Filtering endoscope used for optical fiber laser and optical fiber laser

A fiber laser and filter cavity technology, which is applied in the field of filter cavity mirrors, can solve the problems of damage to gratings and common coatings, affect performance, ablation, etc., achieve high damage threshold cavity mirrors, be easy to implement, and improve the effect of beam quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

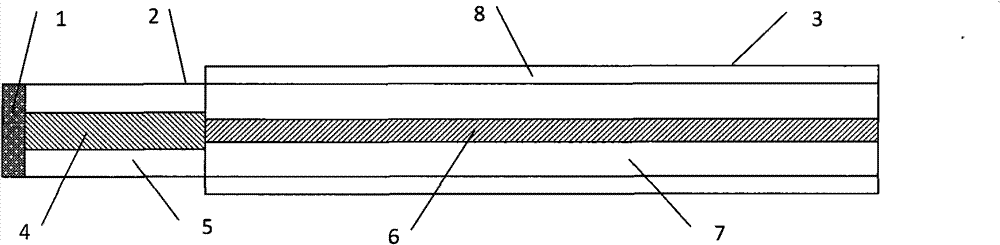

Method used

Image

Examples

Embodiment 1

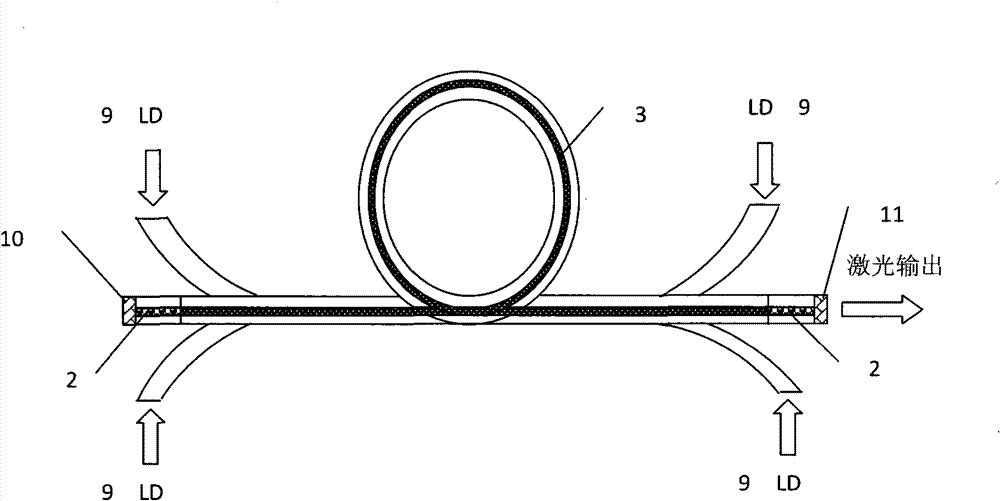

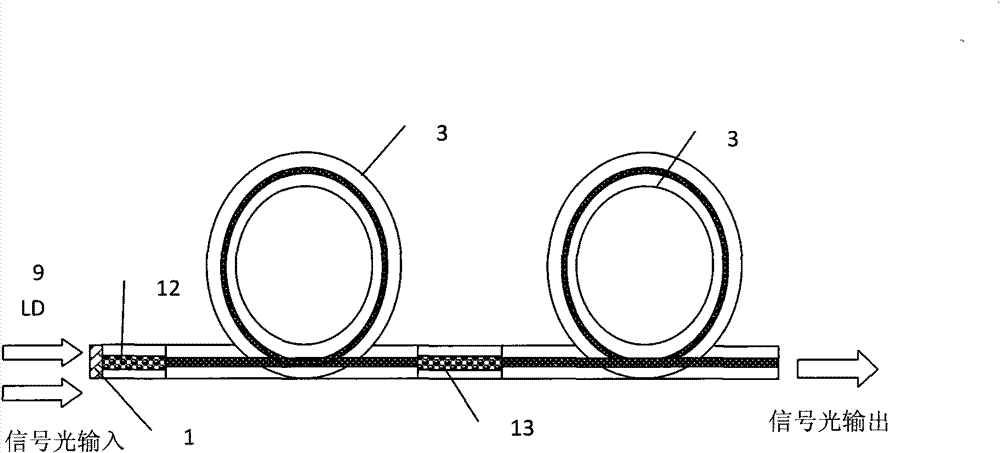

[0037] Such as figure 2 As shown, this embodiment is a fiber laser using a filter cavity mirror. LD pumping source (9), end-face coatings (10), (11), double-clad fiber (3) and filter fiber (2) form a basic Fabry-Perot resonant cavity, and coatings (10), (11) at both ends of the fiber ) as a laparoscope. The coated cavity mirror (10) at the left end is highly transparent to the pump light and highly reflective to the fiber laser; the coating (11) as the output cavity mirror is highly transparent to the pump light and partially transparent to the fiber laser. The numerical aperture of the double-clad optical fiber (3) is larger, and the numerical aperture of the filter optical fiber (2) is smaller. The core diameters of the two types of optical fibers are the same, the cladding structure is the same, and the refractive index distribution of the cross section adopts a step distribution. The pump light is injected into the inner cladding of the fiber from the side to excite las...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com