Terminal

A terminal and production method technology, applied in the direction of comprehensive factory control, instrumentation, comprehensive factory control, etc., can solve the problems of increased wiring man-hours, increased maintenance time, and increased equipment costs, so as to prevent confusion in the appearance, reduce the number of wiring, Achieving System Cost Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

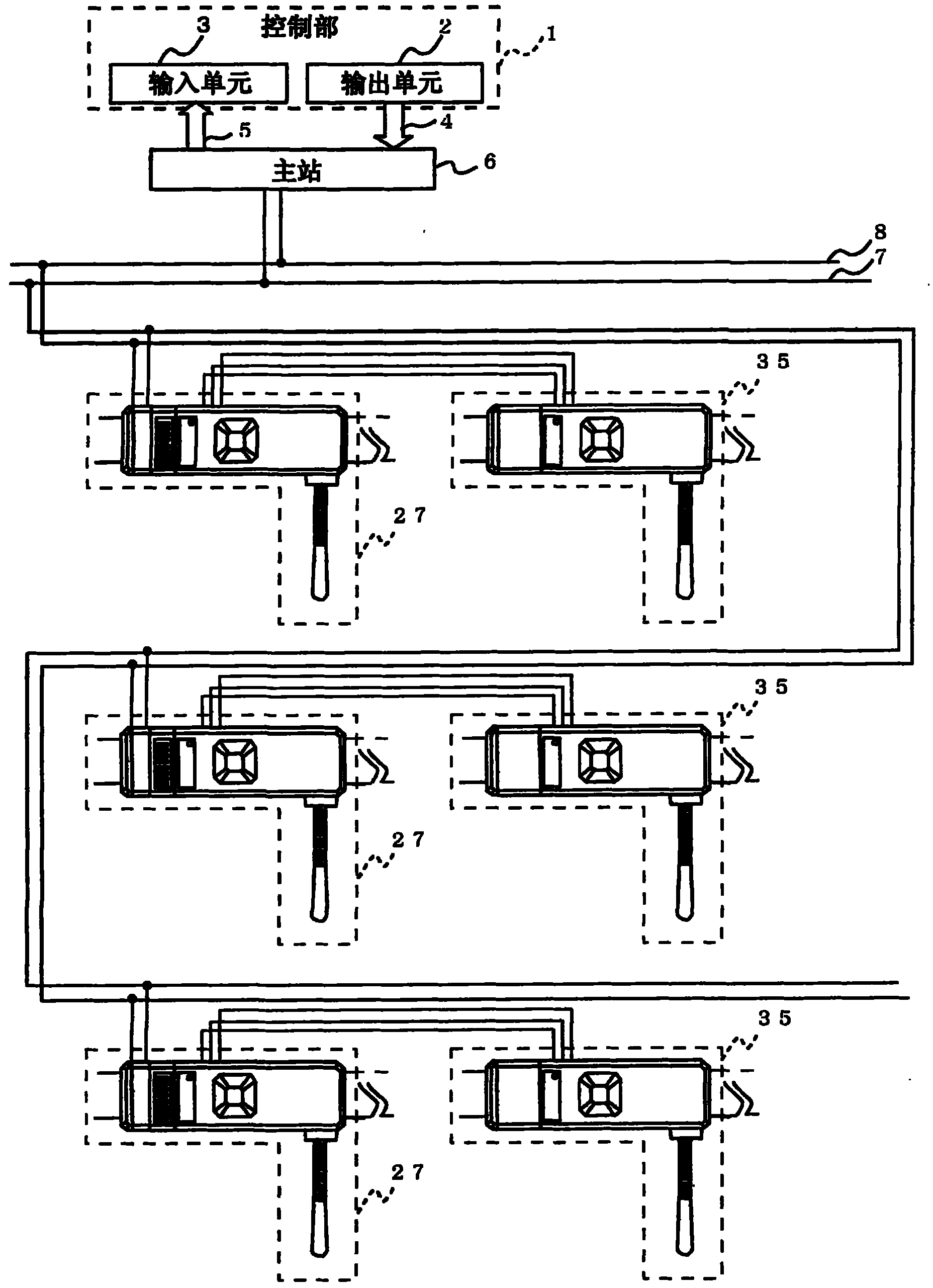

[0070] use Figure 1 to Figure 5 Examples of the present invention will be described.

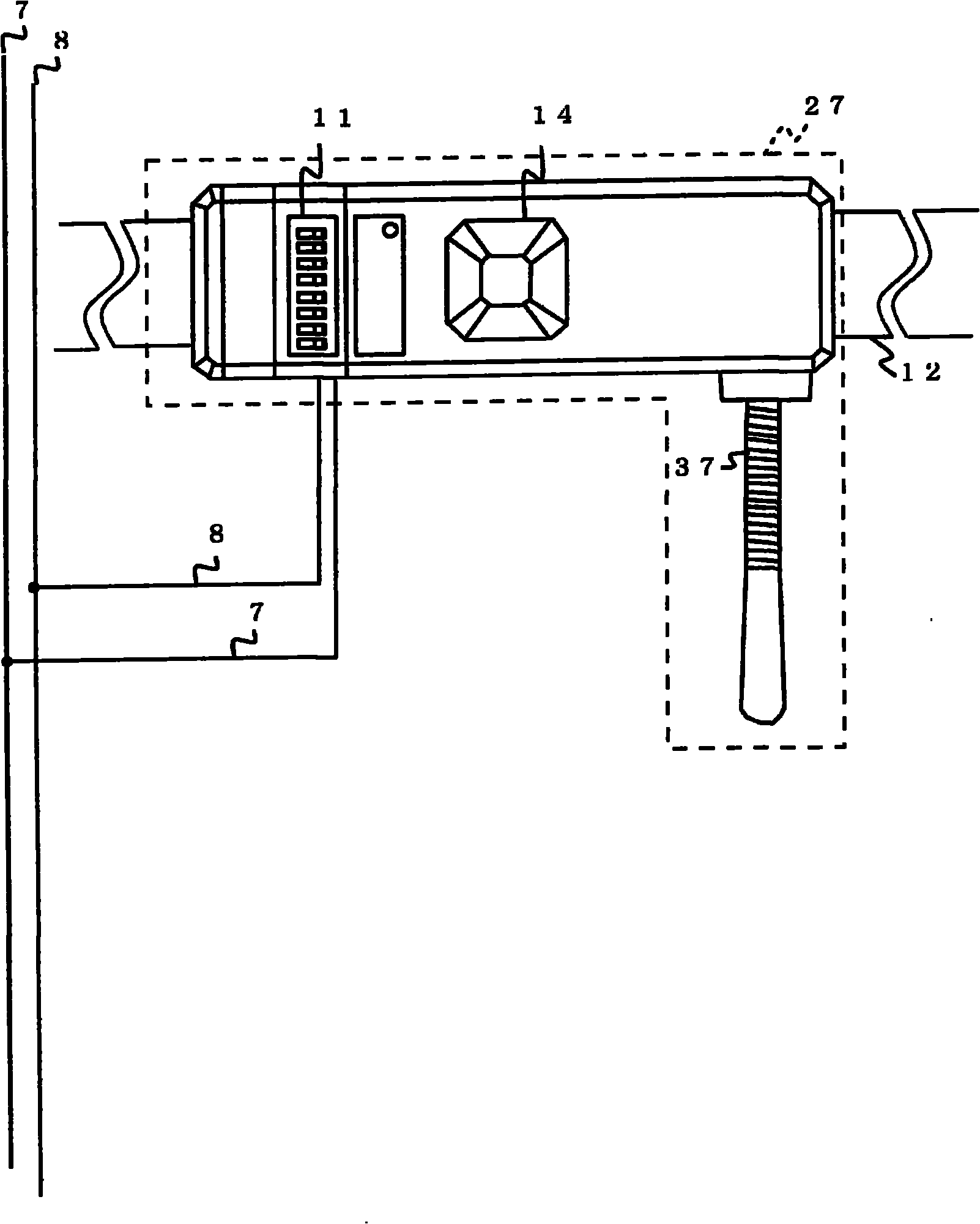

[0071] figure 1 An example of a terminal according to the present invention is shown.

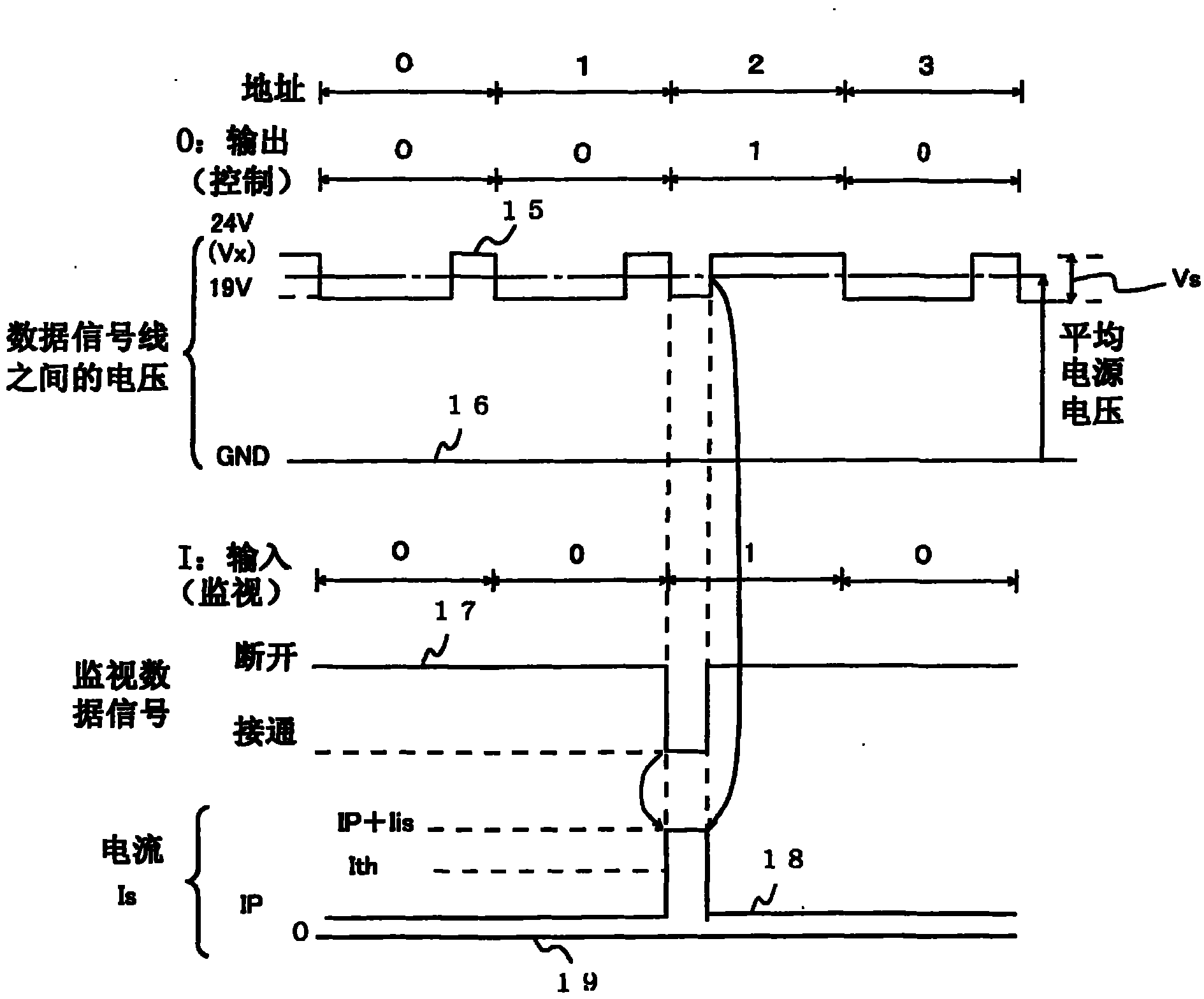

[0072] The slave station terminal 27 is connected to the D+ power superimposition common data signal line 7 and the D- power superimposition common data signal line 8, and includes a slave station address unit 11 for setting the own station address, a display lamp 14 and an input switch 37. The slave station terminals 27 are fixed to the tubes 12 for tube racks at predetermined intervals in consideration of the size and shape of the components. There is a component delivery rack behind the pipe rack, and it has a space that matches the size and quantity of the components. When the shelf is empty after picking up the components from the front, the components are replenished from the rear.

[0073] After the worker, the working robot or the automatic transport device AGV takes out the component from the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com