Device for bearing transparent conductive film glass during thinning single surface and thinning method for transparent conductive film glass

A technology of a transparent conductive film and a bearing device is applied in the field of a bearing device for single-sided thinning of a transparent conductive film glass to achieve the effects of reducing the processing cost and simplifying the production process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

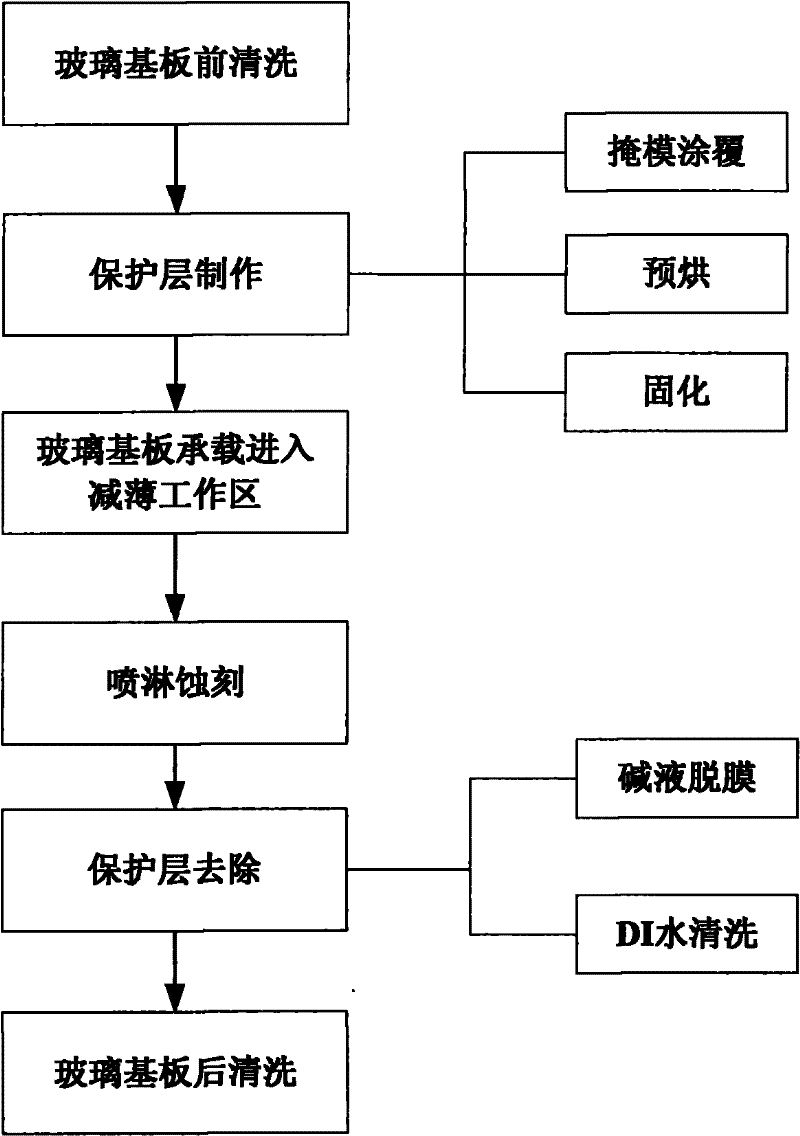

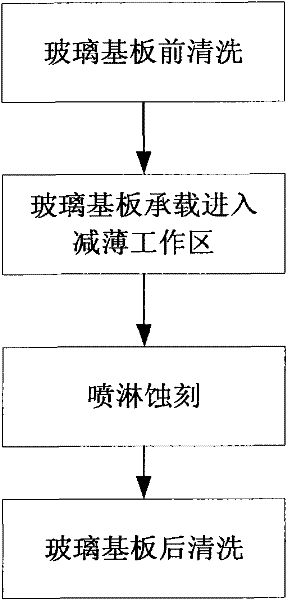

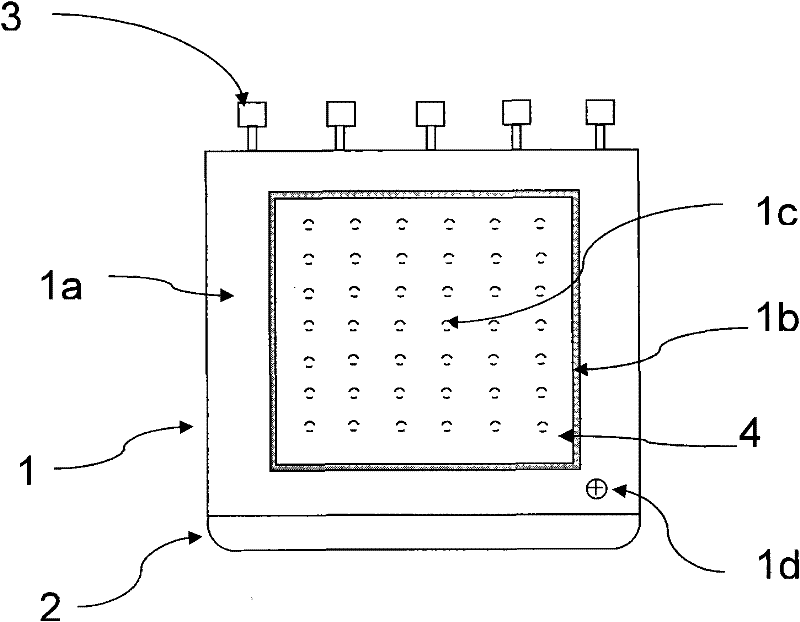

[0044] figure 1 Flowchart of the glass thinning process performed for the prior art. As shown in the figure, the existing technology is to coat the surface that does not need to be etched with a mask as a protective layer before the glass substrate is chemically thinned and etched, and then support the transportation of both ends of the glass substrate from the left and right of the glass transportation direction. The roller realizes the clamping of the glass substrate so as to complete the thinning process (as described in the patent of CN1669967A), and its manufacturing process is as followsfigure 1 As shown, the disadvantage of this technology is that it adds a lot of extra operations other than thinning, which leads to an increase in cost, such as: adding protective layer coating, drying, and removal processes, increasing raw material costs and manufacturing processes , which increases the difficulty of controlling the yield rate and reduces production efficiency; increase...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com