Method for preparing castor oil-based polysiloxane polyol

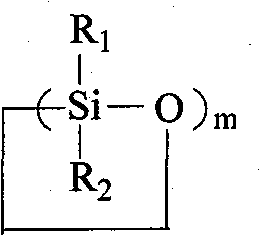

A technology based on polysiloxane and castor oil, which is applied in the field of preparation of polysiloxane polyols as intermediates of polymer materials, and can solve problems such as poor hydrolysis resistance, high cost, and low reactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

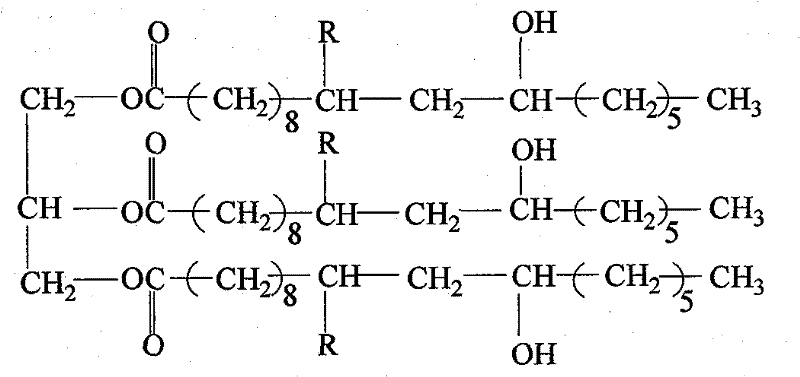

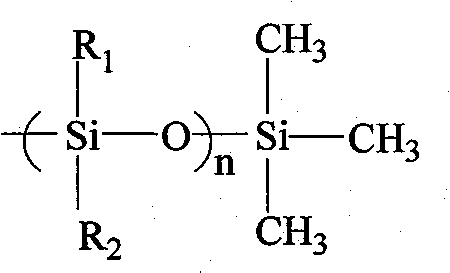

[0019] Add 198g of castor oil above into a 500mL three-necked flask, and then add 87.8g of pentamethyldisiloxane, add 0.8mL of chloroplatinic acid solution when the temperature rises to 80°C, continue to heat up to 100°C and react at 100°C for 5h. The unreacted pentamethyldisiloxane was distilled off under reduced pressure to obtain 272.3 g of castor oil hydrosilylation product.

[0020] 272.3g castor oil hydrosilylation product and 467g octamethylcyclotetrasiloxane (D 4 ) into a dry 1000mL three-necked flask equipped with a thermometer, a condenser and stirring, then added 3.62g of concentrated sulfuric acid, and reacted at 45°C for 48h; the product was washed with deionized water and distilled under reduced pressure to obtain 598g of castor oil-based polymer Silicone polyol.

Embodiment 2

[0022] Add the above-mentioned 198g of castor oil into a 500mL three-necked flask, then add 87.8g of pentamethyldisiloxane, add 0.8mL of chloroplatinic acid solution when the temperature rises to 80°C, continue to heat up to 100°C and react at 100°C for 5h, after reducing The unreacted pentamethyldisiloxane was distilled off under pressure to obtain 272.3 g of castor oil hydrosilylation product.

[0023] With 272.3g castor oil hydrosilylation product and 700g octamethylcyclotetrasiloxane (D 4 ) into a dry 1000mL three-necked flask equipped with a thermometer, condenser and stirring, then added 4.8g of concentrated sulfuric acid, and reacted at 45°C for 60h; the product was washed with deionized water, and 885g of castor oil-based poly Silicone polyol.

Embodiment 3

[0025] Add the above 198g castor oil into a 500mL three-necked flask, then add 87.8g pentamethyldisiloxane, add 0.8mL silicene complex platinum catalyst when the temperature rises to 80°C, continue to heat up to 100°C and react at 100°C for 5h. , The pentamethyldisiloxane that did not participate in the reaction was removed by distillation under reduced pressure to obtain 272.3 g of castor oil hydrosilylation product.

[0026] With 272.3g castor oil hydrosilylation product and 1300g octamethylcyclotetrasiloxane (D 4 ) into a dry 2000mL three-necked flask equipped with a thermometer, a condenser and stirring, then added 7.7g of concentrated sulfuric acid, and reacted at 45°C for 72h; the product was washed with deionized water, and 1380g of castor oil-based polymer was obtained by distillation under reduced pressure. Silicone polyol.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com