Self-locking device and self-locking prestressed anchor cable with the self-locking device

A self-locking device and anchor cable technology, which is applied in the installation of anchor rods, sheet pile walls, excavation, etc., can solve the problems of slow performance of special emergency engineering effects, ineffective use of prestressed anchor cables, and sudden accidents, etc. Achieve the effect of preventing sudden failure accidents, improving the distribution of anchorage stress field, and uniform load distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

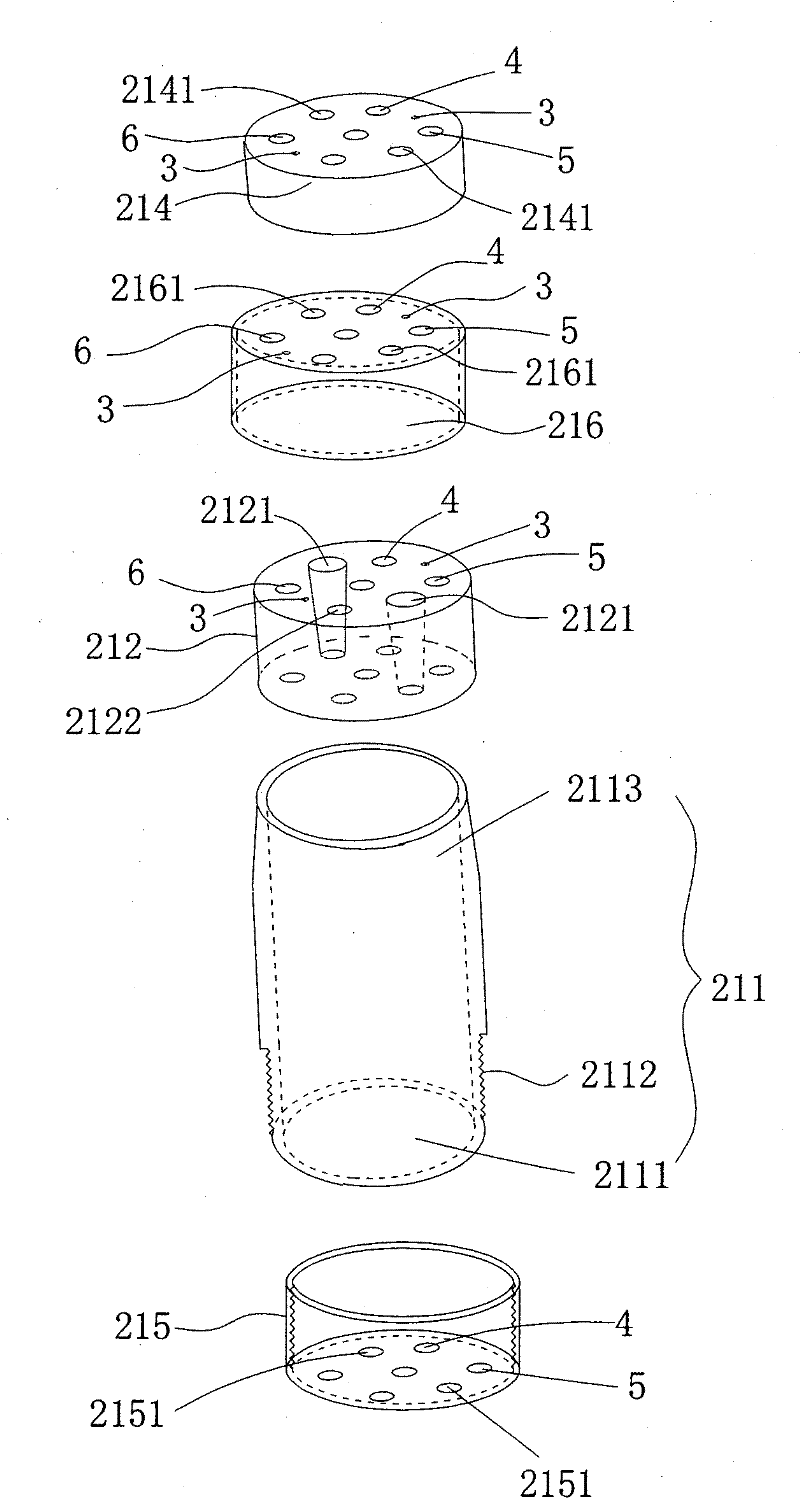

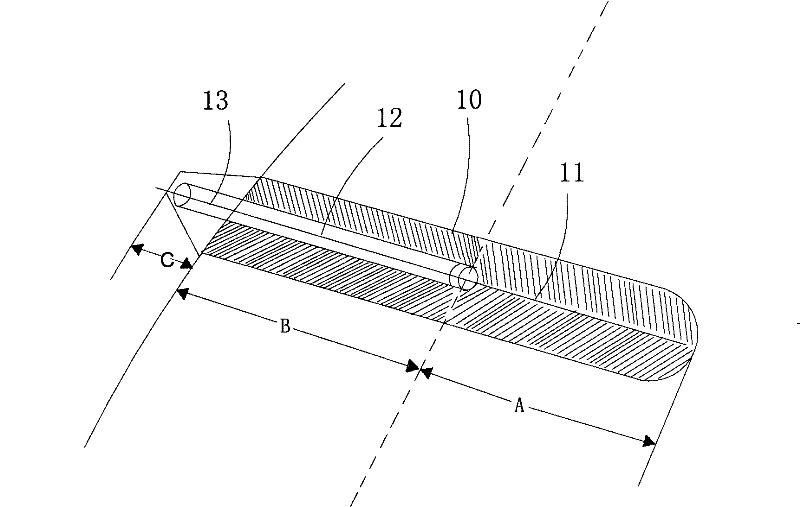

[0021] The self-locking type prestressed anchor cable of the present invention is that a self-locking device is arranged on the free section of the conventional anchor cable structure, and through the locking effect between the self-locking device and the anchor cable, the self-locking device and the rock (soil) layer around the hole The bond strength between them is transferred to the anchor cable, thus providing self-locking load.

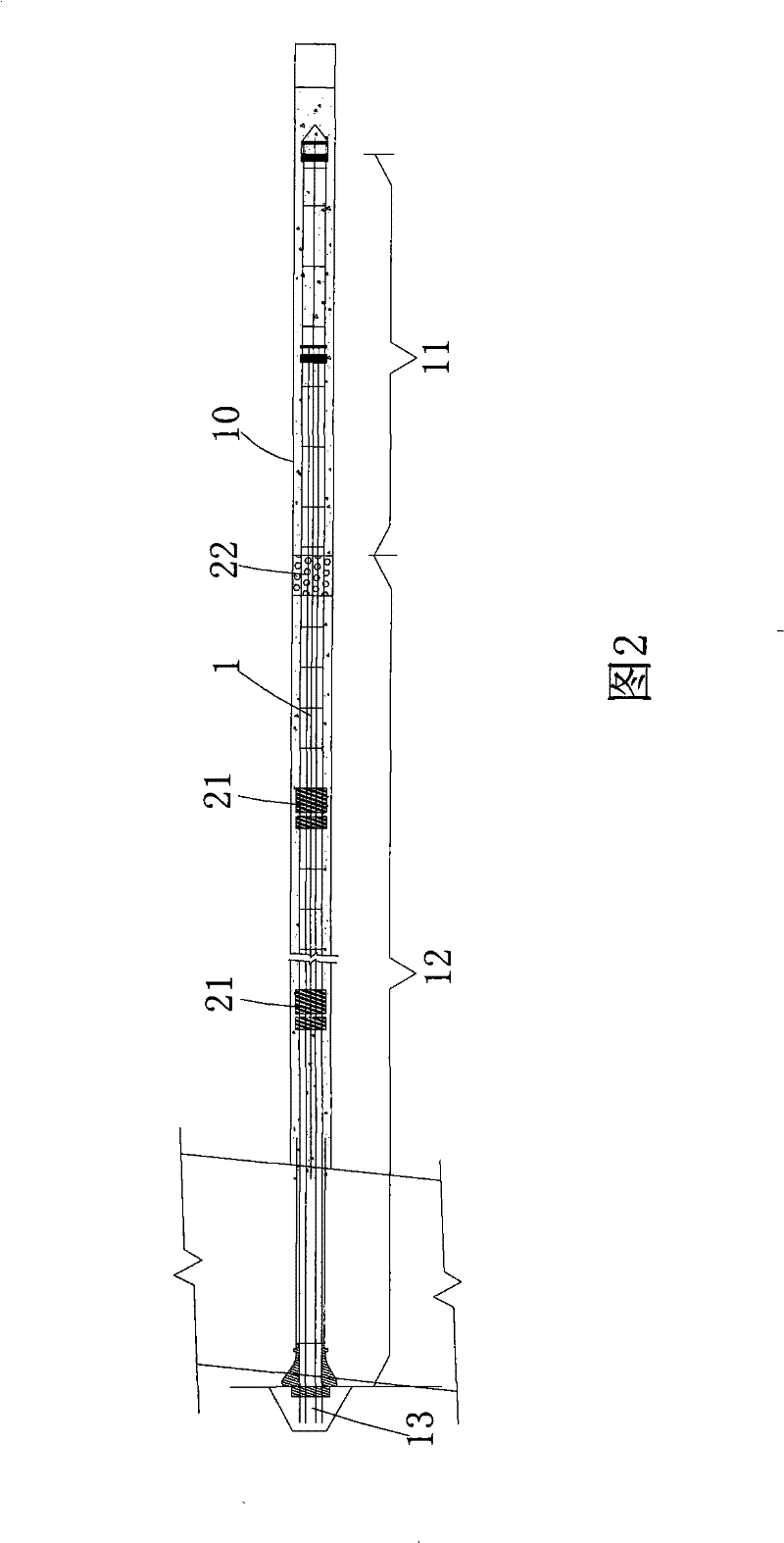

[0022] figure 2 Shown is the structural representation of the self-locking prestressed anchor cable of the present invention, as shown in the figure, the anchor cable 1 of steel strand weaving is buried in the anchor hole 10, and the anchor cable 11 is composed of an anchor section 11, a free section 12 and an anchor cable. The head 13 is composed of three sections, the anchor hole 10 is grouted, the anchor section 11 is firmly bonded to the wall of the anchor hole 10 through the grout, and the anchor head 13 is fixed at the hole through the rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com