High-voltage switch contact temperature online monitoring device and method thereof

A high-voltage switch and monitoring device technology, applied in measuring devices, thermometers, electrical devices, etc., can solve problems such as difficulty in replacement and inability to replace

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

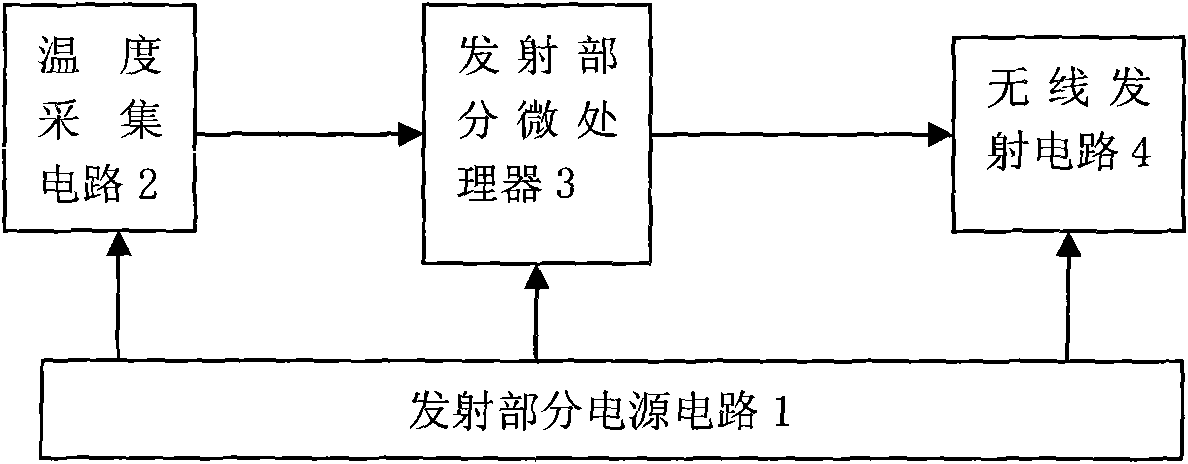

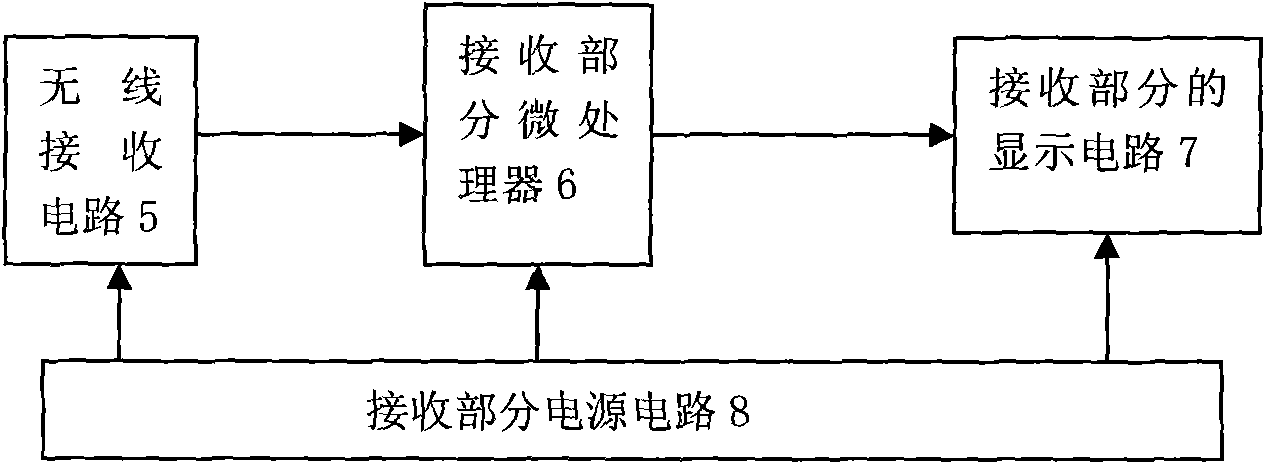

[0013] See figure 1 , figure 2 , image 3 As shown, the high-voltage switch contact temperature online monitoring device of this embodiment includes a power supply circuit of the transmitting part, a temperature acquisition circuit, a microprocessor of the transmitting part, a wireless transmitting circuit, a wireless receiving circuit, a microprocessor of the receiving part, and a The display circuit and the receiving part of the power supply circuit are composed.

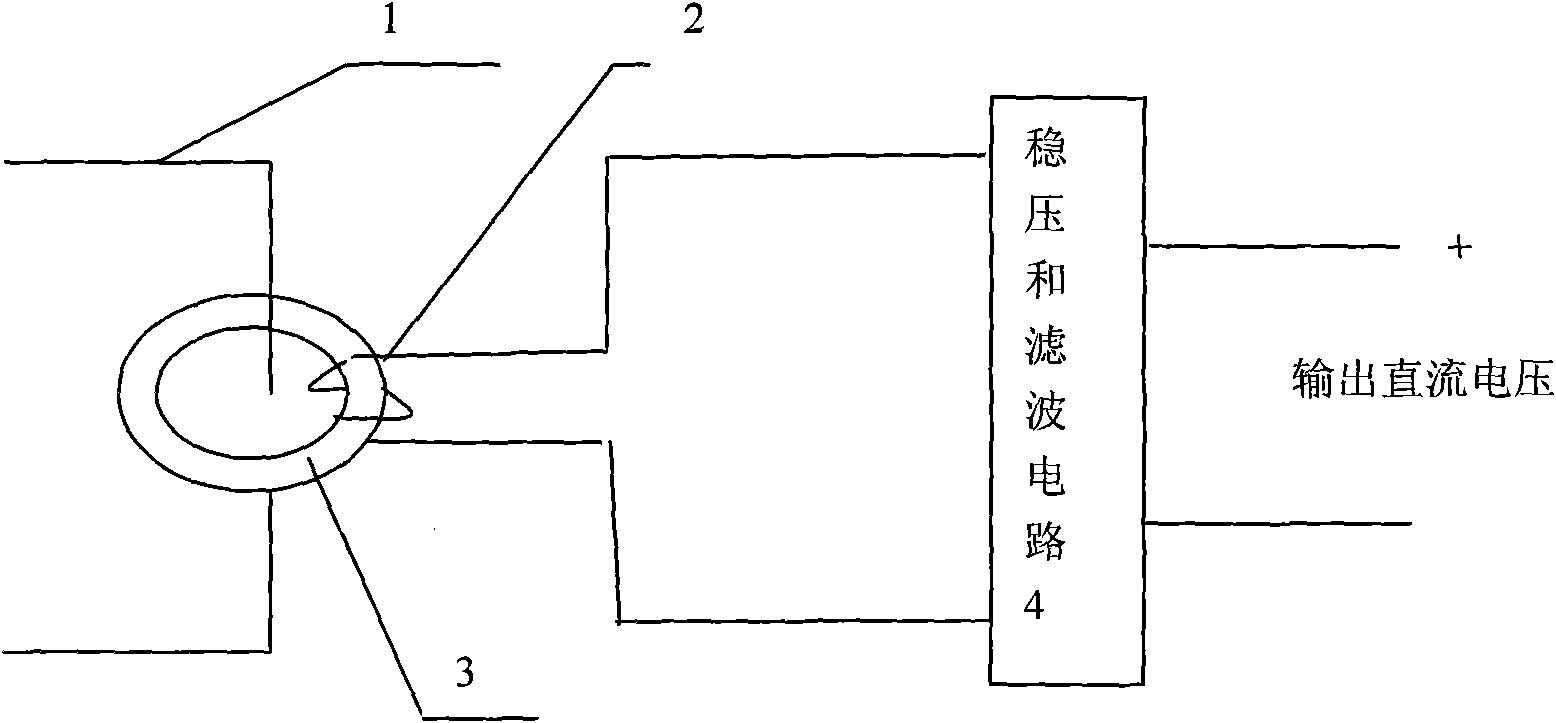

[0014] The principle of the power supply circuit of the transmitting part is as follows: image 3 As shown, it consists of a current induction coil, an iron core of high magnetic permeability material, a voltage regulator and a filter circuit. The power supply method uses the principle of electromagnetic induction, and the ferromagnetic transformer induces the AC power from the high-voltage bus, and then rectifies it. , filtering, and voltage stabilization to supply power to the high-voltage side circuit. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com