Electrode for lithium rechargeable battery and lithium rechargeable battery comprising the electrode

A lithium secondary battery and electrode technology, applied in the field of electrodes for lithium secondary batteries, can solve problems such as difficulty in applying large-scale production processes, and achieve improved charge-discharge cycle characteristics and reliability, excellent charge-discharge cycle characteristics, and suppression of aggregation. The effect of electrical deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

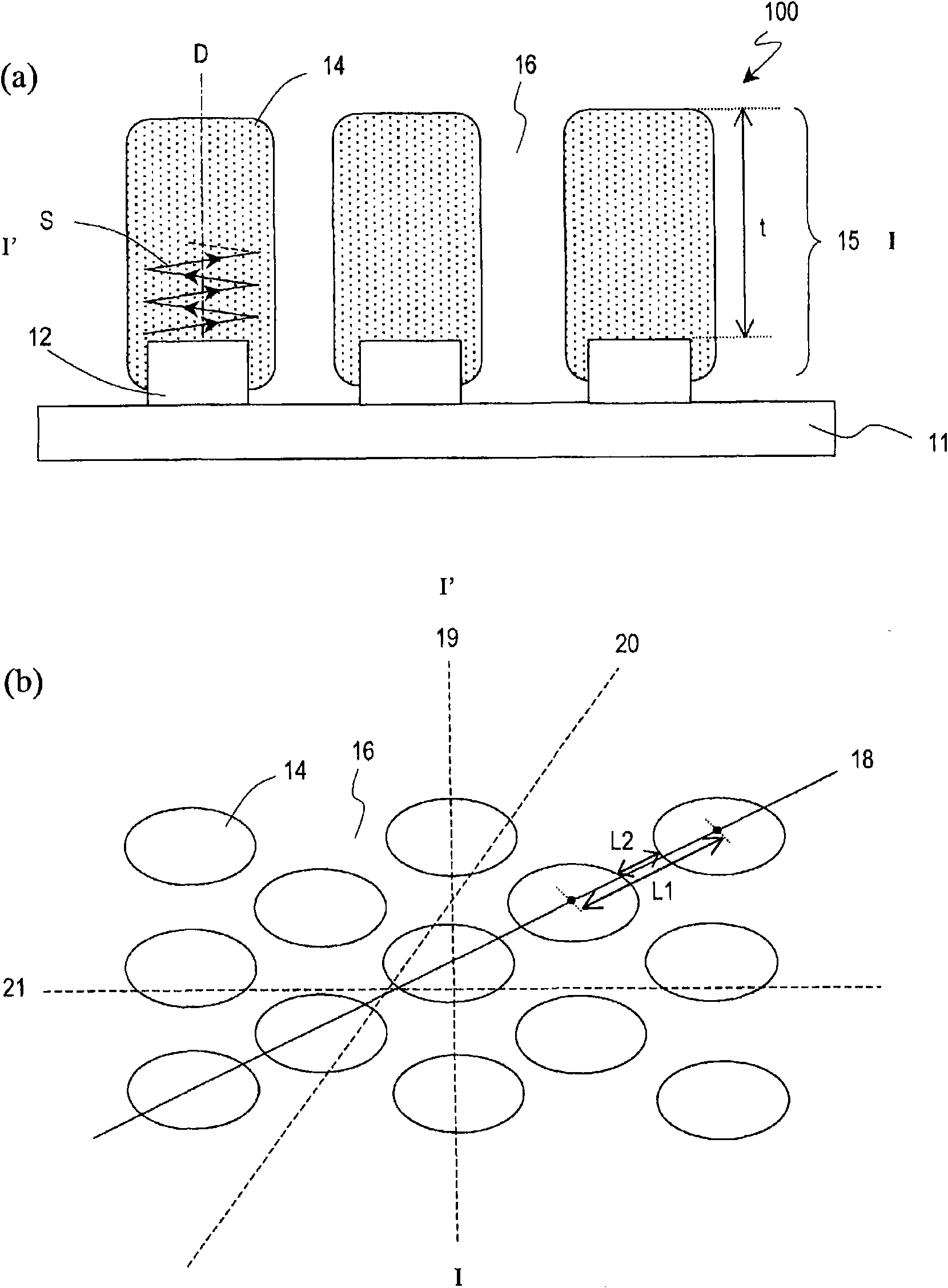

[0062] Refer to the attached Figure 1 A first embodiment of the electrode for a lithium secondary battery of the present invention will be described. The electrode of this embodiment can be applied to either a negative electrode or a positive electrode of a lithium secondary battery, and is preferably used as a negative electrode for a lithium secondary battery.

[0063] First, refer to figure 1 (a) and figure 1 (b). figure 1 (a) is a schematic sectional view of the electrode of this embodiment, figure 1 (b) is a plan view of the active material layer in a state where lithium is not occluded. in addition, figure 1 (a) means along figure 1 (b) I-I' line cross-section of the active material layer.

[0064] The electrode 100 includes: a current collector 11 having a plurality of protrusions 12 on the surface; and an active material layer 15 formed on the surface of the current collector 11 . The plurality of protrusions 12 are regularly arranged at intervals on the surfa...

Embodiment and comparative example -1

[0154] Here, electrodes 1 to 11 were produced as examples, and electrode C1 was produced as a comparative example, and the measurement of the minimum linear void ratio in each active material layer and the deformation (elongation) of the electrodes caused by constant current charging were performed. Evaluation. Furthermore, the sample batteries a and b using the electrode 8 and the electrode 10 were produced, and a charge-discharge cycle test was performed, so the method and results thereof will be described.

[0155] (i) Electrode fabrication method

[0156] (i-1) Electrode 1

[0157]

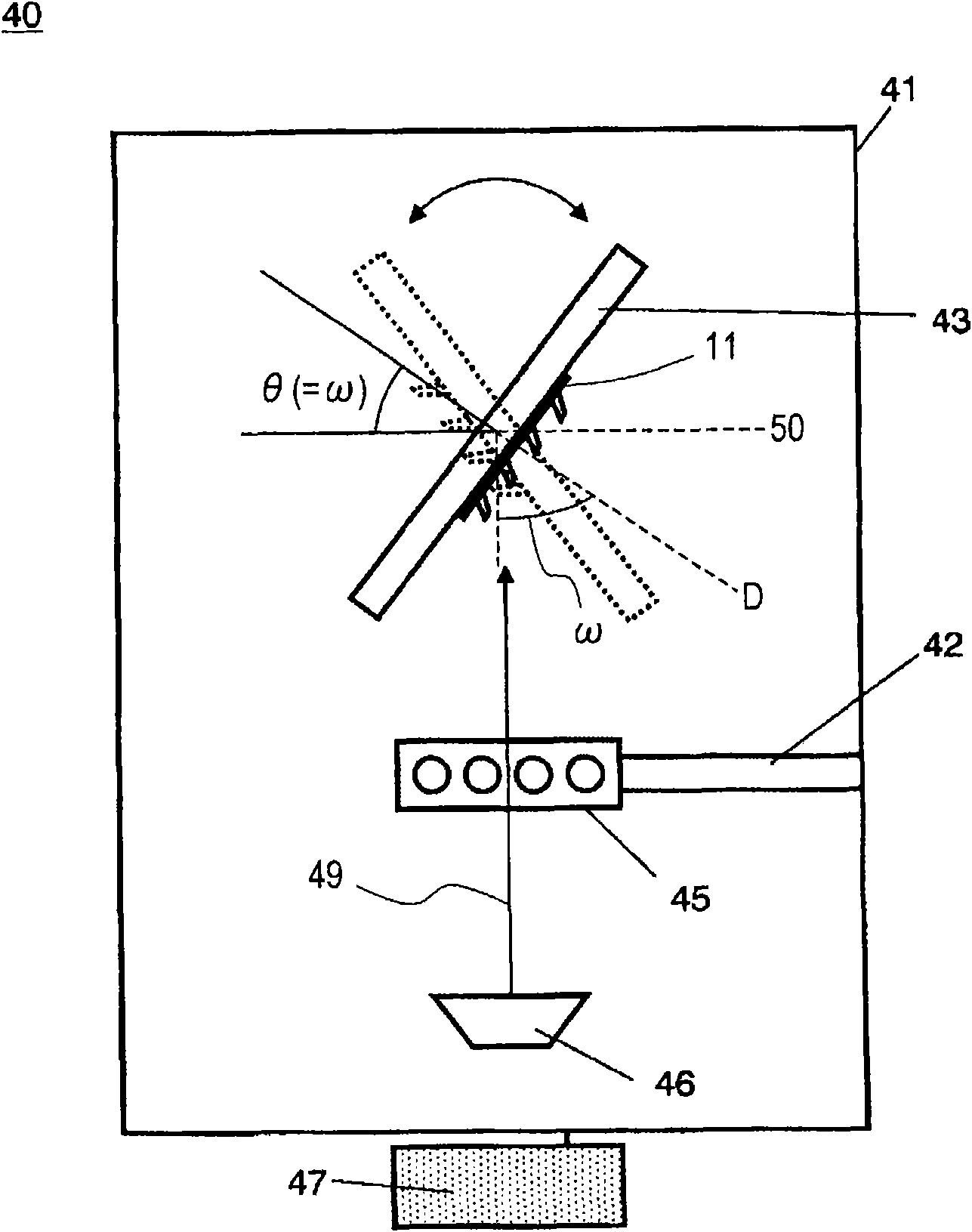

[0158] First, a method for producing a current collector used in the electrode 1 will be described. Figure 8 (a) to (c) are cross-sectional process diagrams for explaining the production method of the current collector in this example.

[0159] like Figure 8 As shown in (a), both sides of a copper foil (HCL-02Z, manufactured by Hitachi Electric Cable Co., Ltd.) having a thickness of 27...

Embodiment and comparative example -2

[0219] Here, electrodes 12 to 16 were produced as an example, electrodes C2 and C3 were produced as a comparative example, and the measurement of the minimum linear void ratio in each active material layer and the evaluation of the electrode plate strength were performed. Furthermore, sample batteries each having the electrodes 12 to 16 and the electrodes C2 and C3 as negative electrodes were produced, and the presence or absence of electrode deformation due to charging and discharging was investigated, and the methods and results thereof will be described.

[0220] (i) Electrode fabrication method

[0221] (i-12) Electrode 12

[0222]

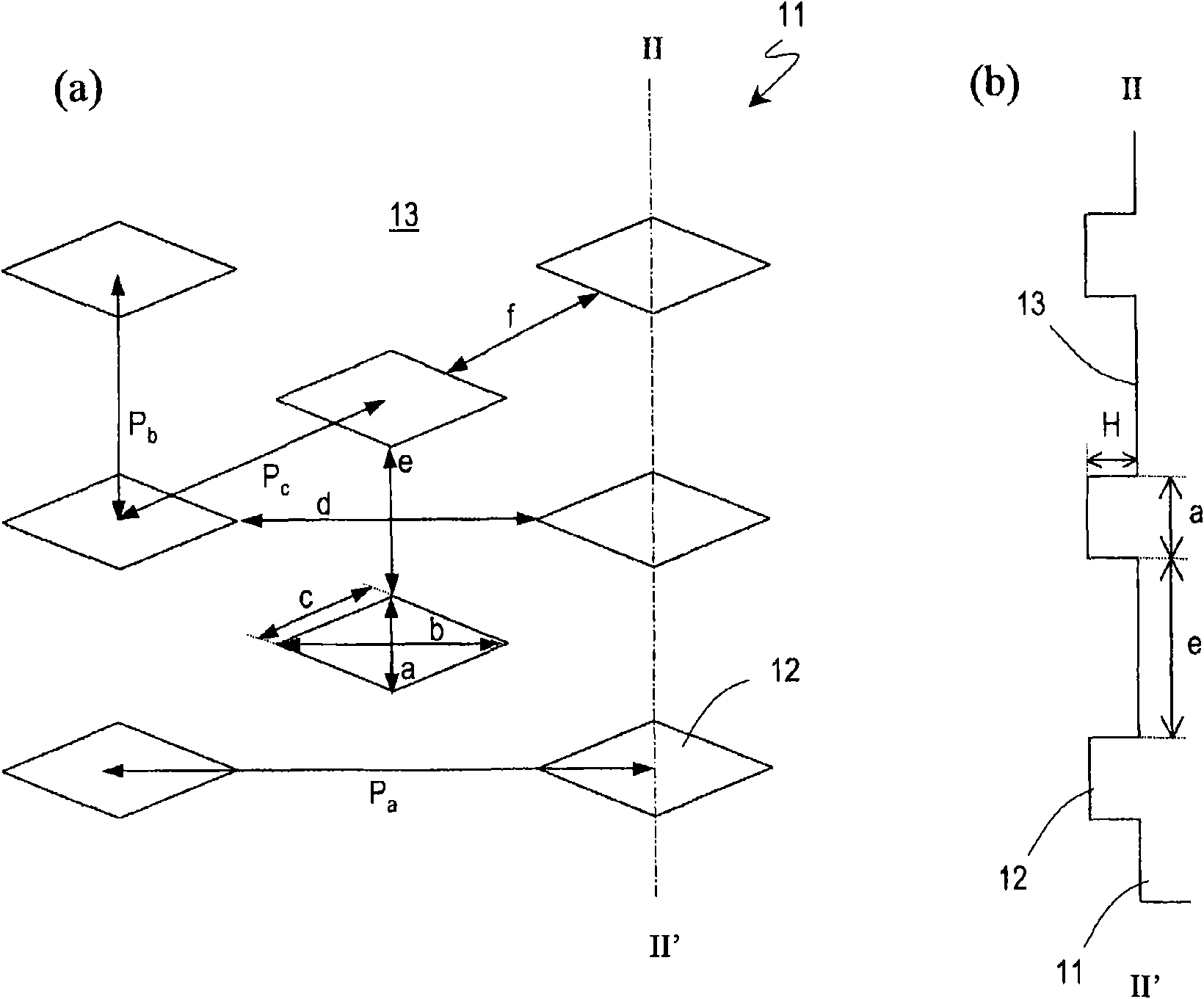

[0223] A rolled alloy copper foil (HCL-305 manufactured by Hitachi Electric Cable Co., Ltd.) with a thickness of 18 μm is cut into a size of 80 mm×15 mm, and one side is formed by plating Figure 13 A plurality of protrusions 12 are shown with a rhomboid upper face. Specifically, first, on the above-mentioned copper foil, by exposing and d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com