Preparation method of dihydric alcohol

A dihydric alcohol, mannitol technology, applied in the preparation of organic compounds, chemical instruments and methods, preparation of hydroxyl compounds, etc., can solve problems such as expensive nickel/ruthenium catalysts, and achieve small restrictions, low prices, and wide raw material sources. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] A certain amount of sorbitol and mannitol are dissolved in water to prepare an aqueous solution containing 20% by mass of sorbitol and 5% by mass of mannitol. Take 300g of this solution and add it to a 500mL autoclave, add 25g of nickel-molybdenum-copper-chromium catalyst, adjust the pH to 13 with sodium hydroxide, close the autoclave, pressurize the autoclave, vacuumize it after leak testing with nitrogen, and replace it with hydrogen for 3 times , and then heated to raise the temperature. After the reaction temperature rose to 240°C, hydrogen was charged until the reaction pressure was 11MPa to start the catalytic hydrocracking reaction. After 1 hour of reaction, samples were taken and analyzed by high-pressure liquid chromatography. The product composition and distribution were: Alcohol 22.7%, propylene glycol 62%, butanediol 7.8%, other 5.2%, remaining sorbitol and mannitol total 2.3%.

Embodiment 2~ Embodiment 8

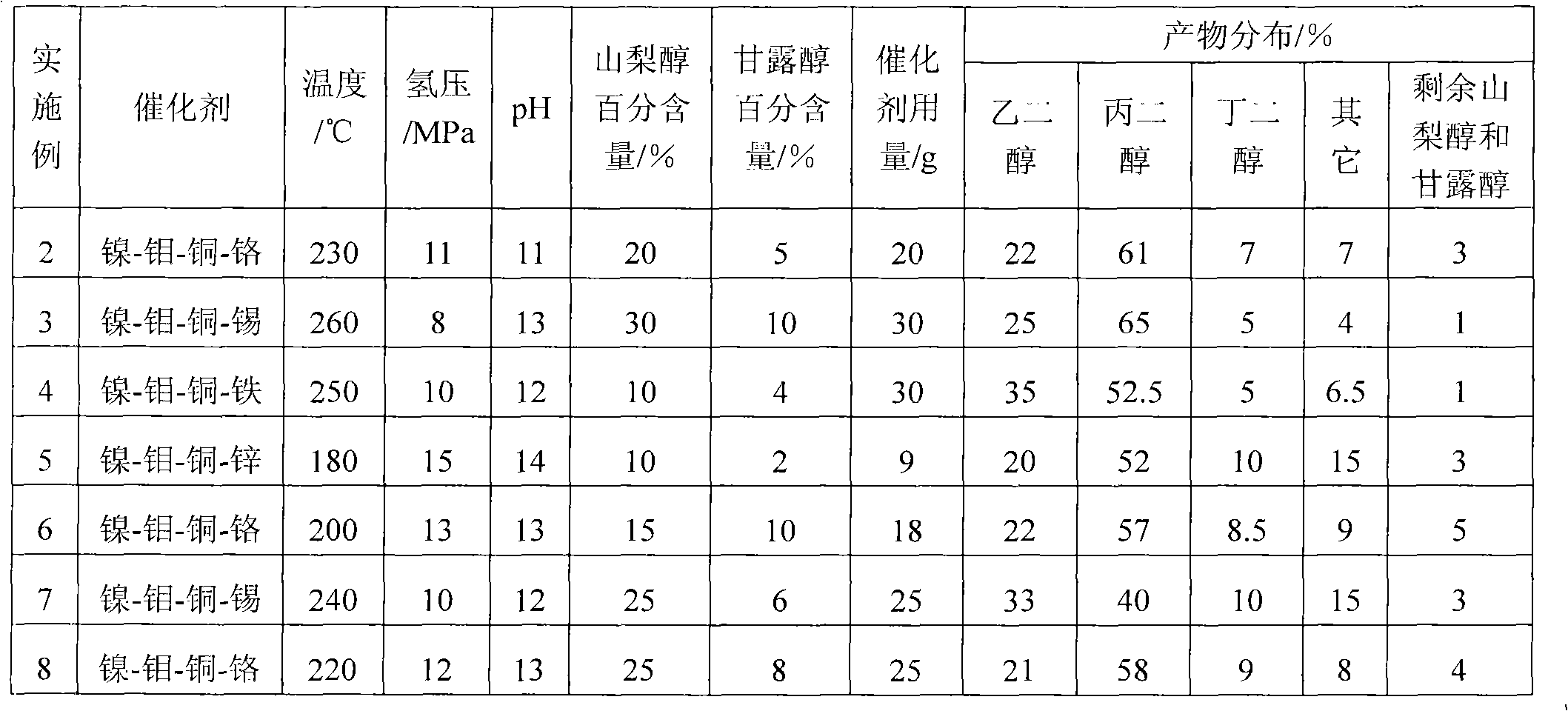

[0018] The experimental method is basically the same as in Example 1, except that the catalysts and reaction conditions used are different, and the product distribution also has certain differences, as shown in Table 1.

[0019] Table 1 Reaction conditions and results of Embodiment 2 to Embodiment 8

[0020]

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap