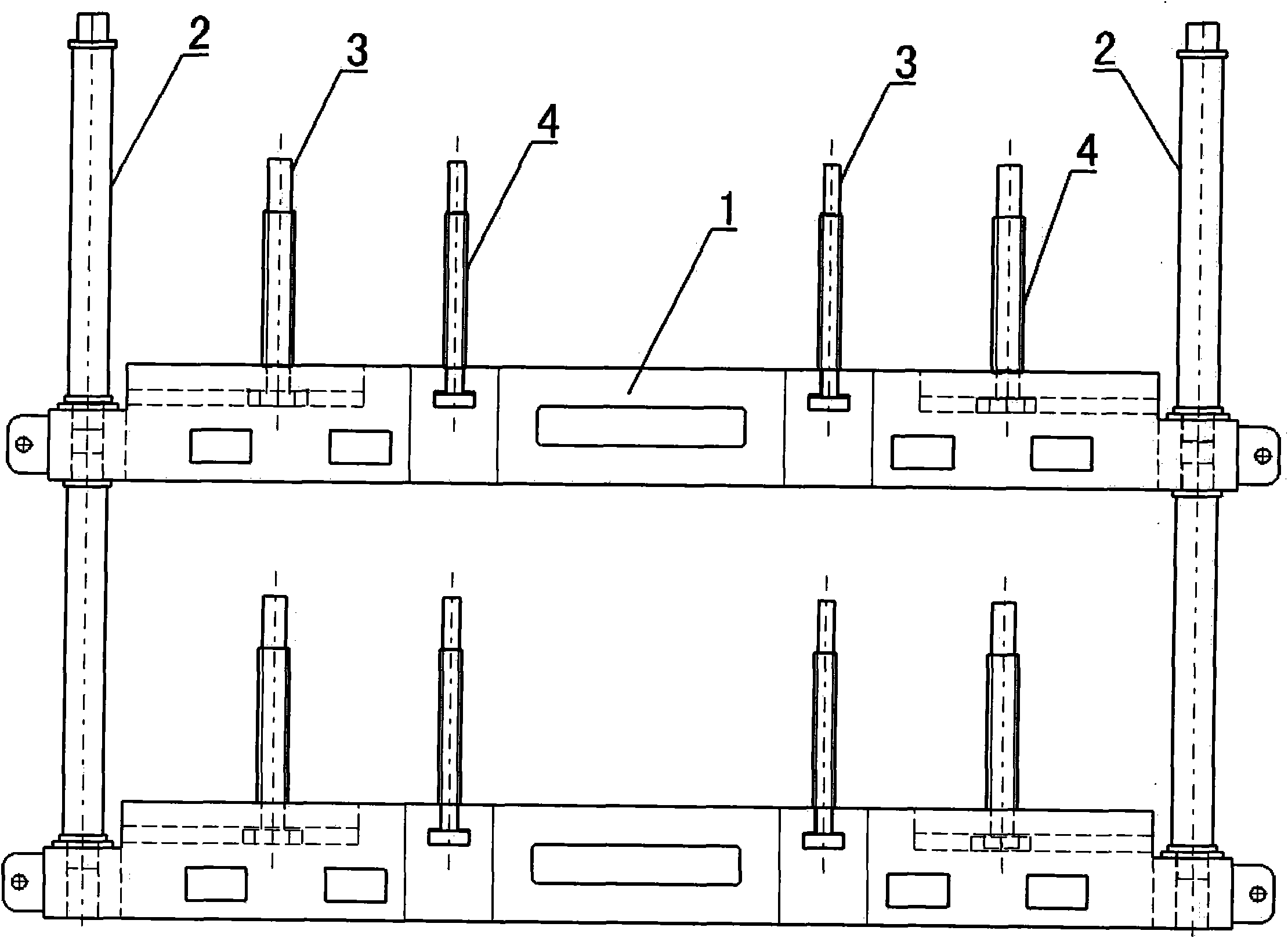

[0030] see figure 1 , figure 2 , the automobile body-in-white sheet material storage and transfer device includes a "well"-shaped frame base 1, a reinforcing rod is connected to the middle of the "well"-shaped frame base 1, and the two ends of the reinforcing rod protrude outwards, and the six protruding rods of the base 1 The two extension rods of the reinforcing rod and the reinforcing rod are both base rods, and an inverted T-shaped slot is provided on the upper part of each base rod, and a stopper rod 3 is inserted in the T-shaped slot, and the lower end of the stopper rod 3 is connected with the base The inverted T shape matched by the inverted T-shaped groove on the rod, the stopper rod 3 can slide along the T-shaped groove. The spacing between adjacent base bars is 800mm. The shaft of the retaining rod 3 is equipped with a protective sleeve 4, and the material of the protective sleeve 4 is polyurethane, which can prevent scratches on the installed sheet. The two end...

Embodiment 2

[0034] The spacing between the base rods is 1200mm, and the structural spacing adopts an equidistant design, which is proportionally scaled; the structural features are the same as in Embodiment 1.

[0035] The sheet material storage and transfer device of this size is suitable for parts with a size of 750mm×1500mm-1450mm×2500mm.

Embodiment 3

[0037] The spacing between the base rods is 1500mm, and the structural spacing adopts an equidistant design, which is scaled in direct proportion; the structural features are the same as in Embodiment 1.

[0038] The sheet material storage and transfer device of this size is suitable for parts with a size of 1450mm×2500mm-1600mm×3700mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com