Fluid jet type weaving machine

A technology of fluid jetting and looms, which is applied to looms, selvedge opening mechanisms, textiles, etc., and can solve problems such as unstable operation of looms and wrong weft insertion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

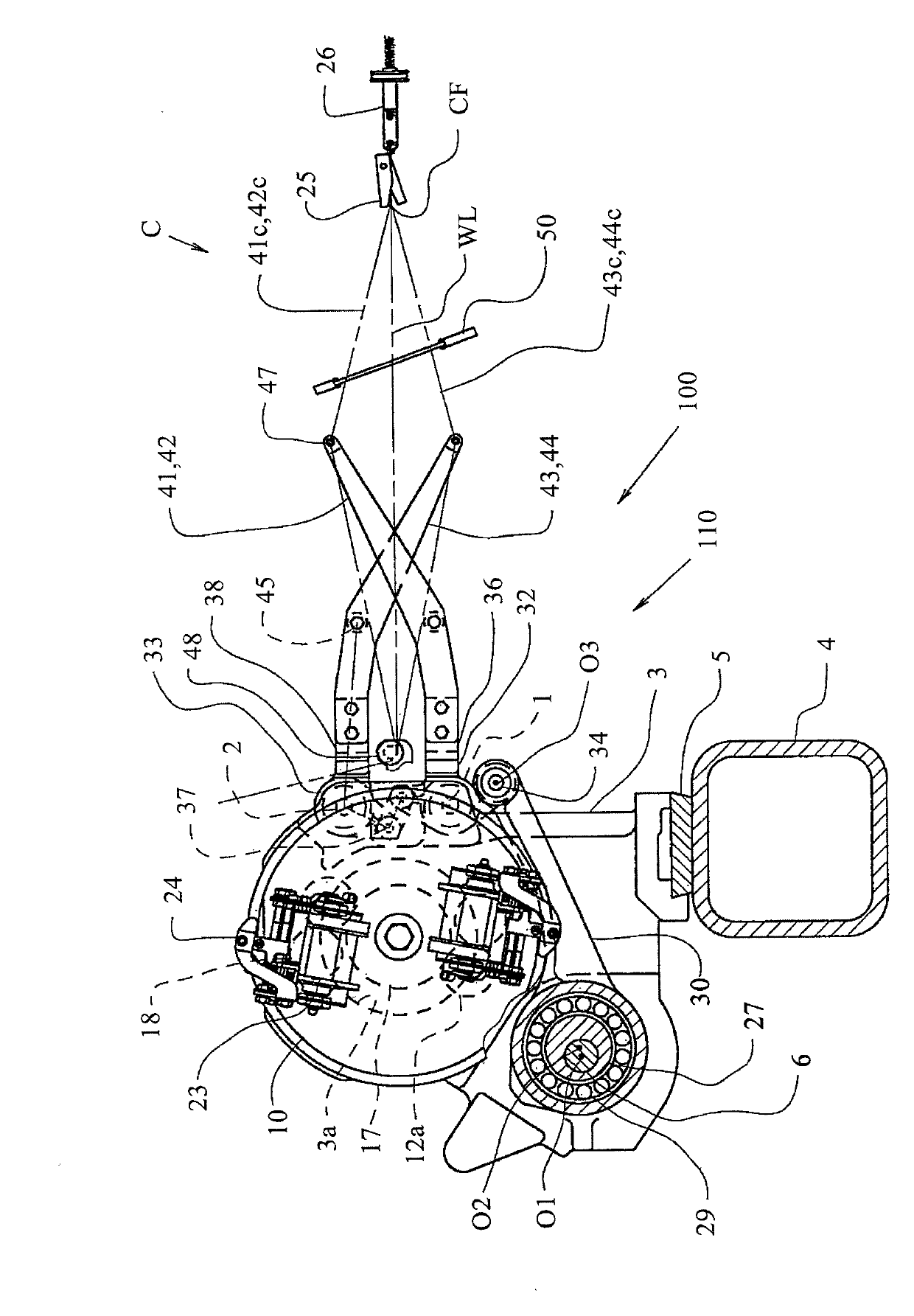

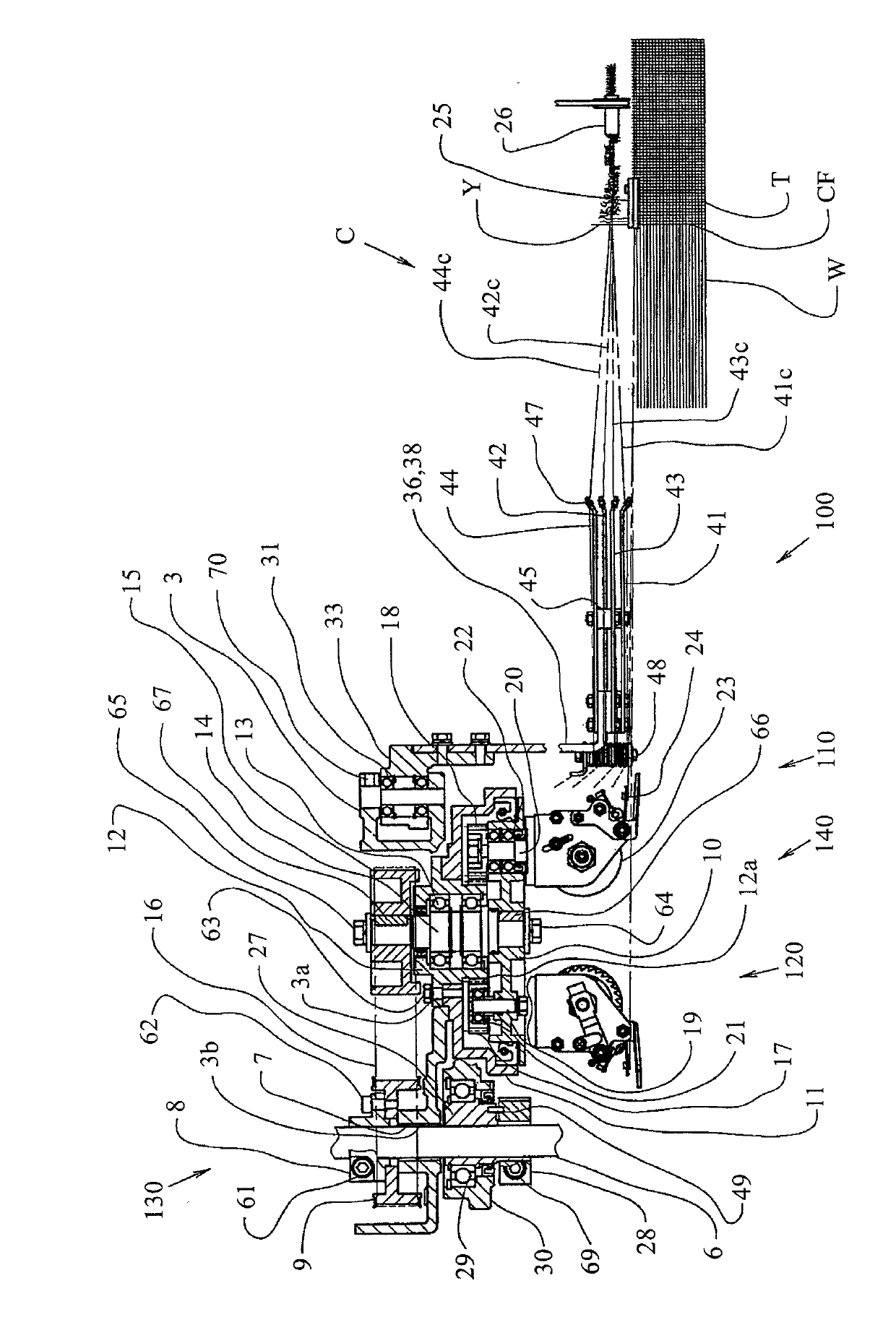

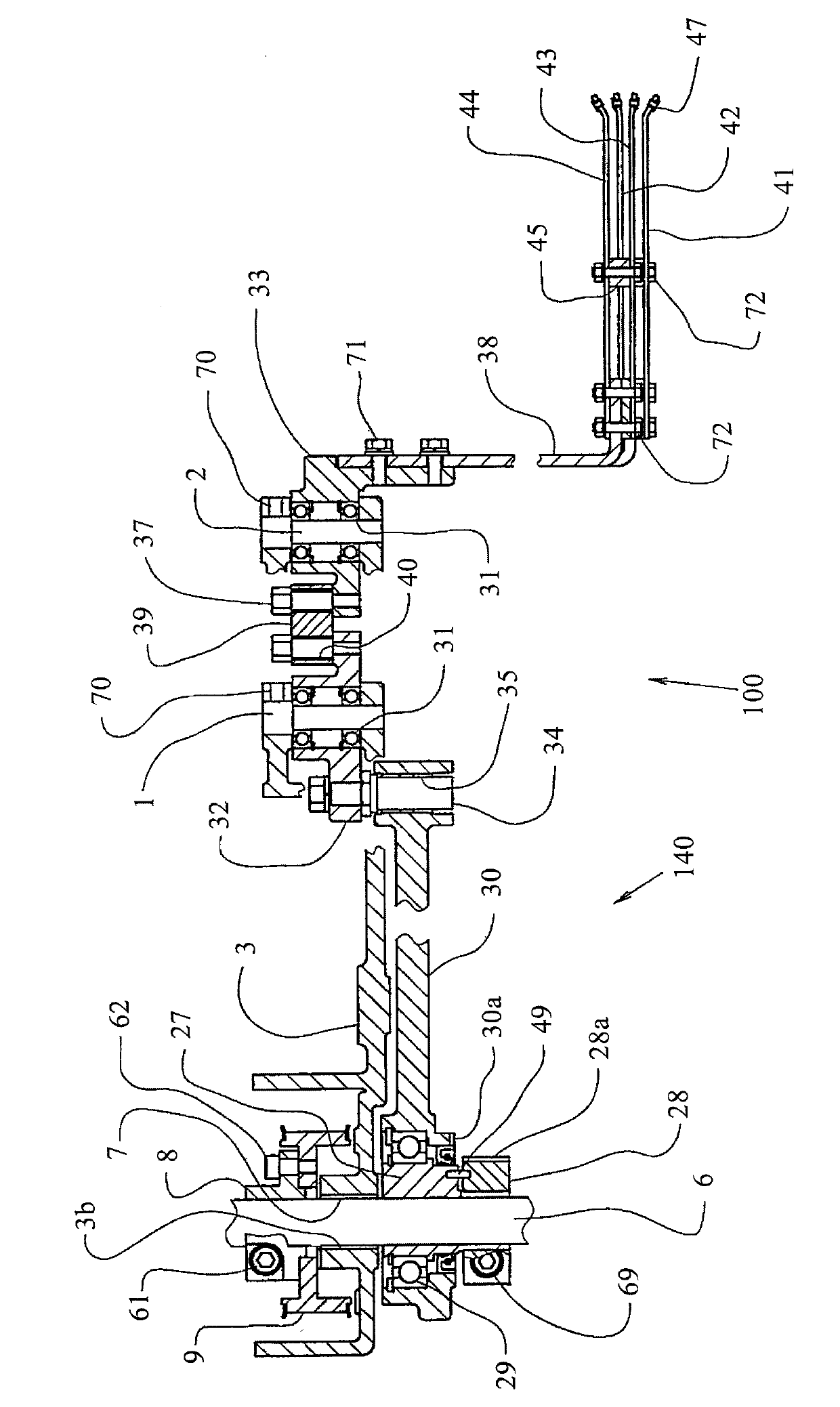

[0042] Embodiments of the present invention will be described below with reference to the drawings. The fluid jet loom of this embodiment is a water jet loom or an air jet loom, and planetary selvage devices 110 are arranged on both sides of the loom, namely, the weft insertion side and the side opposite to weft insertion. On the side opposite to weft insertion, a weft catching edge warp opening device 100 is arranged adjacent to the planetary selvedge device 110 .

[0043] figure 1 It shows the front view of the planetary selvedge device 110 and the weft catcher warp opening device 100 seen from the center of the loom toward the width of the fabric on the opposite side of the weft insertion. Outside the side warp opening device 100, there is also a reed 50, a weft yarn cutting device 25 for cutting the weft yarn Y held by the caught weft side warp C, and a false twist spindle device 26 for false twisting and catching the weft side warp C. The weft catching side warp opening...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com