Method for refining trichlorosilane

A technology of trichlorosilane and refining method, applied in the direction of silicon, halogenated silanes, halogenated silicon compounds, etc., can solve the problems of changes in the purity of silicon tetrachloride, unstable quality, etc., and achieves half of the possibility and long-term cost reduction. half, large effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

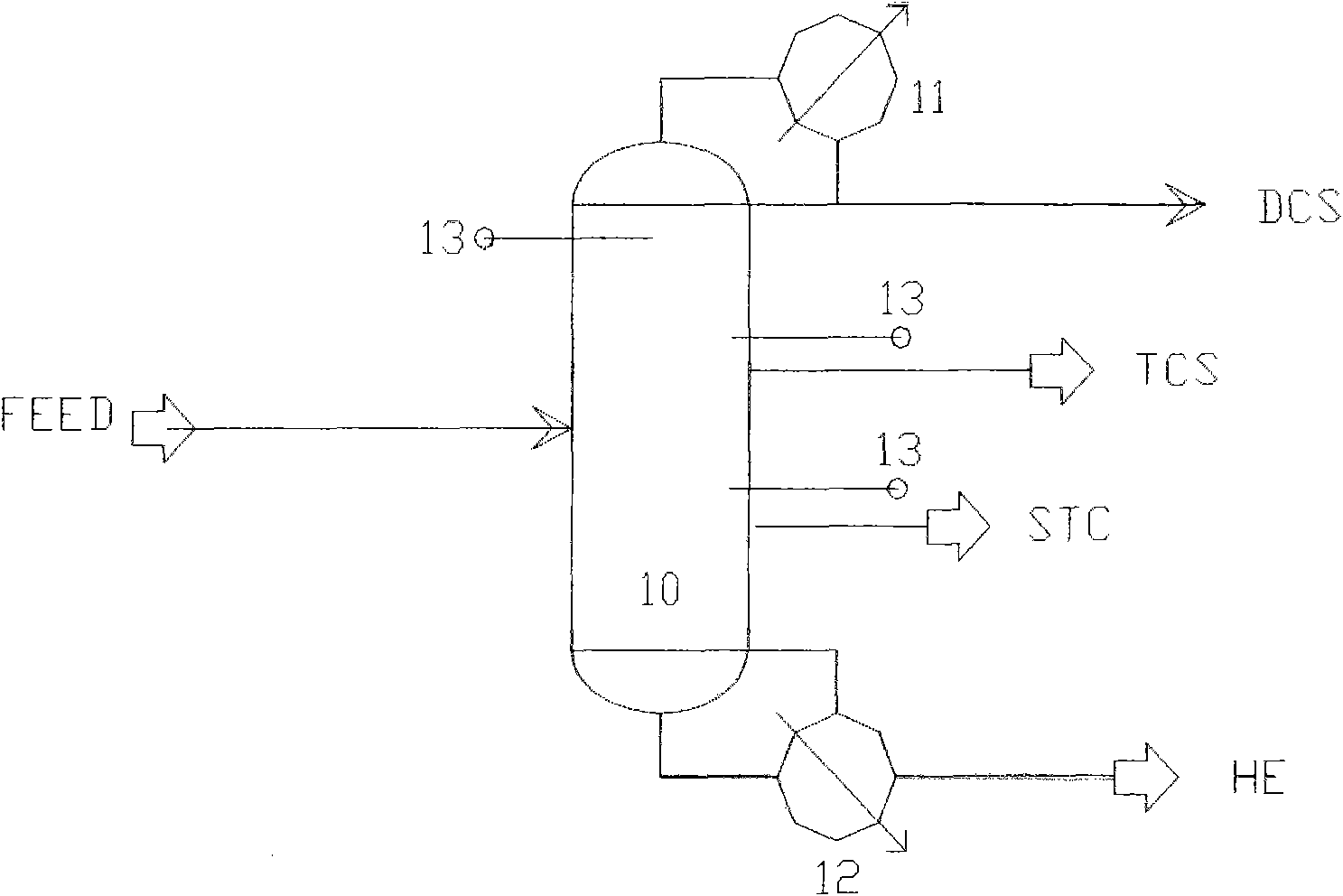

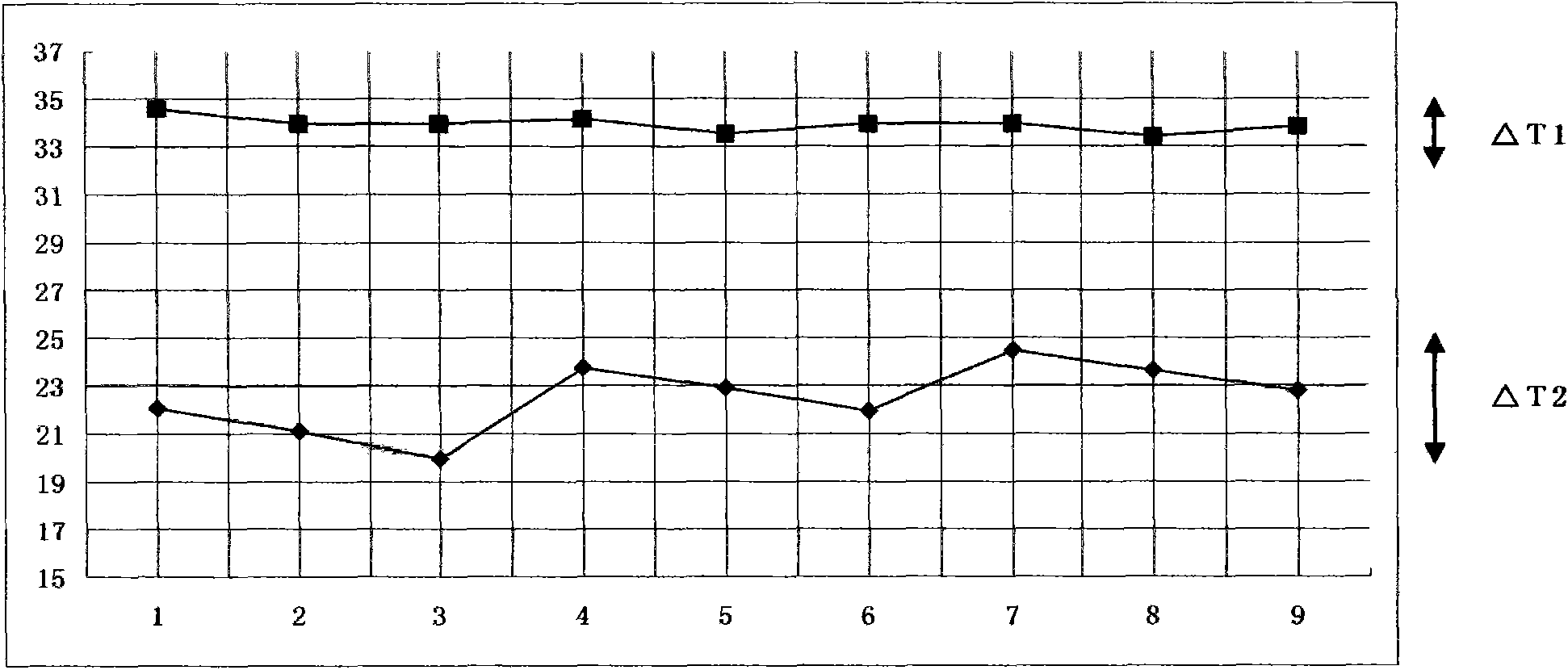

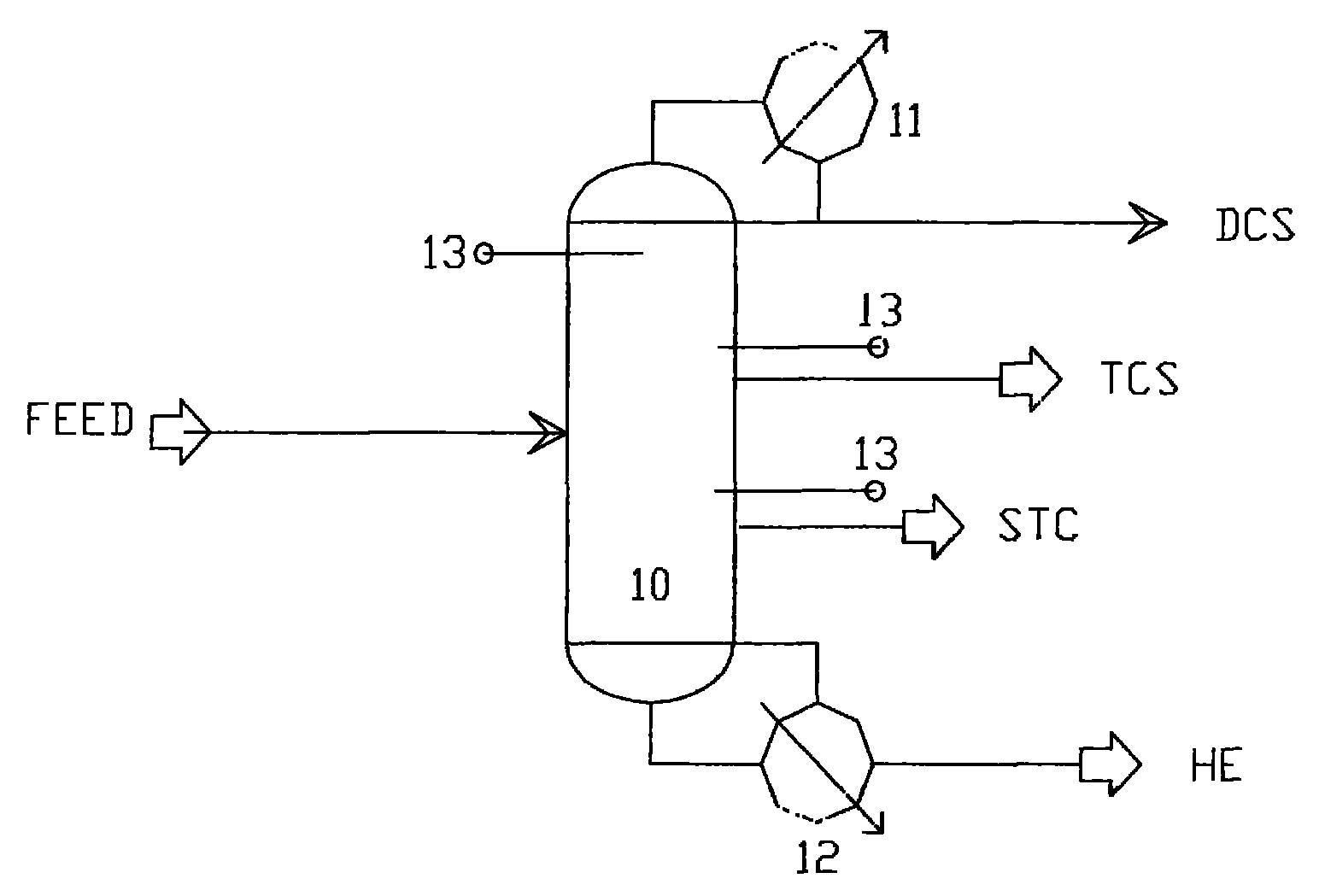

[0024] Such as figure 1 As shown, in this implementation, when polysilicon is manufactured according to the vapor phase deposition method, the gas discharged from the reduction furnace is a mixture of trichlorosilane, dichlorosilane and silicon tetrachloride, which is discharged from several reduction furnaces used The chlorosilane liquid obtained after cooling the gas is supplied to the middle stage of the fractionator 10 as a feed liquid. The objects recovered in the chlorosilane liquid are dichlorosilane, trichlorosilane, silicon tetrachloride, and polychlorosilane called polymer, which has a higher boiling point than silicon tetrachloride. The feed liquid supplied to the column is heated in the reboiler 12 at the bottom of the column. Dichlorosilane and trichlorosilane with low boiling point become vapors and are discharged from the top of the tower, and are liquefied in the condenser 11 to form a mixed solution of high-purity dichlorosilane and trichlorosilane. A part o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com