Production method of high magnetic induction grain-oriented silicon steel strip

A technology of high magnetic induction orientation and production method, applied in the direction of coating, furnace type, furnace, etc., can solve the problem that high magnetic induction oriented silicon steel products cannot be obtained, and achieve high quality, precise control of production process, and improved quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

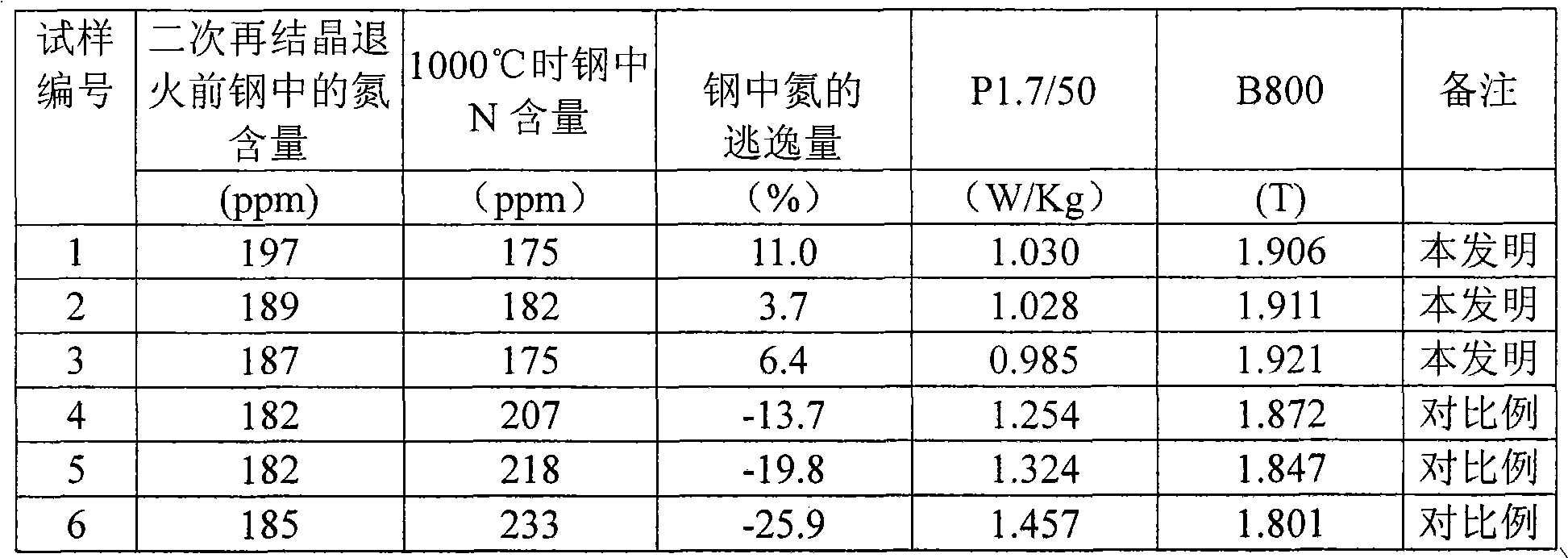

Embodiment and comparative example 1

[0028] A production method for rolling a 210mm thick continuous casting slab into a high magnetic induction oriented silicon steel strip comprises the following steps:

[0029] 1) In the molten steel continuous casting process, cast a continuous casting slab with a thickness of 210 mm, and control its chemical composition in terms of weight percentage: C: 0.058, Si: 3.15, Al sol : 0.030, N: 0.008, Cu: 0.080, Sn: 0.053, Mn: 0.100, S: 0.010, Cr: 0.020, P: 0.010, Ti: 0.002, and the rest are Fe and inevitable inclusions.

[0030] 2) The obtained continuous casting slab is heated to 1180° C. for hot rolling, and rolled into a hot-rolled steel strip with a thickness of 2.2 mm. The coiling temperature of the hot-rolled steel strip is controlled at 550° C.

[0031] 3) Two-stage annealing and normalization processes are used to process the obtained hot-rolled steel strip. The heating temperature of the first stage annealing and normalization process is 1120 ° C, and the holding time is...

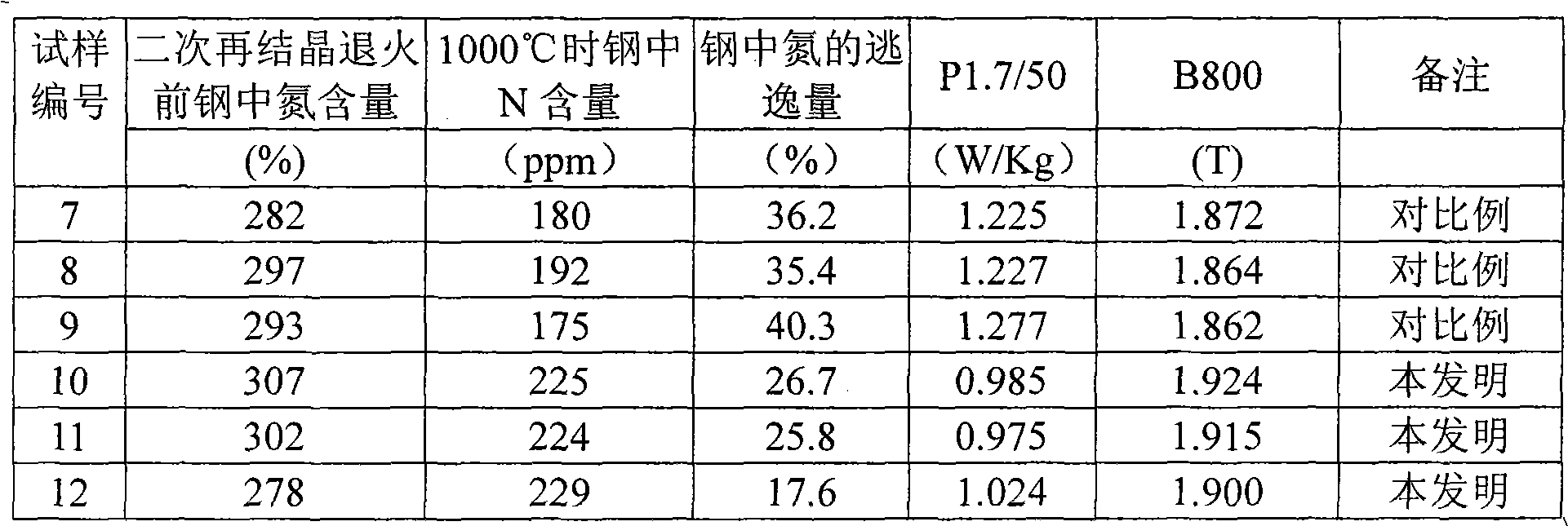

Embodiment and comparative example 2

[0042] The production method of rolling a 230mm thick continuous casting slab into a high magnetic induction oriented silicon steel strip comprises the following steps:

[0043] 1) In the molten steel continuous casting process, cast a continuous casting slab with a thickness of 230 mm, and control its chemical composition in terms of weight percentage: C: 0.060, Si: 3.19, Al sol : 0.032, N: 0.005, Cu: 0.050, Sn: 0.100, Mn: 0.070, S: 0.003, Cr: 0.100, P: 0.020, Ti: 0.002, and the rest are Fe and inevitable inclusions.

[0044] 2) The obtained continuous casting slab is heated to 1150° C. for hot rolling, and rolled into a hot-rolled steel strip with a thickness of 2.2 mm. The coiling temperature of the hot-rolled steel strip is controlled at 550° C.

[0045] 3) Two-stage annealing and normalization processes are used to process the obtained hot-rolled steel strip. The heating temperature of the first stage annealing and normalization process is 1100 ° C, and the holding time i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com