Driving printed circuit board and liquid crystal display

A technology for printed circuit boards and liquid crystal displays, applied to printed circuit parts, printed circuits connected with non-printed electrical components, instruments, etc. Low-level problems, to achieve the effect of simplifying the assembly process, improving the yield rate, and simplifying the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Hereinafter, the present invention will be further described in detail through specific embodiments in conjunction with the accompanying drawings.

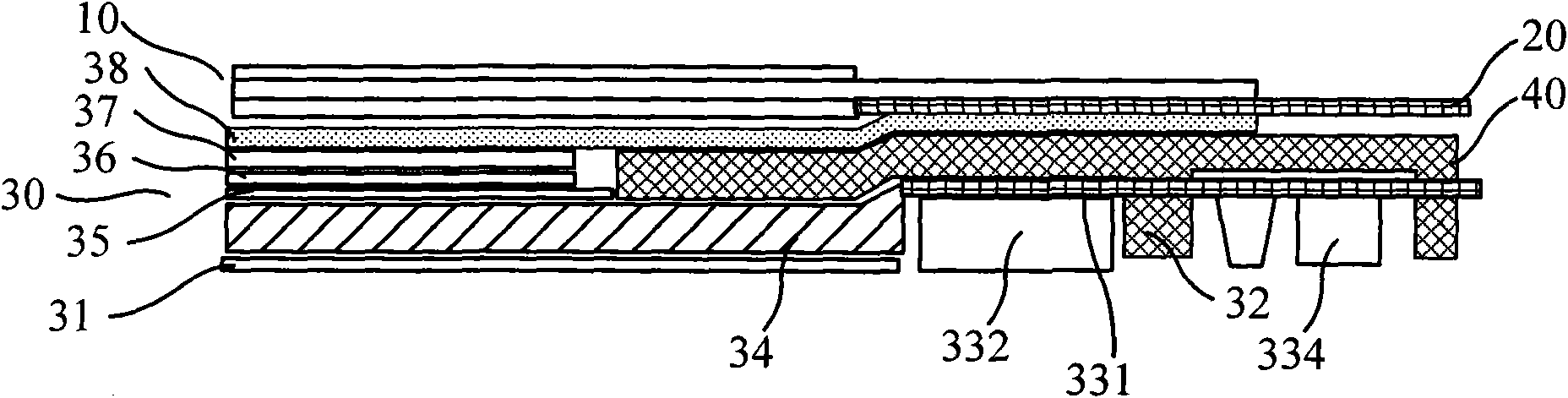

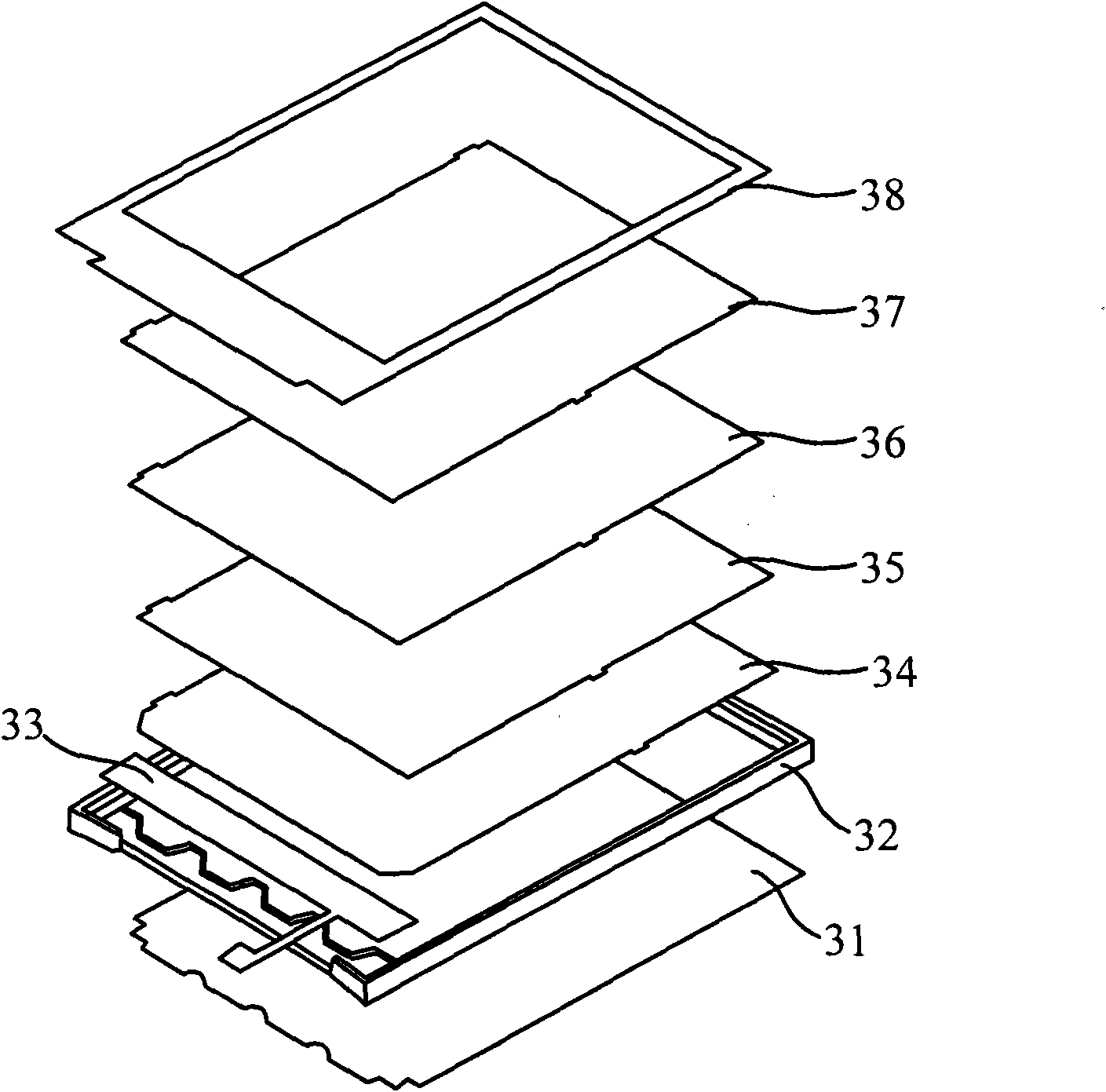

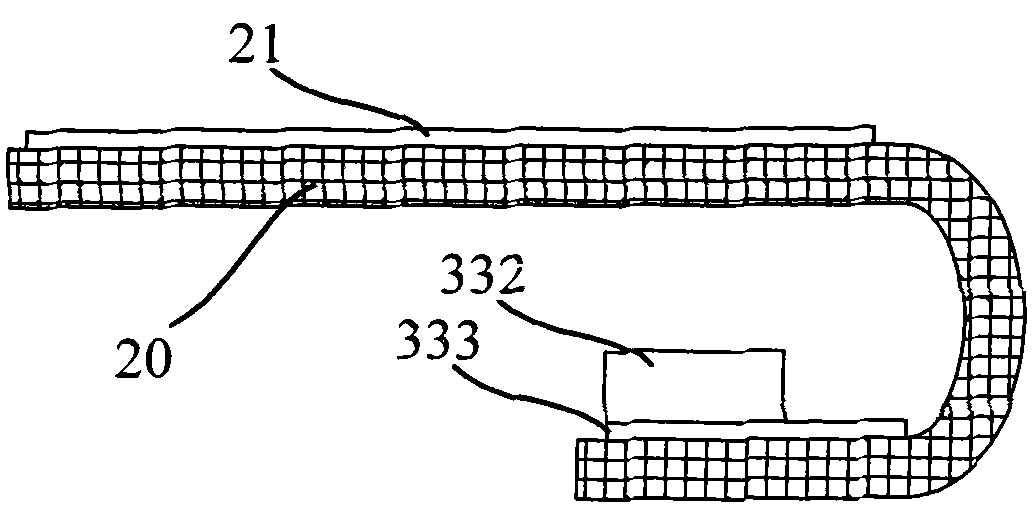

[0023] Drive printed circuit board embodiment

[0024] image 3 It is a schematic structural diagram of an embodiment of a driving printed circuit board of the present invention. The driving printed circuit board of this embodiment is applied to a liquid crystal display. In this embodiment, the driving printed circuit board 20 is specifically made of a flexible printed circuit board (Flexible Printed Circuit Board; hereinafter referred to as FPCB), and a liquid crystal panel driving circuit 21 and a backlight module driving are arranged on the driving printed circuit board 20. The circuit 333; the backlight module driving circuit 333 is used to mount the light source 332; when the driving printed circuit board 20 is in the assembled state, the part where the backlight module driving circuit 333 is arranged is bent into the backl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com