Dehumidifying device for hollow stationary blade of steam turbine through heating and blowing

A hollow vane, dehumidification device technology, applied in mechanical equipment, engine components, machines/engines, etc., to achieve the effect of reducing water erosion, simple structure, and easy to implement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with accompanying drawing, the present invention is described in further detail:

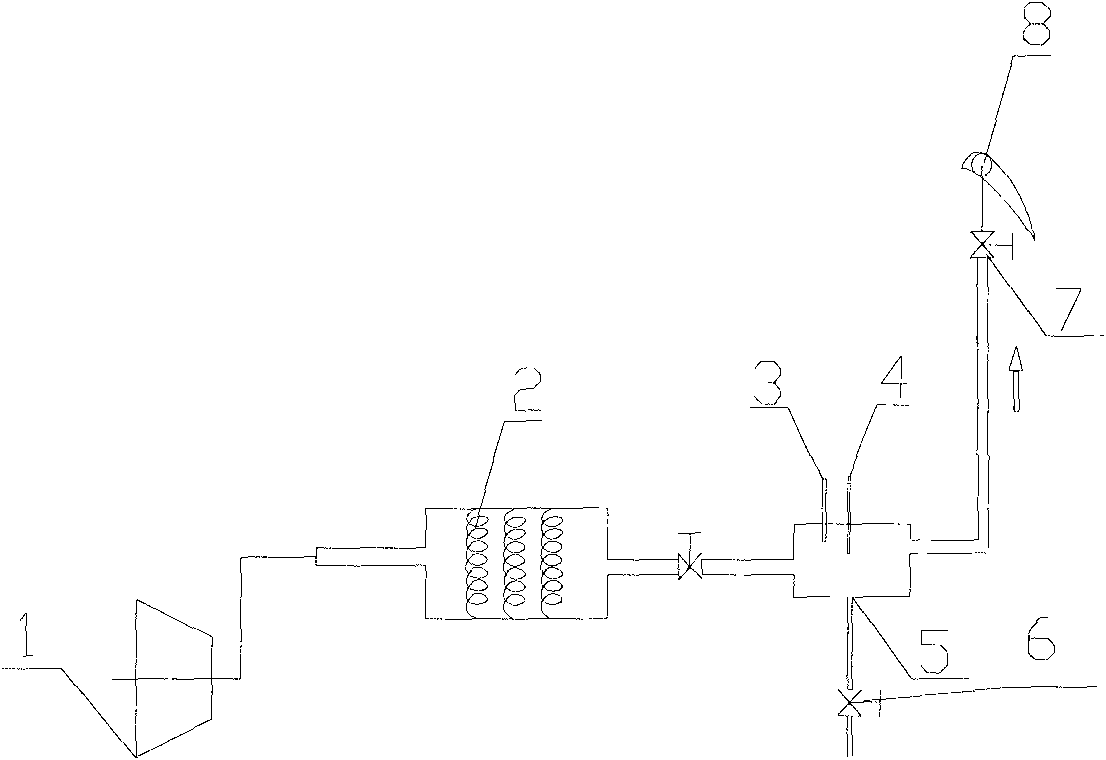

[0017] refer to figure 1 , a steam turbine hollow vane internal heating and purging dehumidification device, the hot air used for heating and purging is completed by an air pump 1, an electric heater 2, a small plenum chamber 5 and some regulating valves 6 and 7, and the air The pump continuously sends air into the heater, and the heater heats the air to a certain temperature. A small plenum is used to stabilize the pressure and adjust the hot air to the required temperature 3; the hot air pressure 4 is adjusted as needed.

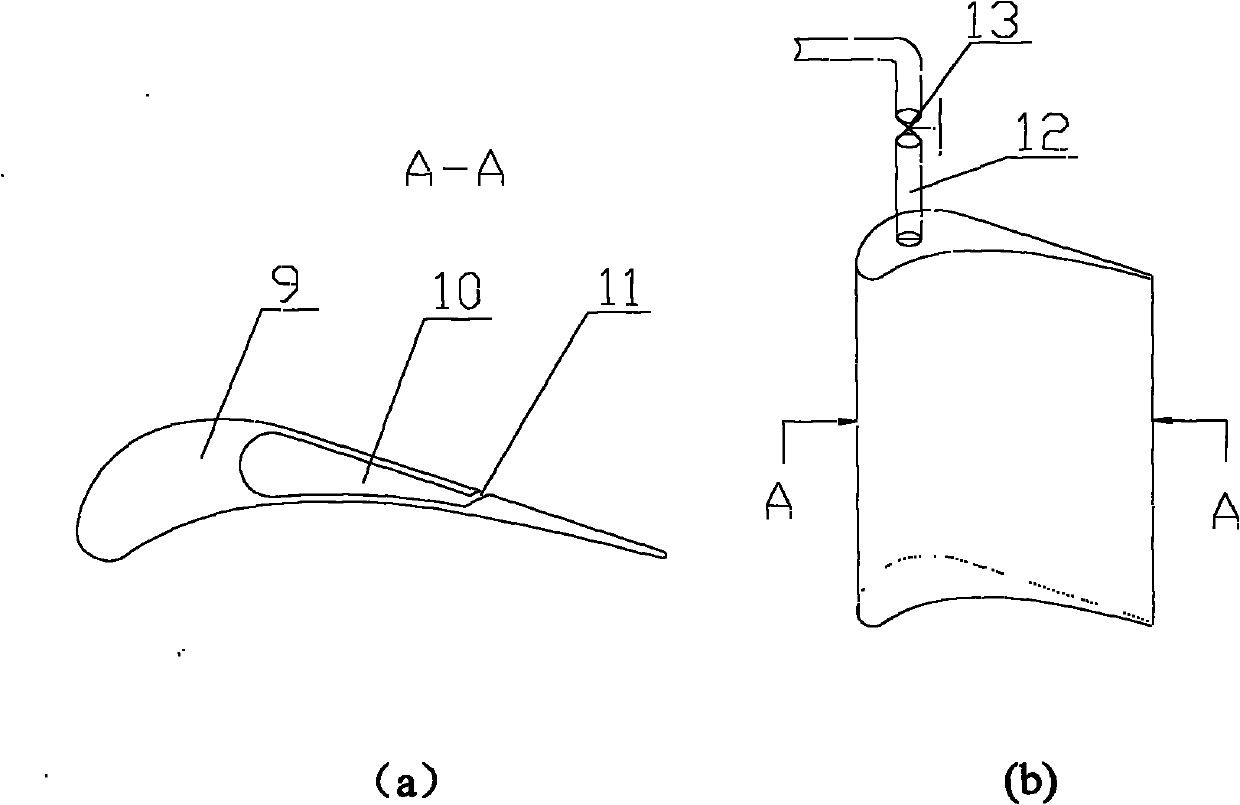

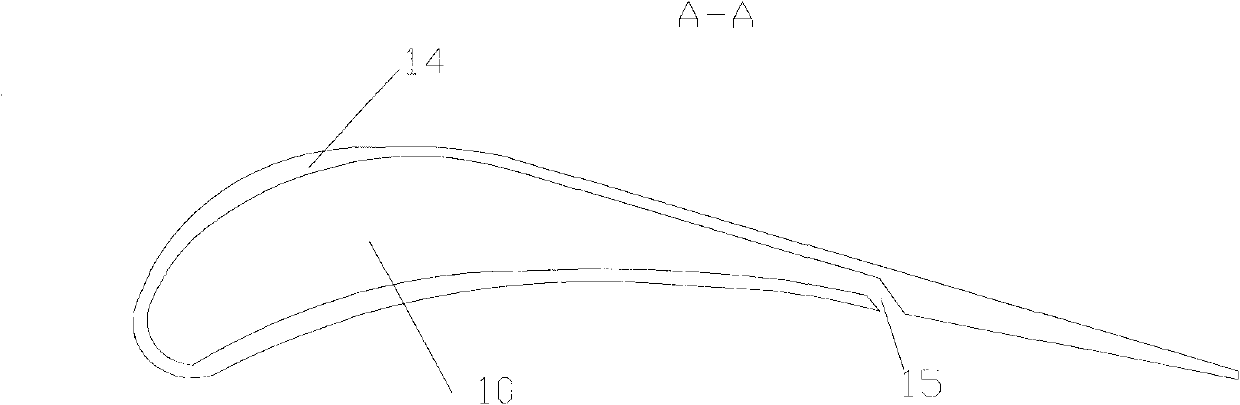

[0018] refer to figure 2 , the hollow vane includes machining the vane 1 of the wet steam stage of the steam turbine into a hollow chamber 2, and there is a purge slit 3 on the inner arc or back arc or the steam outlet side of the vane, and the purge slit 3 is connected with the hollow chamber of the vane 2 communicate with each other, a steam ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com