Heavy load salvage wave compensation system of super large floating crane

A floating crane and monitoring system technology, used in marine heavy industry, port heavy machinery, and deep sea salvage fields, can solve the problems of unstable, disordered and uncontrollable hulls

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

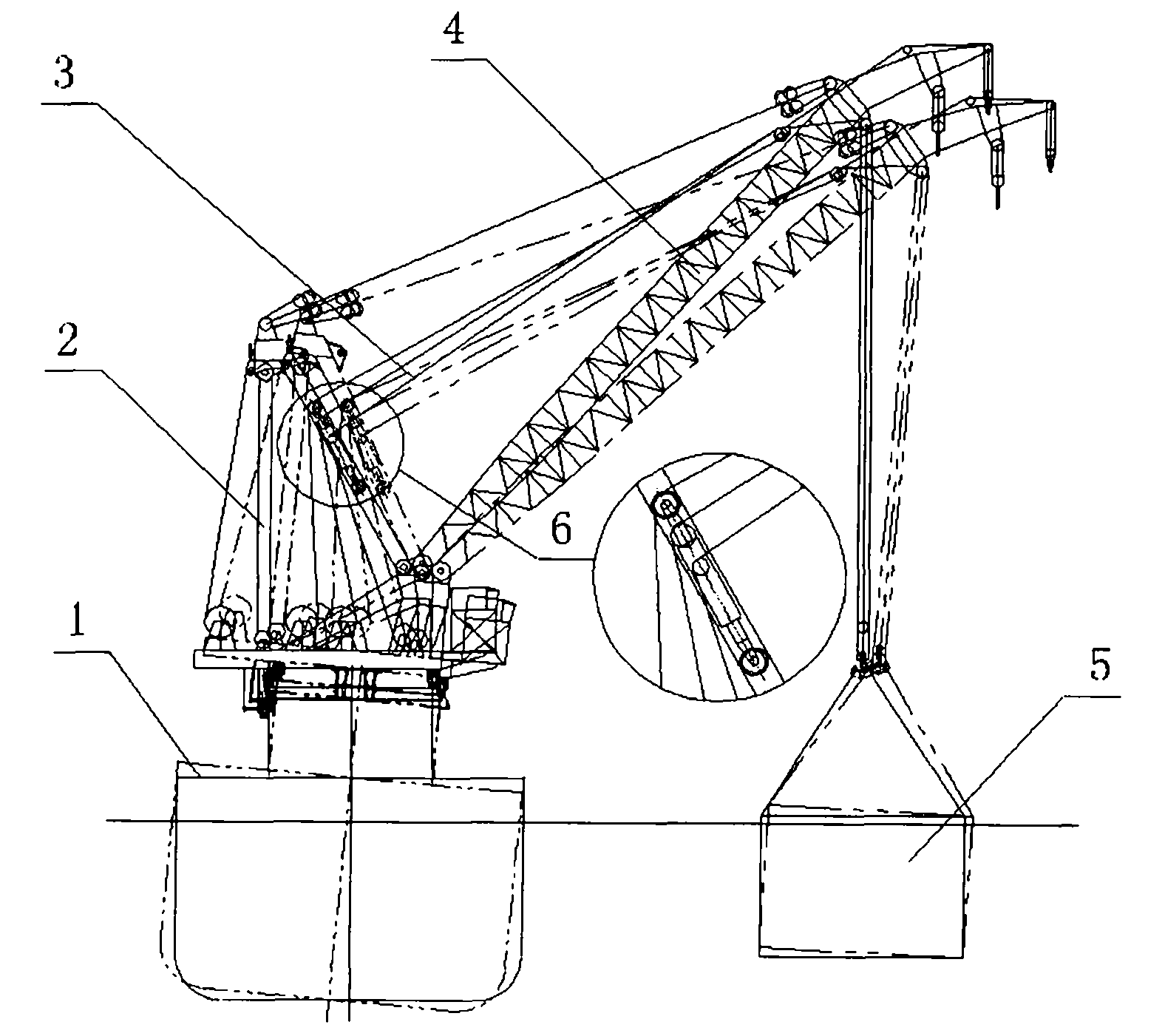

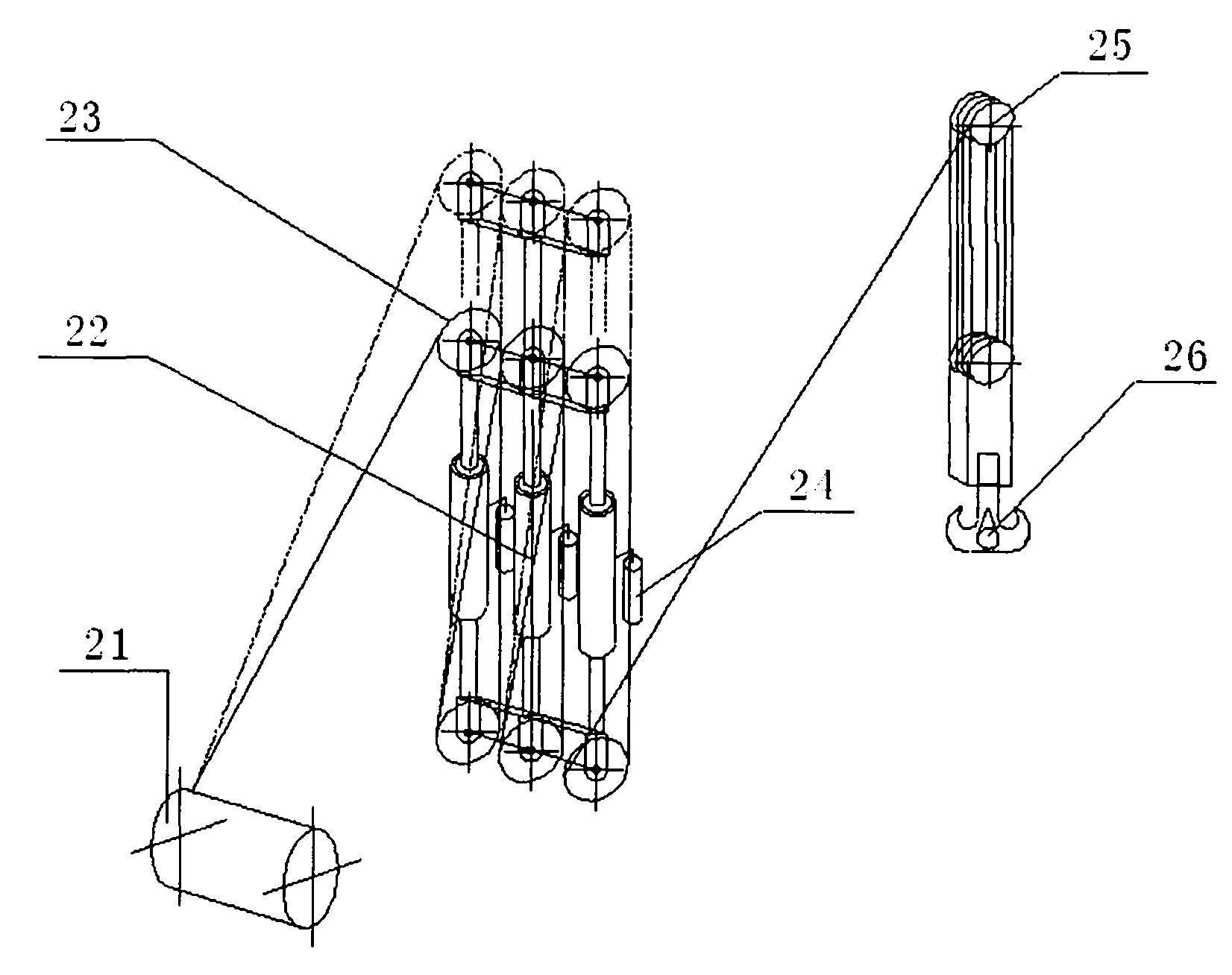

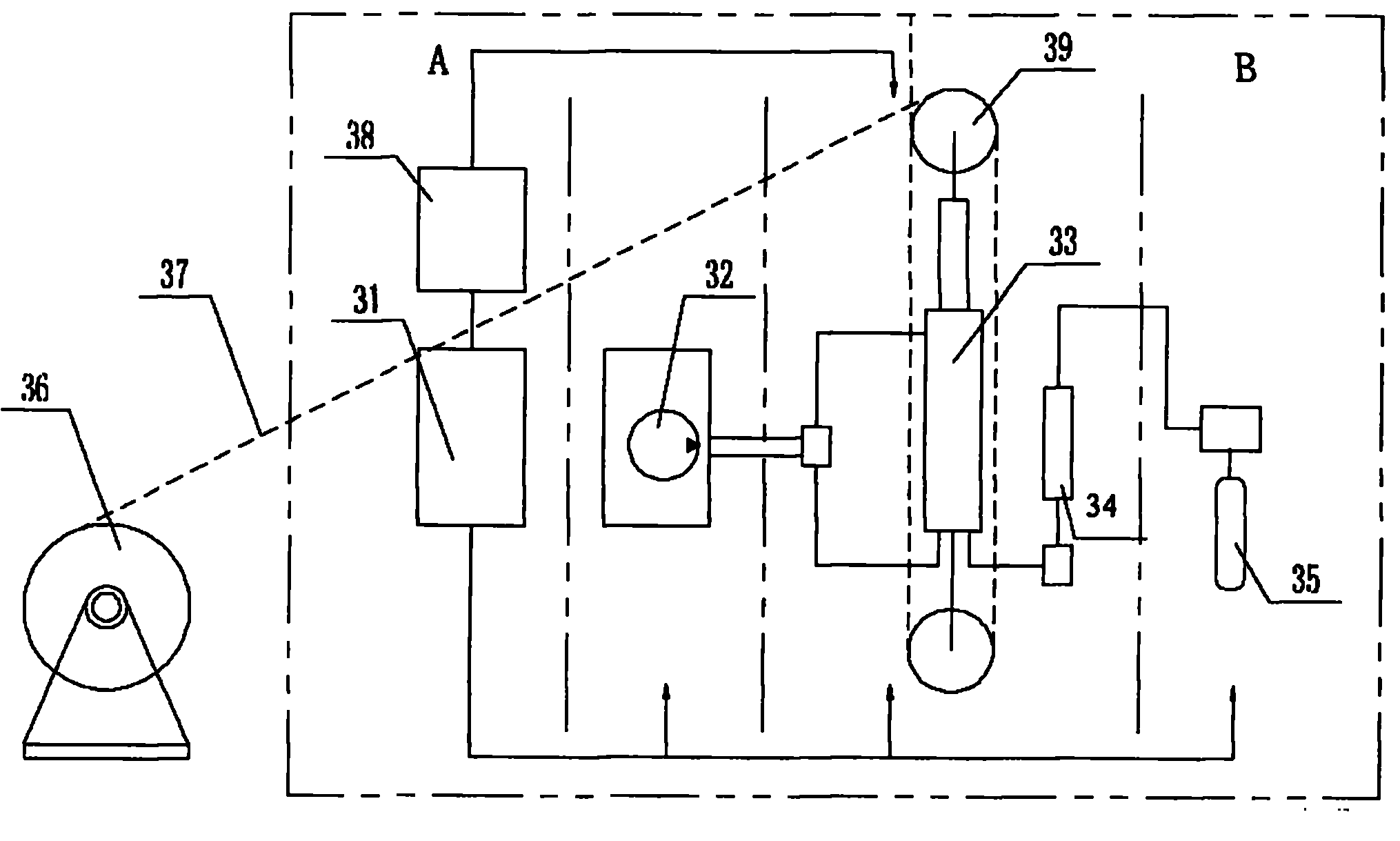

[0028] The specific implementation method is combined with the attached image 3 Further description of the heavy-duty floating crane of the present invention:

[0029] Monitoring sensors are arranged at various key positions such as the floating crane hull and the head of the floating crane jib, and the sensors transmit the detected signals to the monitoring system in real time;

[0030] First of all, when the floating crane lifts heavy objects, due to the swing of the floating crane hull due to the action of waves, the lifting wire rope will elongate and contract accordingly. At this time, the control system will process the signals collected by the sensors at each point through the PLC controller. And issue a command, the active compensation circuit A acts to control the extension of the piston rod of the hydraulic cylinder to absorb the excess hoisting wire rope, so that the hoisting wire rope is always in a tensioned state, and the weight remains balanced without swinging...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com