Roller bed conveying line installed on portal frame

A conveyor line and gantry technology, applied in the direction of rollers, conveyors, conveyor objects, etc., can solve problems such as the inability to ensure the smooth implementation of the bogie maintenance process, and achieve the effect of large carrying capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

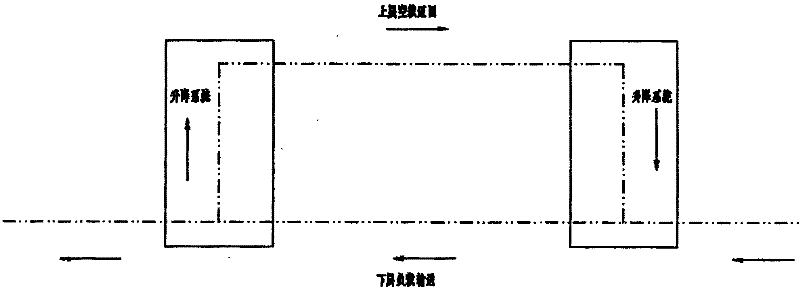

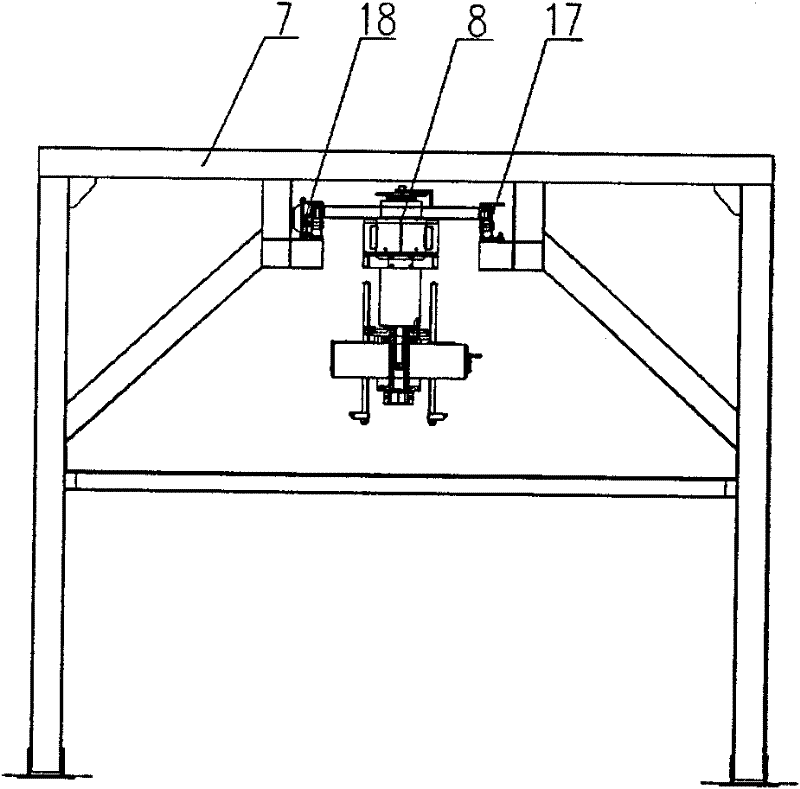

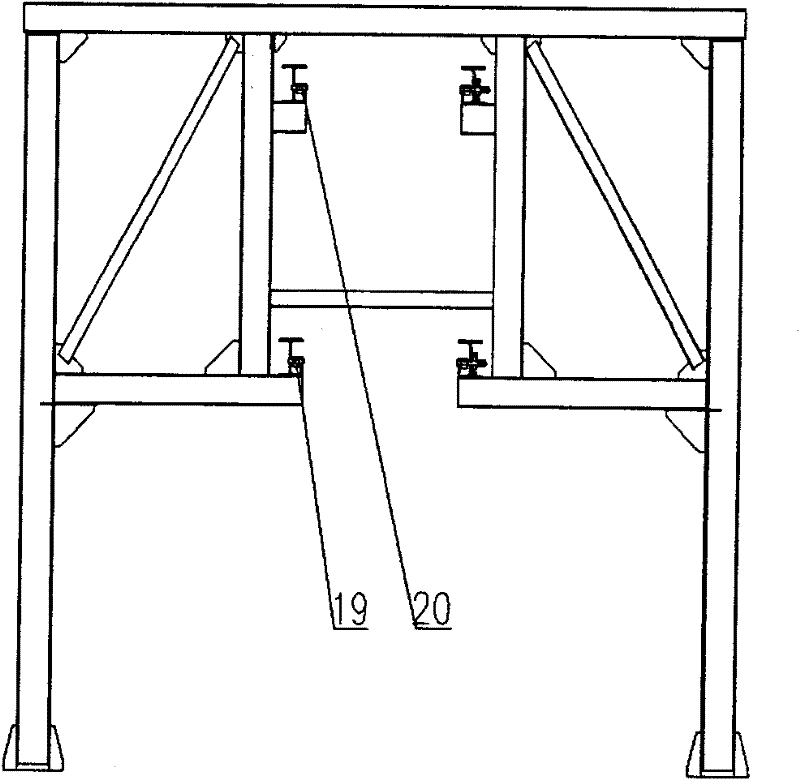

[0024] Such as figure 1 As shown, the double-dot dash line indicates the conveying line body, and the direction of the arrow indicates the conveying direction of the line body. The lower layer of the entire line body is used to transport the trolley and the workpiece with load, and the empty trolley on the upper layer returns to form a circular conveying system. The steel structure section of the single-layer roller conveyor line is as follows: figure 2 As shown, the steel structure of the double-layer roller conveyor line is as follows image 3 As shown, the connection between the single layer and the double layer is connected by a lifting system, and the top view of the lifting system is as follows Figure 5 As shown, the lifting system is composed of a steel structure and a screw lift 5, and the specific details will be described below.

[0025] The heavy-duty roller frame is installed on the gantry frame, and the trolley carrying the bogie suspension device is transport...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com