Automatic ring cutting device for glass tube

A glass tube, automatic technology, applied in the direction of glass cutting device, glass production, glass manufacturing equipment, etc., can solve the problems of irregular cutting edge shape, cutting error waste, etc., and achieve the goal of improving regularity, increasing yield and reducing waste Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

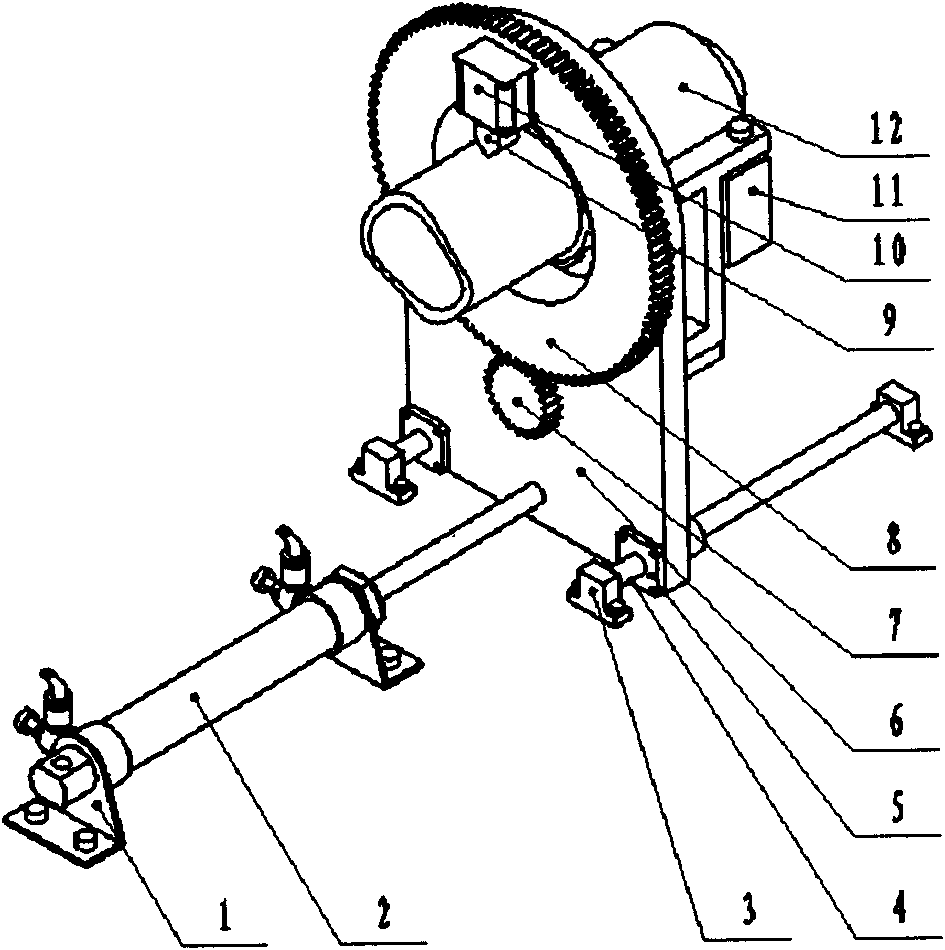

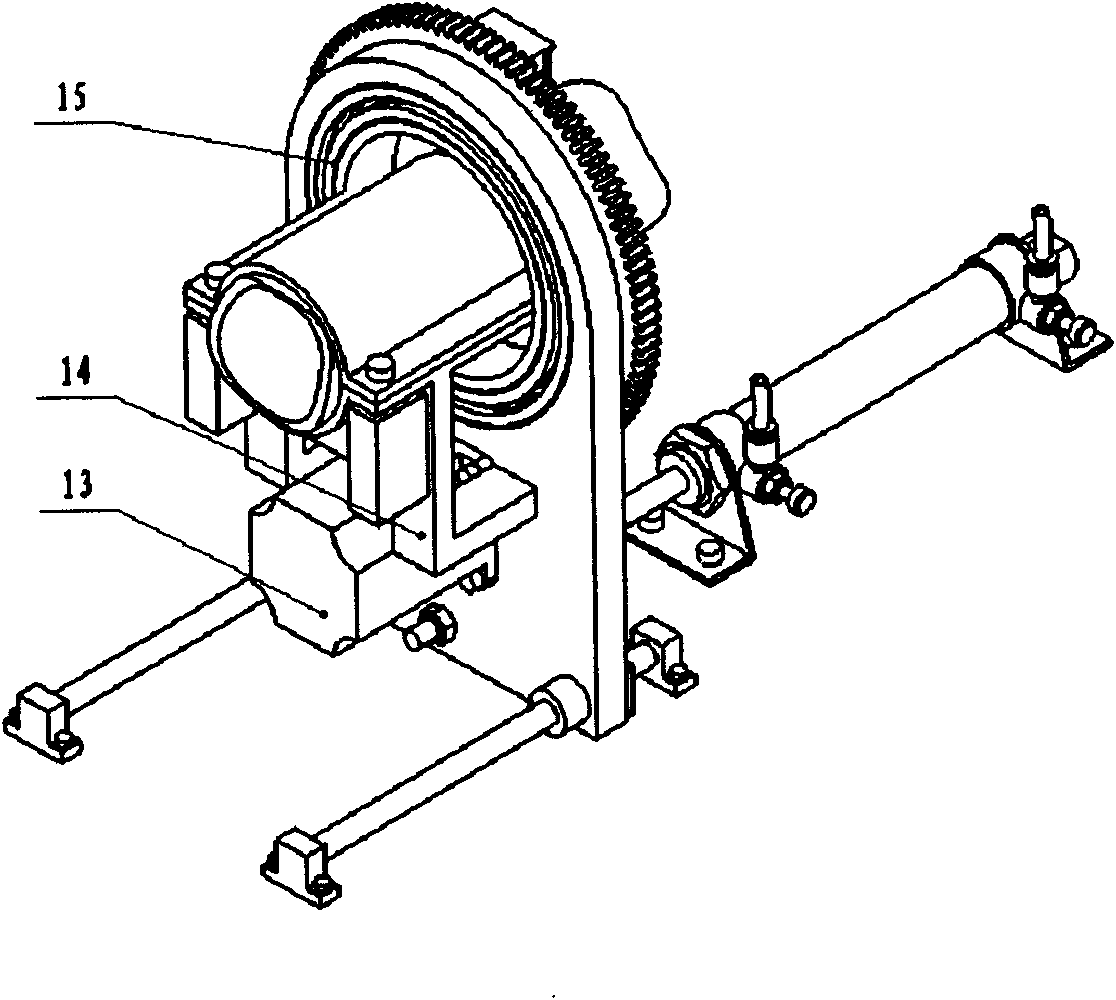

[0014] Embodiment: A glass tube automatic circular cutting device, consisting of a cylinder base 1, a cylinder 2, a guide rail base 3, a guide rail 4, a linear bearing 5, a bracket 6, a small gear 7, a large gear 8, a glass cutter 9, an electromagnet I10, Composed of electromagnet II11, arc-shaped pressing plate 12, stepper motor 13, lower bracket 14, and bearing 15, it is characterized in that two parallel guide rails 4 are installed on the base of the glass tube production line through guide rail base 3, and two linear bearings 5 It is fixedly installed on the bracket 6 and is in dynamic cooperation with the guide rail 4; the cylinder 2 is installed on the base of the glass tube production line through the cylinder base 1, the piston of the cylinder 2 is installed on the bracket 6, and the stepping motor 13 is installed on the bracket 6. The pinion 7 is installed on the output shaft of the stepping motor 13, the bull gear 8 is installed on the bracket 6 through the bearing 15...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com