Low-temperature ultraviolet curing equipment

A curing equipment, UV technology, applied in printing, printing machine, surface pretreatment, etc., can solve problems such as deformation of heat-labile substrates, affecting product quality, safety accidents, etc., to eliminate substrate deformation and improve performance consistency , eliminate the effects of cyclical changes and fluctuations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

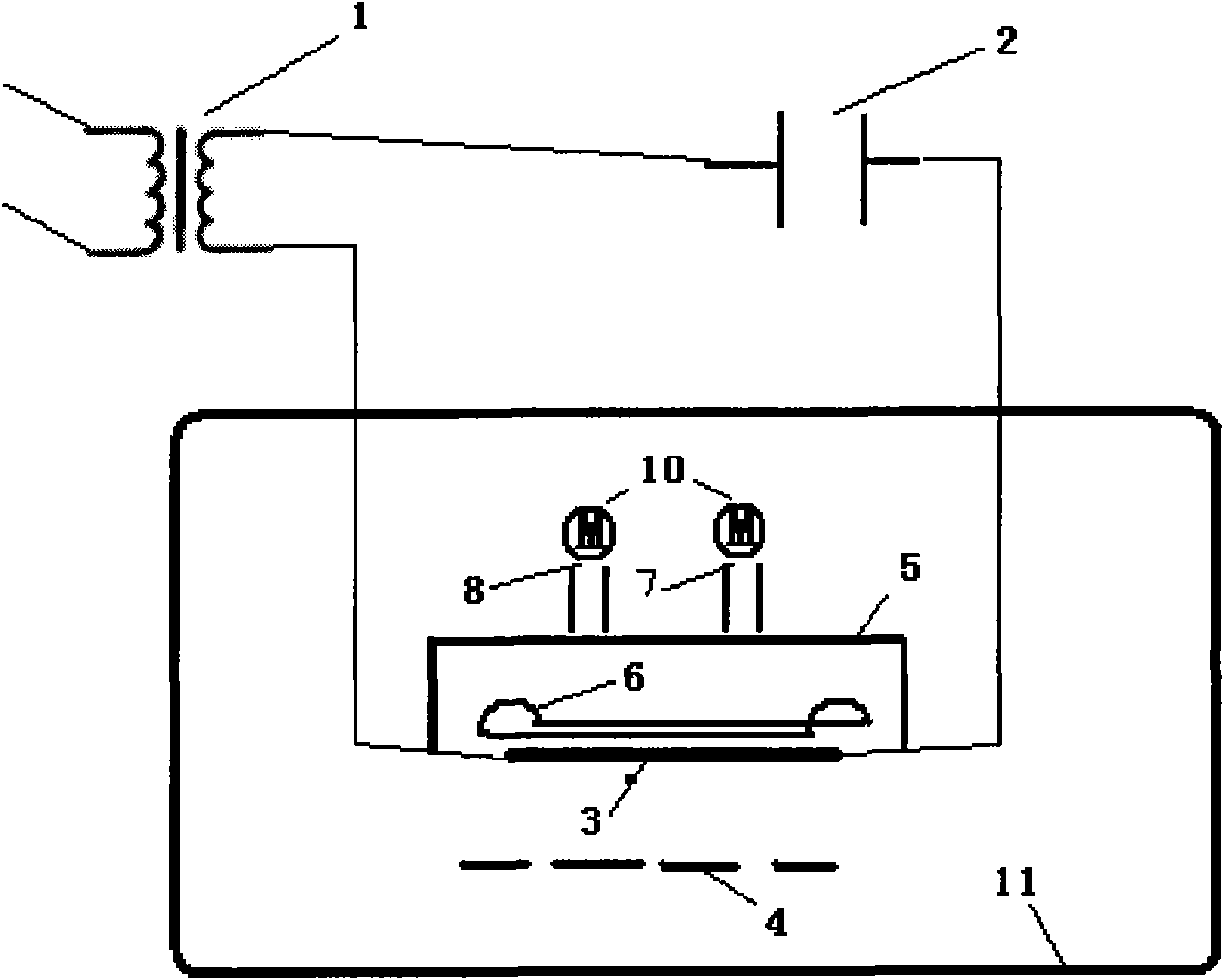

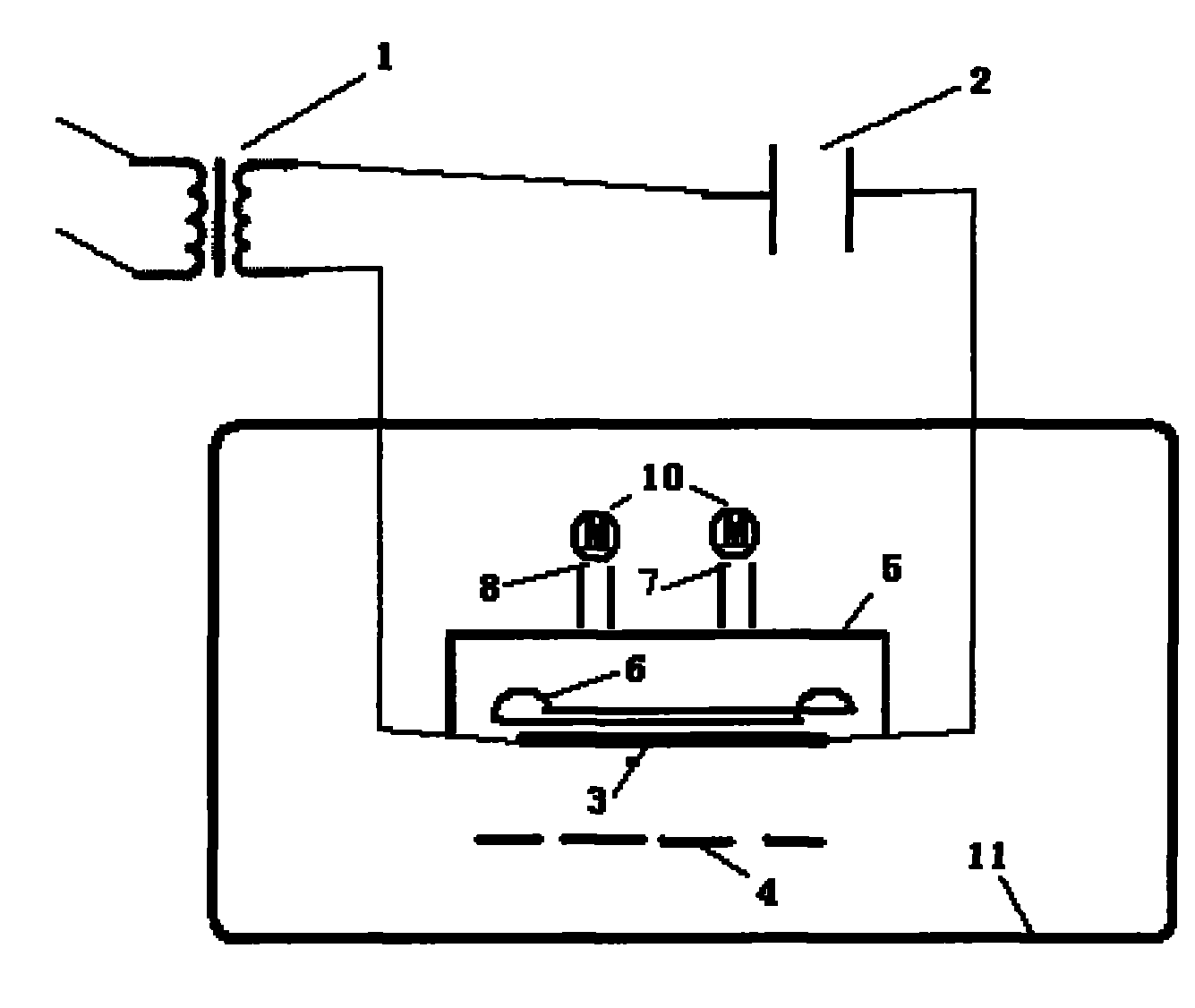

[0015] The low-temperature UV curing equipment uses a 15kw transformer (input voltage 380V, output voltage 2kV), a 12μF (microfarad) capacitor, and a 15kw UV lamp.

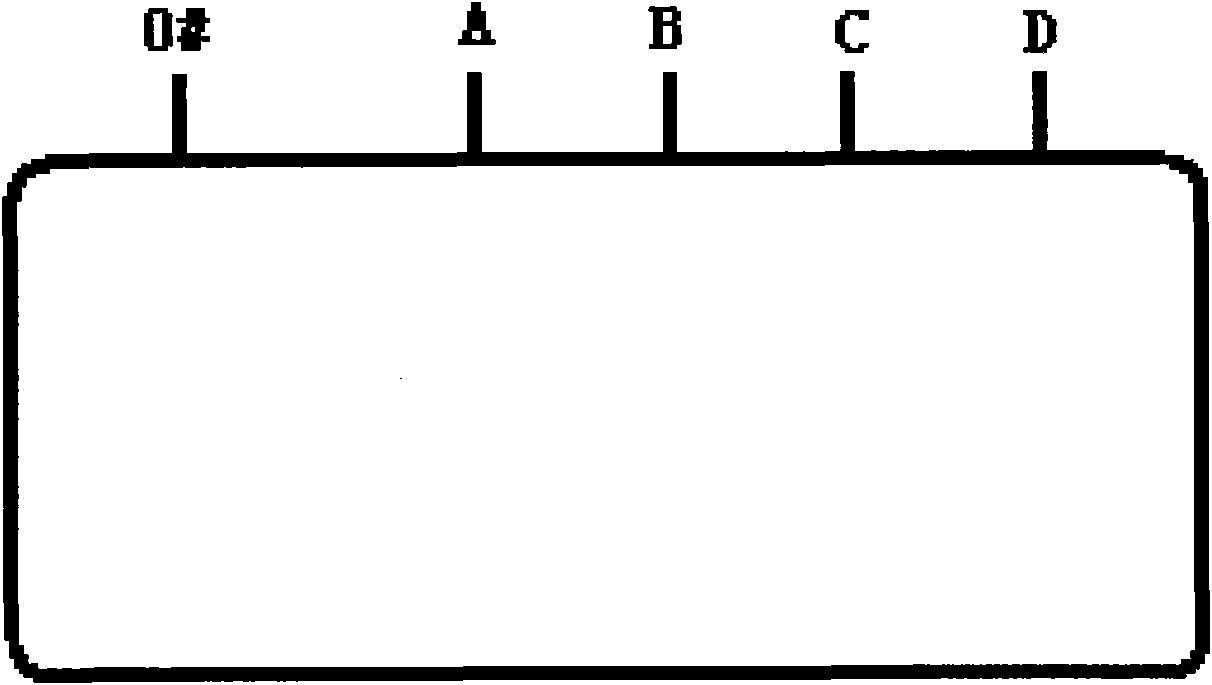

[0016] Among them, the capacitor is divided into four sub-capacity terminals of 1μF, 2μF, 3μF, and 6μF ( figure 2 A, B, C, D four terminals, 0 terminal is the common terminal), realize the use capacity of 1 ~ 12μF through different wiring methods, and realize the terminal current of the ultraviolet lamp to be adjusted within the range of 0.75 ~ 9A, so that the cured product The UV energy on the surface is 75-900mj / cm 2 The adjustment, connection and corresponding relationship between them are as follows:

[0017]

[0018] The UV curing equipment in this example can keep the ambient temperature of the object to be cured below 45°C, realize low-temperature UV curing, and ensure that the properties of the substrate and the cured layer are not affected.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com