Mover cooling method and device for machine tool

A cooling method and cooling device technology, which are applied to metal processing machinery parts, large fixed members, maintenance and safety accessories, etc., can solve the problems of high price of machine tools, and achieve the effects of reduced supply, shortened paths, and stable machining accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

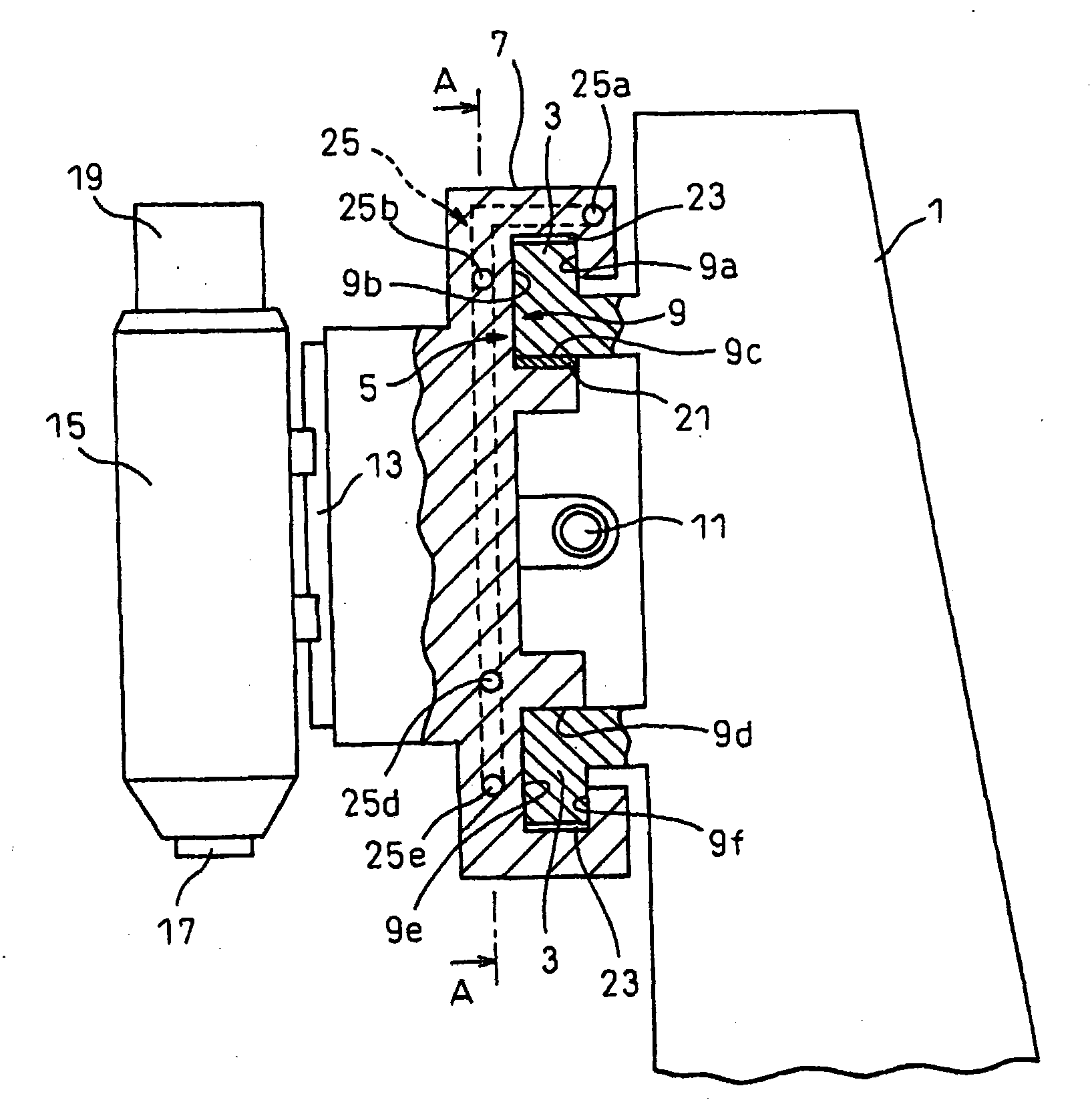

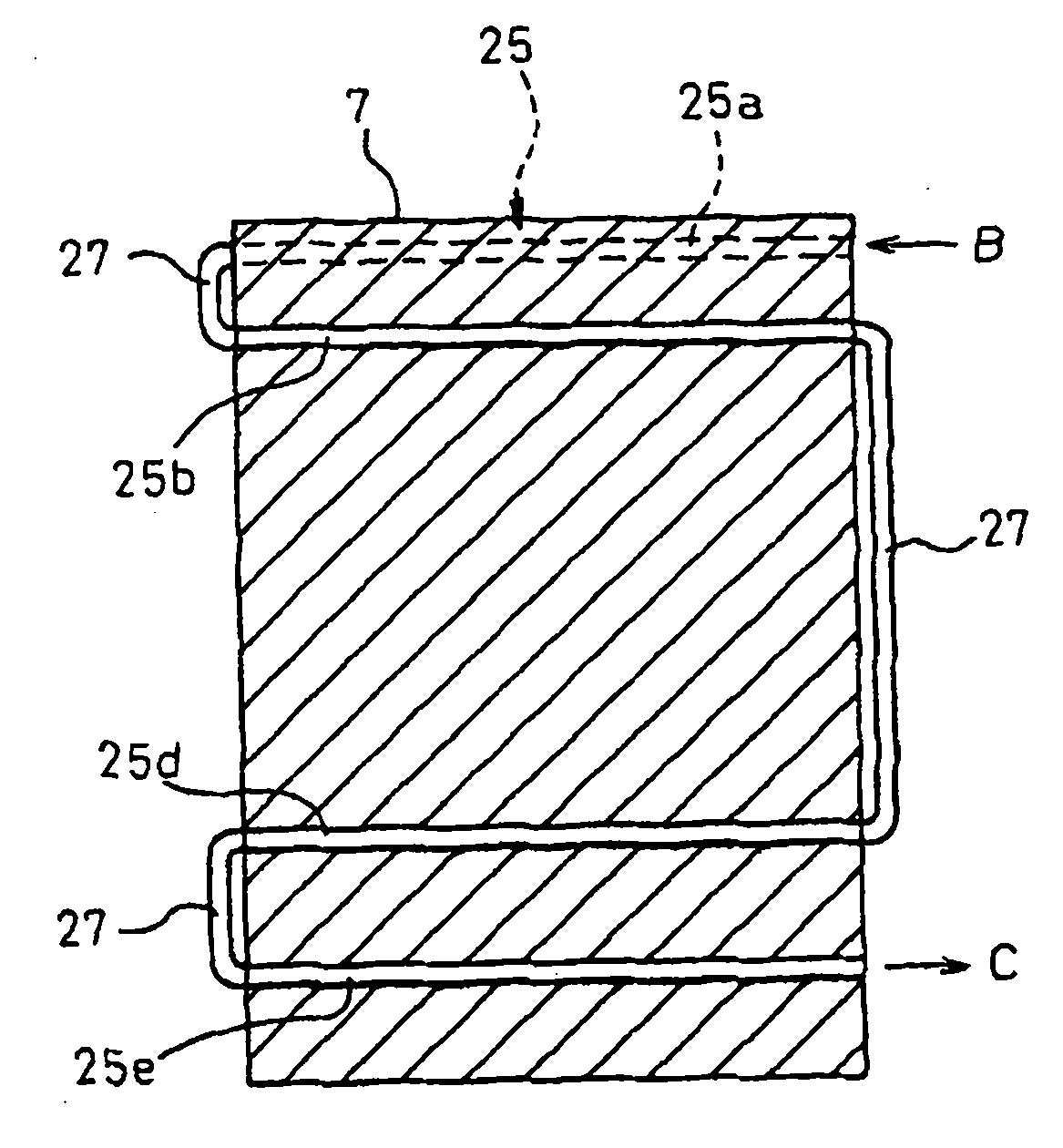

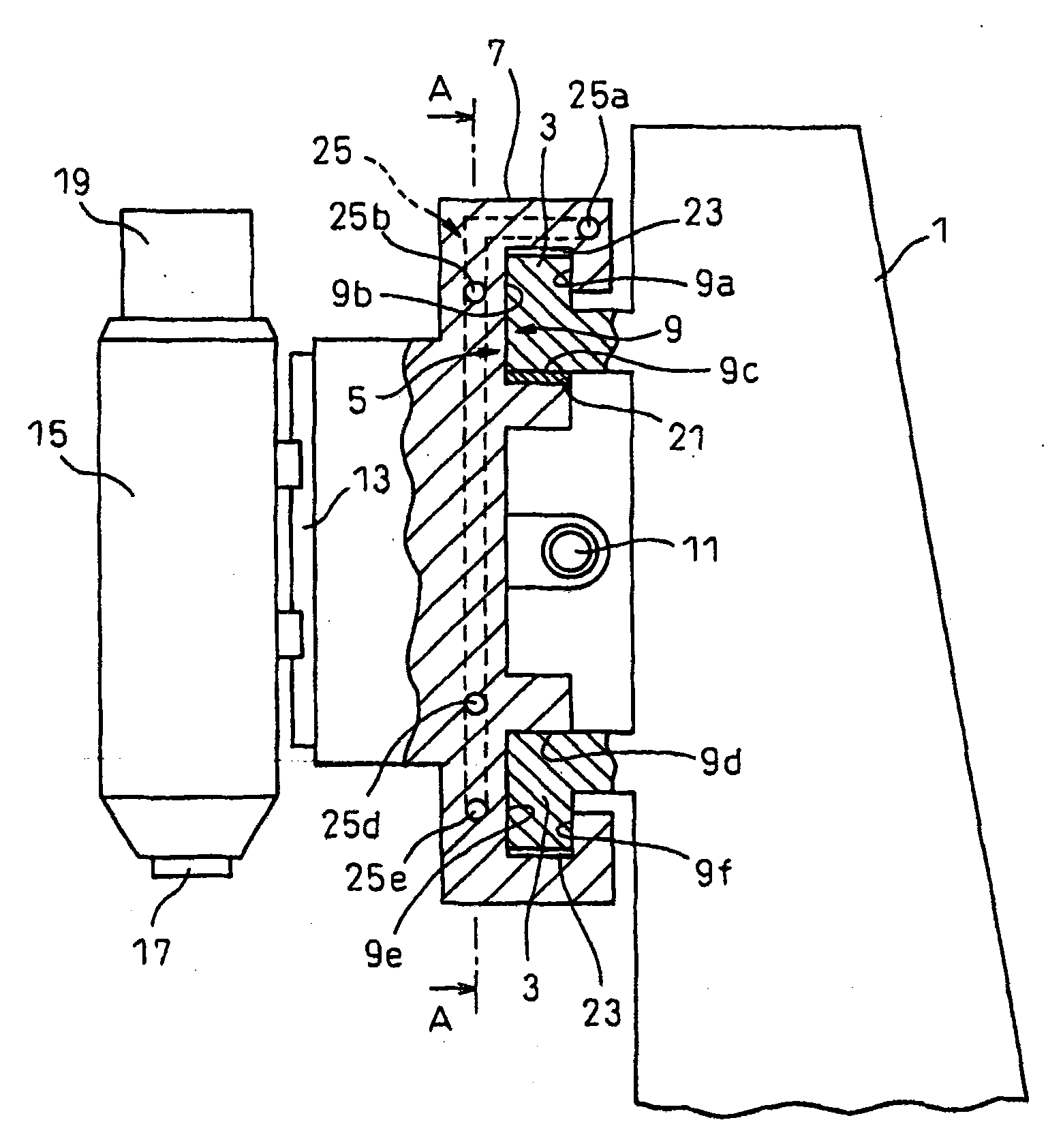

[0016] Hereinafter, preferred embodiments of a cooling method and a cooling device for a moving body of a machine tool according to the present invention will be described with reference to the drawings. figure 1 It is a side view showing an embodiment of a cooling device for a moving body of a machine tool according to the present invention. figure 1 The machine tool shown is a vertical machining center, and the column 1 is erected on a bed which is not shown. On the front face of the column 1, a pair of guide rails 3 are arranged up and down, and the guide rails 3 are arranged in parallel in a direction perpendicular to the paper surface. The guide rail 3 is a square guide rail with a plurality of guide surfaces 5 . A sliding seat frame 7 is suspended on the guide rail 3 , and the sliding surface 9 of the sliding seat frame 7 engages with the guide surface 5 of the guide rail 3 . The slide frame 7 is movable on the guide rail 3 by a driving device not shown and a feed scre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com