Device and process for separation and purification of methanol synthetic oil containing high-content aromatic hydrocarbon

A technology of methanol-synthetic oil and high-aromatic hydrocarbons, applied in the field of rectification, can solve the problems of high percentage, affecting gasoline quality, and the quality of synthetic oil not meeting the national standard of motor gasoline, so as to improve the quality of oil products, improve economic benefits, Broaden the effect of developing and utilizing the market

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

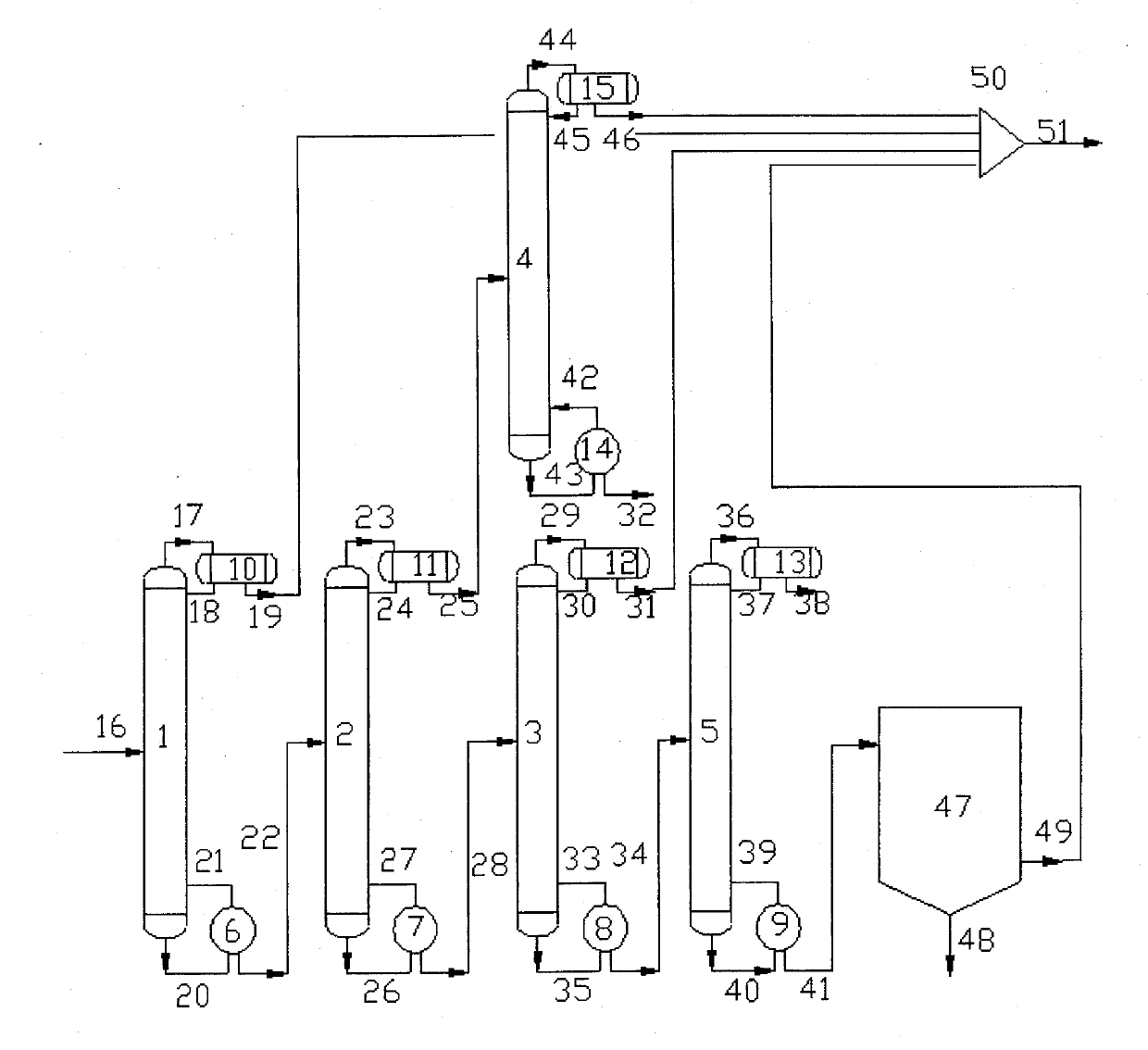

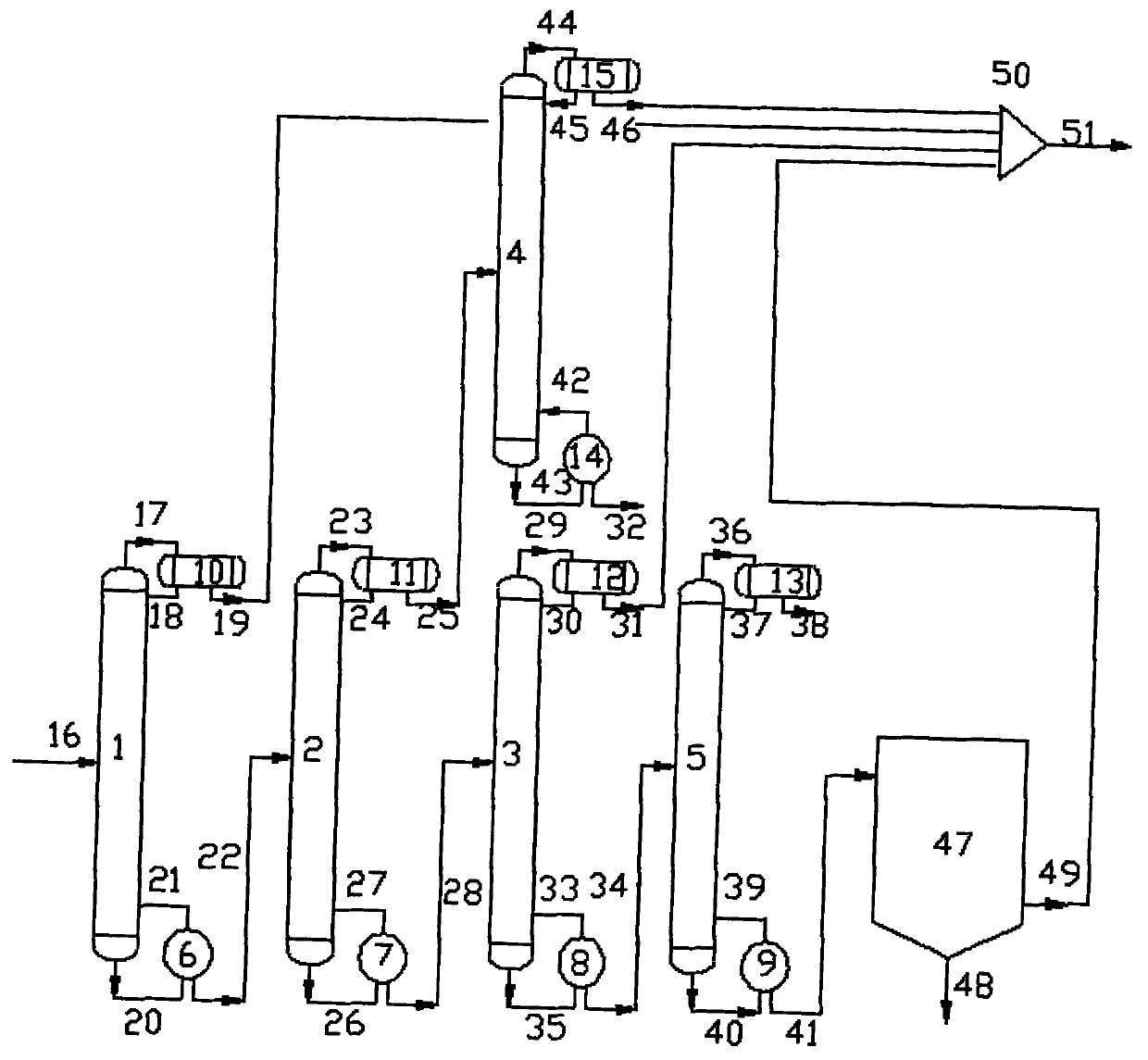

[0020] The light removal tower (1) pressure is controlled at 150KPa, the tower top temperature is controlled at 10.3 ℃, the number of theoretical plates is 87, and the reflux ratio is 3; 97.8 ℃, the number of theoretical plates is 92, and the reflux ratio is 12; The pressure of the toluene refining tower (4) is controlled at 30KPa, the temperature at the top of the tower is controlled at 97.63°C, the number of theoretical plates is 137, and the reflux ratio is 36; the pressure of the toluene refining tower (5) is controlled at 30KPa, and the temperature at the top of the tower is controlled at 126.9°C , the number of theoretical plates is 122, the reflux ratio is 10, and the crystallization temperature of the crystallizer (47) is 20°C.

[0021] The processing capacity of methanol synthetic oil is 250,000 tons / year, and the annual work is calculated based on 8,000 hours:

[0022] product

[0023] product

Embodiment 2

[0025]The light removal tower (1) pressure is controlled at 80KPa, and the tower top temperature is controlled at 13.2 ℃, and the number of theoretical plates is 70, and the reflux ratio is 2; 90.3°C, the number of theoretical plates is 90, and the reflux ratio is 10; the pressure of the trimethylene pre-separation tower (3) is controlled at 40KPa, the temperature at the top of the tower is controlled at 118°C, the number of theoretical plates is 130, and the reflux ratio is 13; The pressure of the toluene refining tower (4) is controlled at 50KPa, the temperature at the top of the tower is controlled at 110°C, the number of theoretical plates is 140, and the reflux ratio is 34; the pressure of the toluene refining tower (5) is controlled at 50KPa, and the temperature at the top of the tower is controlled at 130°C , the number of theoretical plates is 132, and the reflux ratio is 12; the crystallization temperature of the crystallizer (47) is 10°C.

[0026] The processing capa...

Embodiment 3

[0029] Light removal tower (1) pressure is controlled at 100KPa, tower top temperature is controlled at 10.4 ℃, and theoretical plate number is 100, and reflux ratio is 3; 113.5 ℃, the number of theoretical plates is 100, and the reflux ratio is 12; The pressure of the toluene refining tower (4) is controlled at 80KPa, the temperature at the top of the tower is controlled at 128.5°C, the number of theoretical plates is 150, and the reflux ratio is 40; the pressure of the toluene refining tower (5) is controlled at 40KPa, and the temperature at the top of the tower is controlled at 136°C , the number of theoretical plates is 140, and the reflux ratio is 15; the crystallization temperature of the crystallizer (47) is -5°C.

[0030] The processing capacity of methanol synthetic oil is 50,000 tons / year, and the annual work is calculated as 8,000 hours

[0031] product

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com