Lower-half cylinder temperature compensation device of cylinder and temperature compensation method thereof

A temperature compensation device and temperature compensation technology, applied in the direction of engine components, machines/engines, mechanical equipment, etc., can solve problems such as large rotor deflection, dynamic and static friction, and increased temperature difference, so as to avoid operation problems and ensure safe operation. even heating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

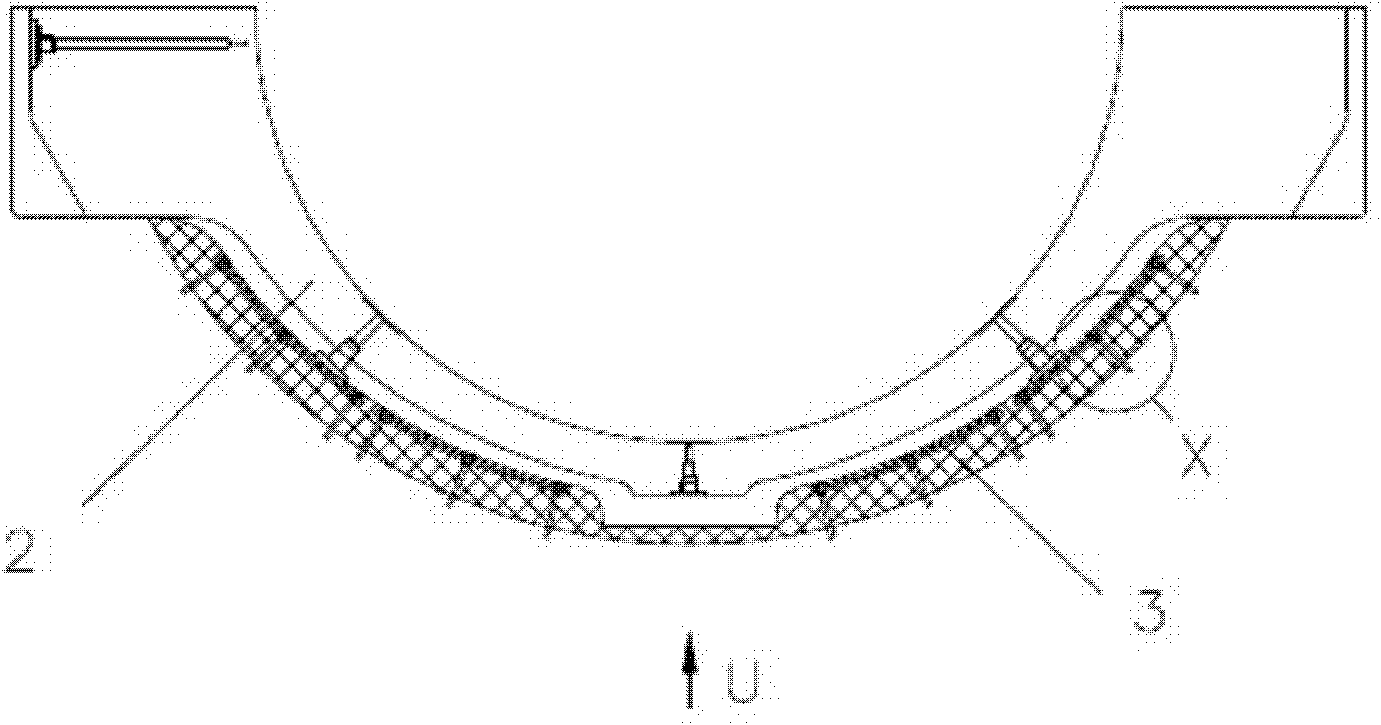

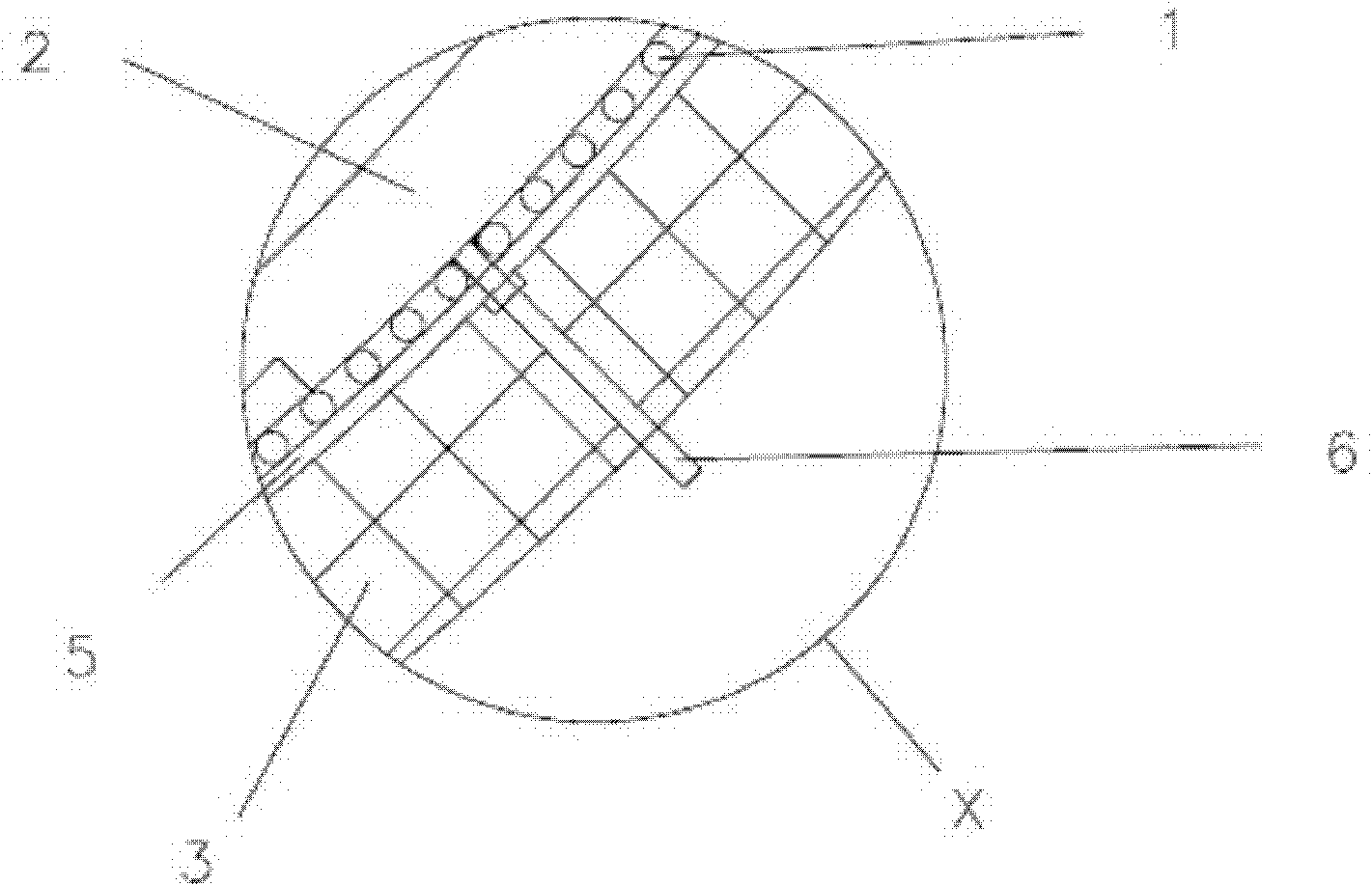

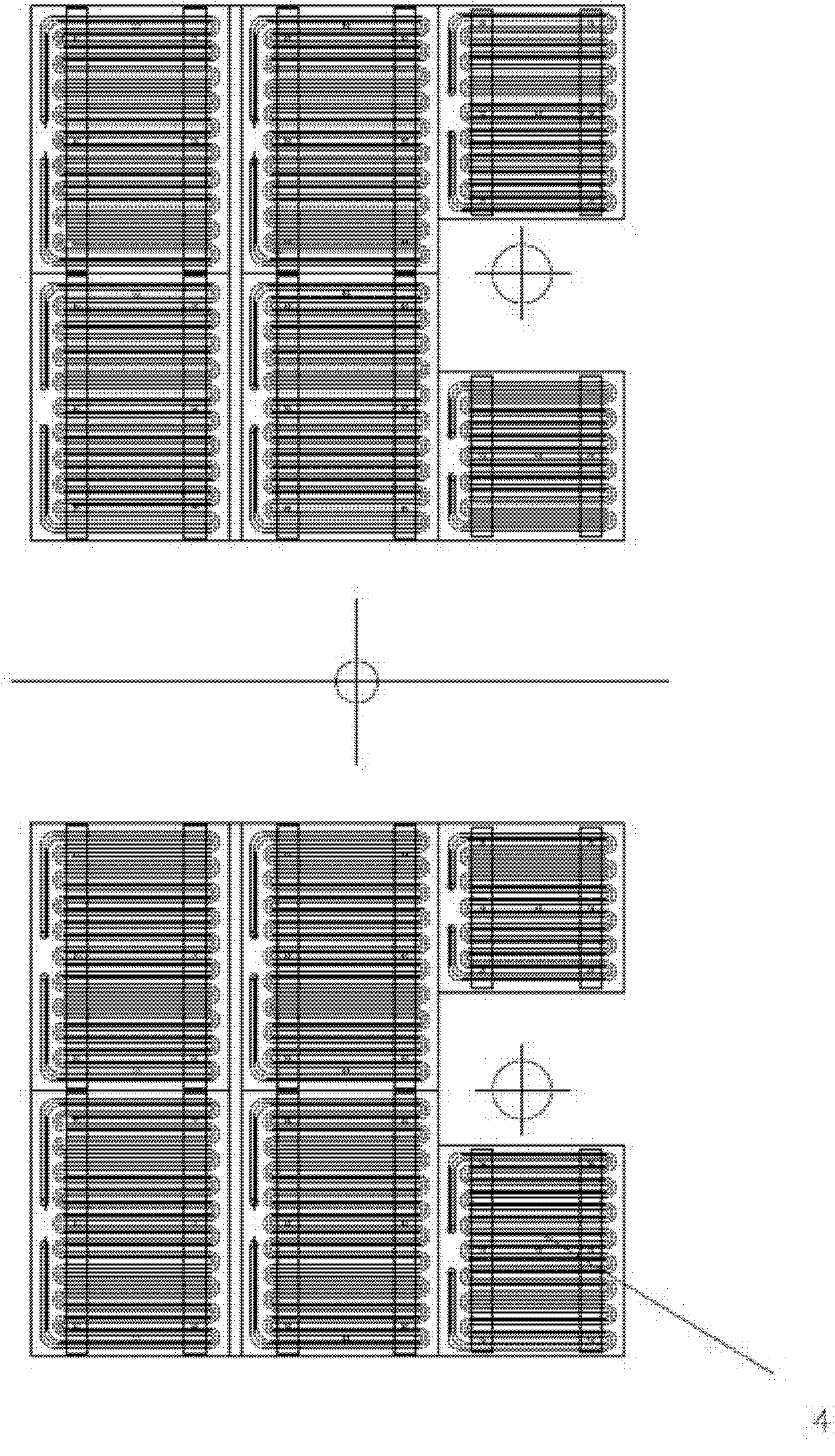

[0023] Such as figure 1 , 2 As shown, the temperature compensation device for the lower half of the cylinder described in this embodiment mainly includes an electric heating tube 1, and the electric heating tube 1 is fixedly arranged on the outside of the lower half cylinder 2 of the cylinder, and the outside of the electric heating tube 1 An insulating layer is provided, and the insulating layer is a rare earth layer 3 . Such as image 3 As shown, the electric heating tube 1 is composed of a heating tube monomer 4, and the heating tube monomer 4 is arranged on the outer surface of the lower half cylinder 2 of the cylinder in a coil shape. The bead 5 matching the shape of the lower half cylinder 2 of the cylinder is positioned and connected with the lower half cylinder 2 of the cylinder, and the electric heating tube 1 is fixed between the bead 5 and the lower half cylinder 2 of the cylinder. The positioning connection is that a bolt 6 is welded on the outer surface of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com