Method for extracting tea seed oil by water with microwave pretreatment

A tea seed oil and pretreatment technology, applied in the direction of fat oil/fat production, fat generation, etc., can solve the problems of low oil yield and difficult application in low temperature storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Weigh 100kg of dehulled tea seed kernels containing 47% oil, add 1.5kg of tea seed oil as an oil-inducing agent, mix thoroughly and grind to 60-80 mesh, heat the crushed material to 55°C by microwave irradiation, and Add 250L of 60°C hot water at a ratio of 2.5:1 to adjust the slurry, then stir and leach at a constant temperature of 60°C and 40r / min for 35min, and then vacuum-dry the clear oil after centrifugation to obtain 46.56kg of tea seed oil, and calculate the oil yield for:

[0022] 46.56kg-1.5kg=45.06kg / 47kgx100%=95.87%

Embodiment 2

[0024] Weigh 100kg of shelled tea seed kernels containing 50.6% oil, add 7.5kg of tea seed oil as an oil-inducing agent, pulverize to 60-80 mesh, heat the pulverized material to 85°C by microwave irradiation, add 85°C heat at a ratio of 10.5:1 Mix 1050L of water, stir and leach for 150min at a constant temperature under the conditions of 85°C and 180r / min, and vacuum-dry the clear oil after centrifugation to obtain 56.06kg of tea seed oil. The calculated oil rate is:

[0025] 56.06kg-7.5kg=48.56kg / 50.6kgx100%=95.97%

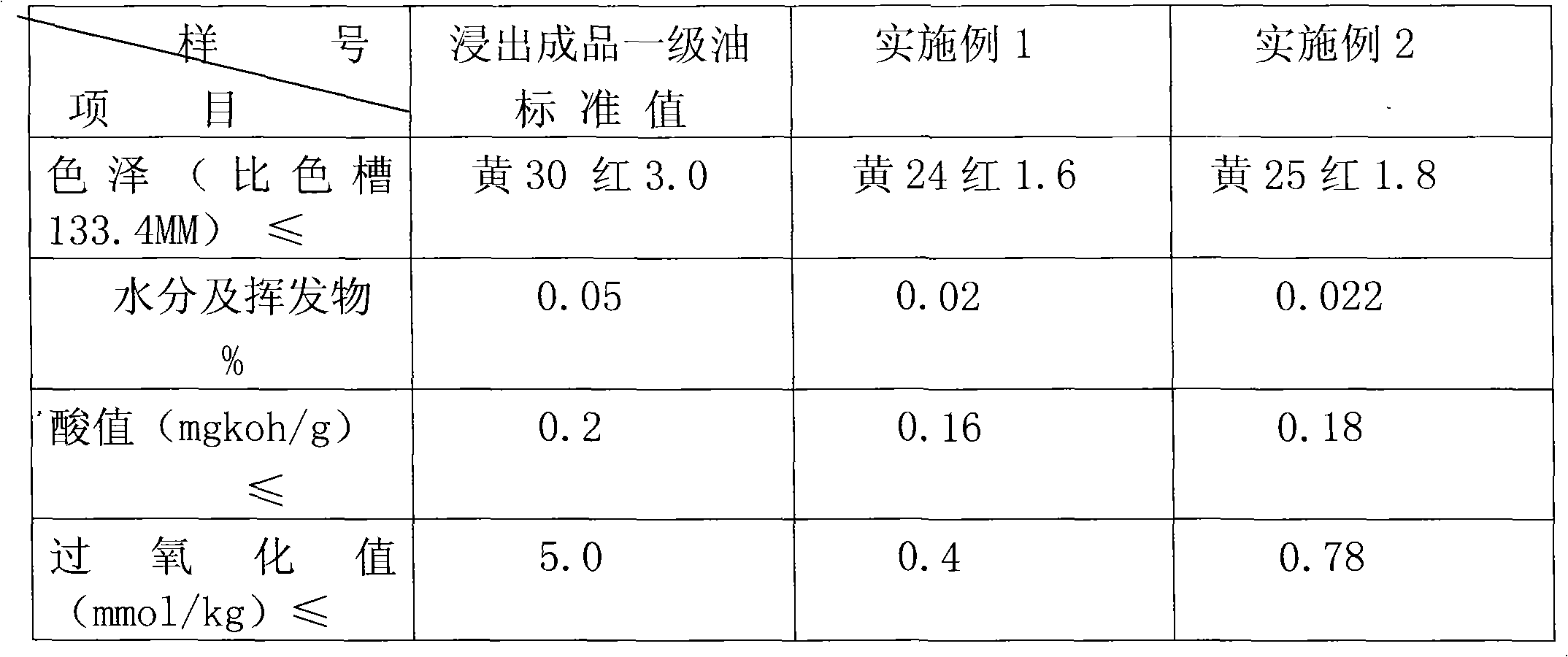

[0026] After testing, the main indicators of Examples 1 and 2 have exceeded the national standard for leaching first-grade finished tea seed oil, and the specific data are as shown in Table 1:

[0027] Table 1 Comparison table of the national standard value of the first-grade leached tea seed oil and the main indicators of Examples 1 and 2

[0028]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com