Flowing water resistor and device for carrying out on-line insulation detection by using the same

A technology of water resistors and resistors, applied in the direction of resistors, non-adjustable metal resistors, non-adjustable liquid resistors, etc., can solve the problems of steel ball surface loss, inability to judge, surface insulation film wear, etc., to achieve simplification Equipment, effective space saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the object, technical solution and advantages of the present invention clearer, the flowing water resistance of the present invention and the device for online withstand voltage detection using the flowing water resistance of the present invention will be further described in detail with reference to the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, and are not intended to limit the present invention.

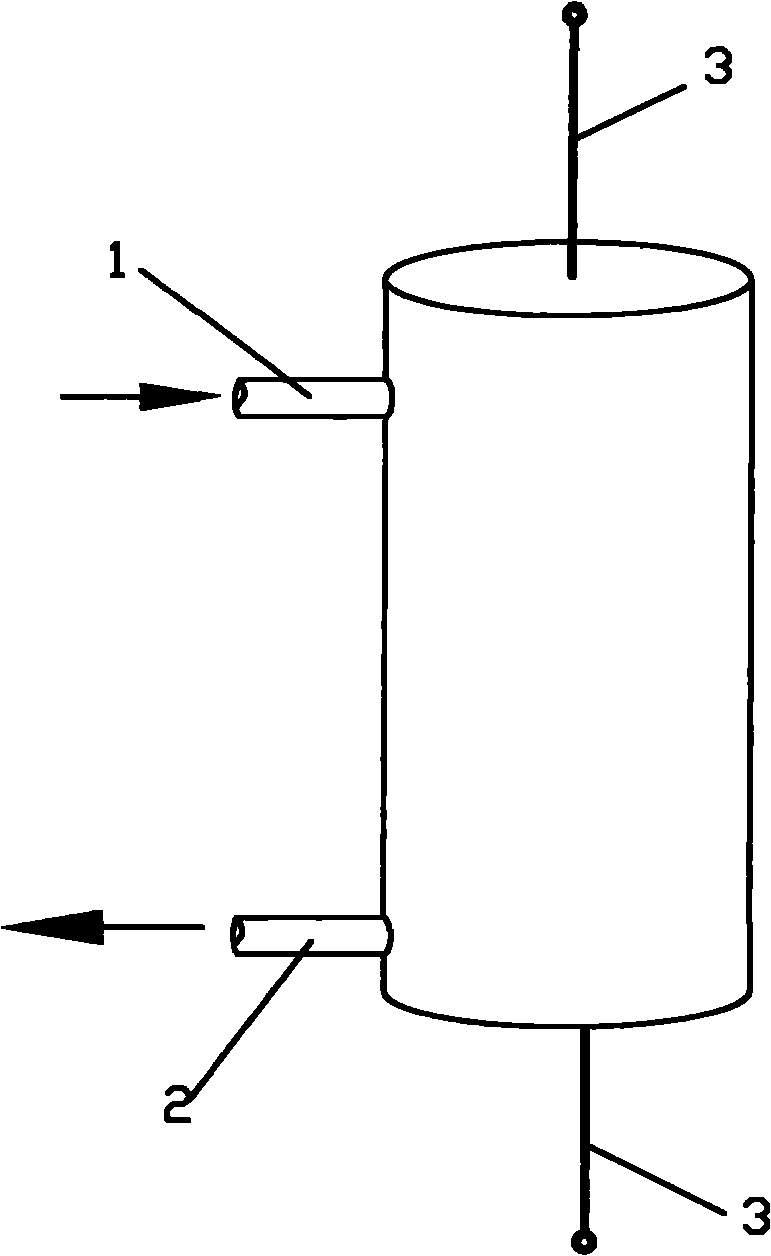

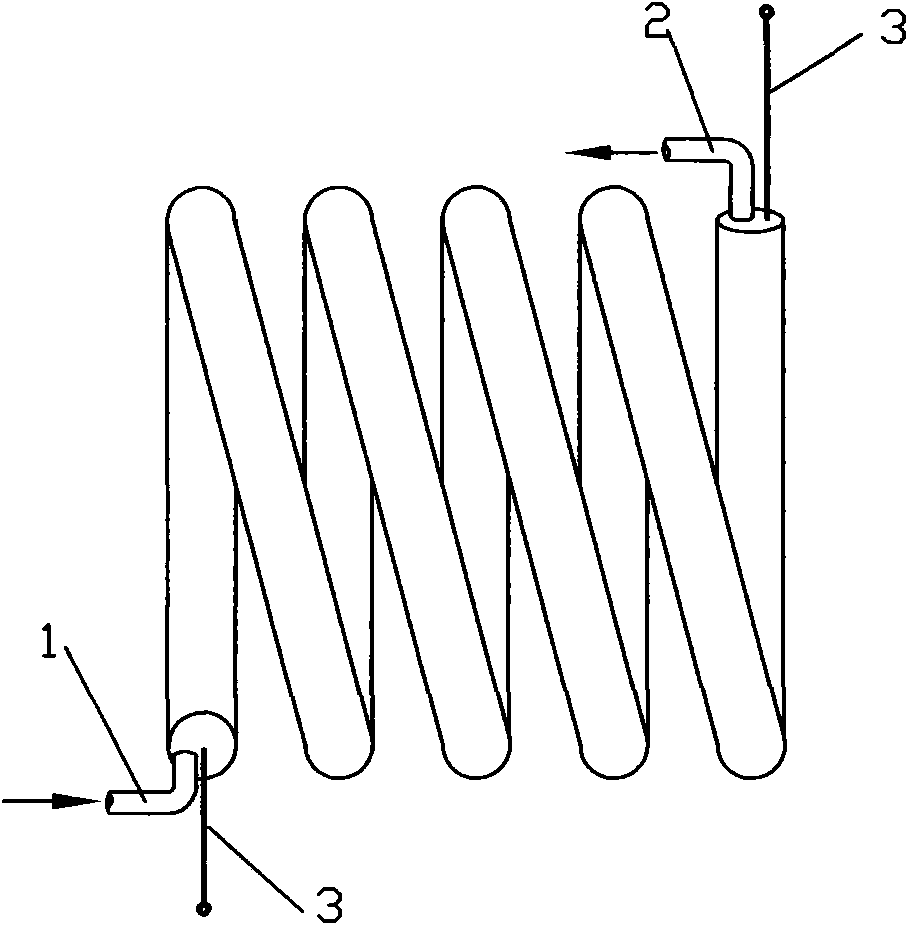

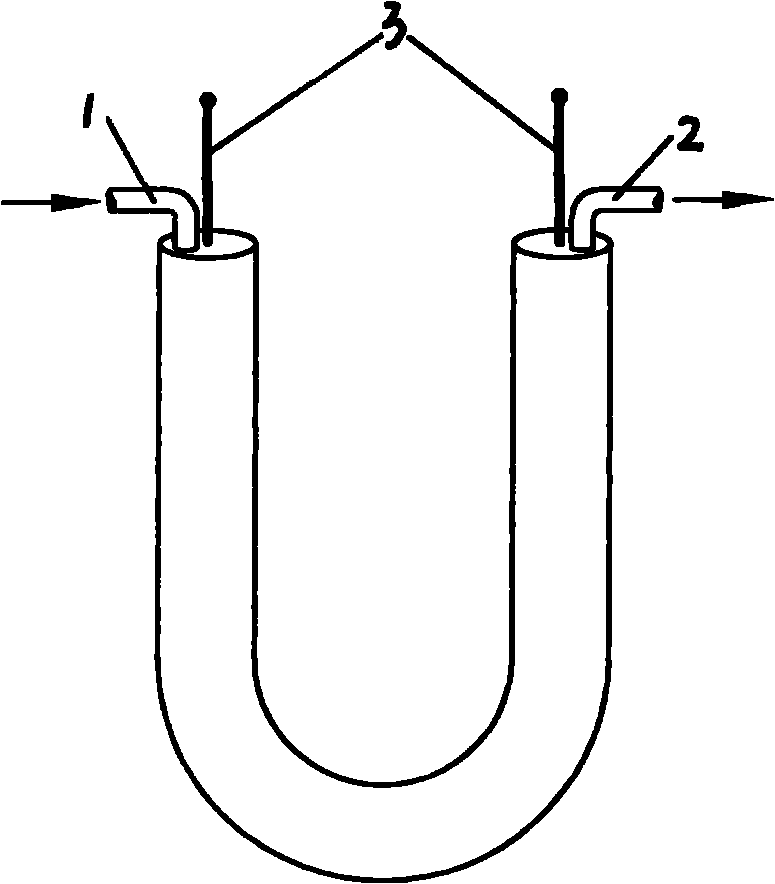

[0030] Firstly, the flowing water resistor of the present invention and its obtaining method will be described.

[0031] Generally, the resistors used in the circuit appear in the form of solid-state hardware regardless of their resistance value. Water is usually a solution of substances such as acids, alkalis, and salts (as are other liquids with similar properties); water is a colorless, odorless, transparent liquid at normal temperature and pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com