Water-cooled or air-cooled high-temperature horizontal cyclone separator of circulating fluidized bed with accelerating section

A technology of cyclone separator and circulating fluidized bed, which is applied in the direction of the device whose axial direction of the cyclone can be reversed, the cyclone device, etc., which can solve the problems of large volume, high cost and complex structure of the separator, and reach the application range wide, low cost, and compact overall layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

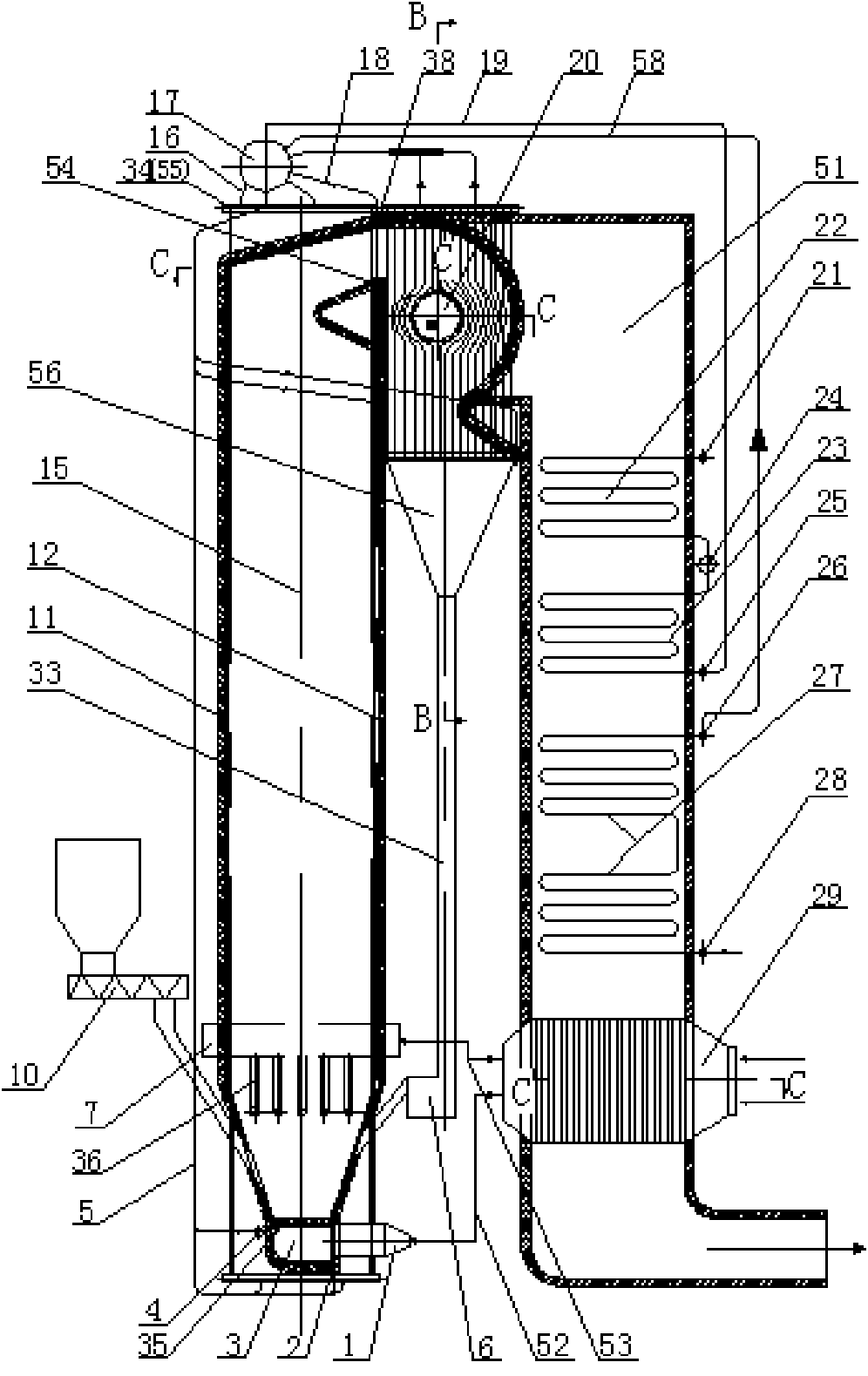

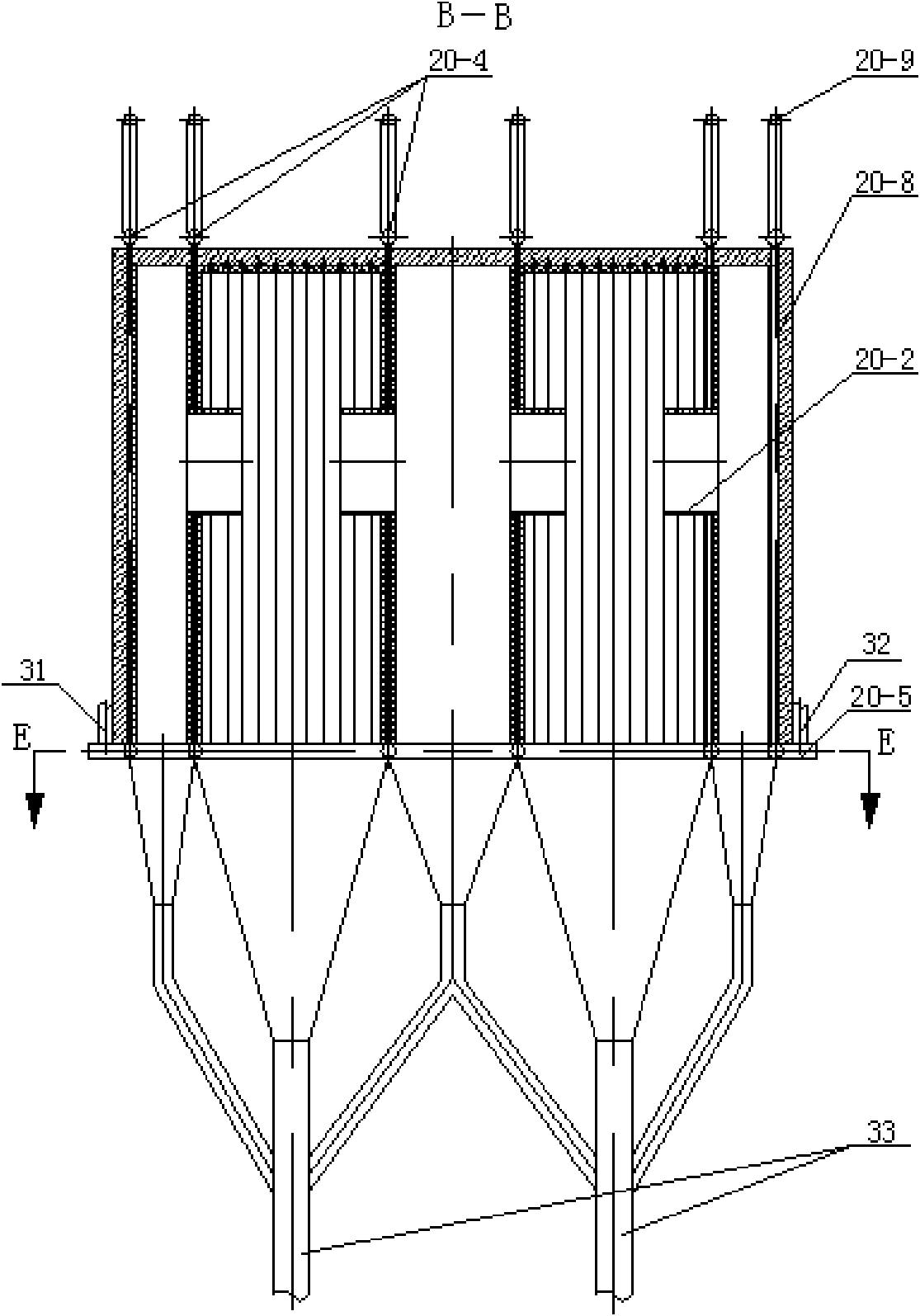

[0016] The quantity of the water-cooled separation chamber 20-16 and the quantity of the steam-cooled separation chamber 50-1 are determined according to the boiler capacity.

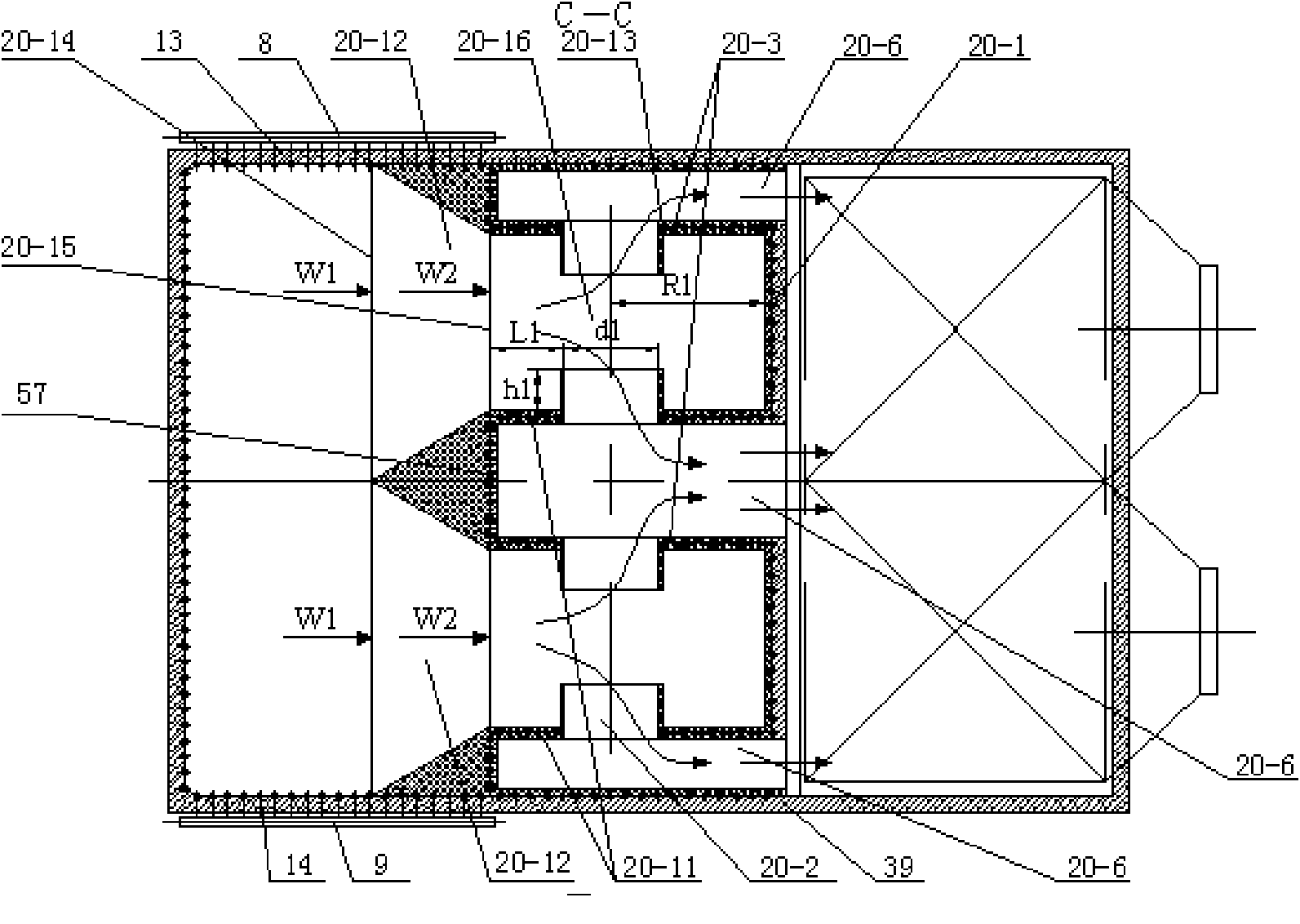

[0017] In this embodiment, the smoke velocity W1 at the inlet port 20-14 of the first acceleration section 20-12=16-20m / s, and the smoke velocity W2=25-30m at the outlet port 20-15 of the first acceleration section 20-12 / s.

[0018] Specific implementation mode two: combination image 3 To illustrate this embodiment, the first left membrane water wall 20-3, the first right membrane water wall 20-11 and the arc-shaped membrane water wall 20-1 in this embodiment are all surface-covered refractory and wear-resistant castings. The membrane-type water-cooled wall of the material can prevent the internal wear of the separator and prevent high-temperature coking. The inner diameter d1=(0.75-1.0)R1 of the first exhaust pipe 20-2 of this embodiment, the height h1=(0.5-0.75)R1 of the first exhaust pipe 20-2, t...

specific Embodiment approach 2

[0019] Specific implementation mode three: combination Figure 7 Describe this embodiment, the first left membrane type vapor cooling wall 50-6, the first right membrane type vapor cooling wall 50-7 and the arc-shaped membrane type vapor cooling wall 50-8 in this embodiment are all surface-covered fire-resistant The membrane-type gas-cooled wall of wear-resistant castable can prevent the internal wear of the separator and prevent high-temperature coking. The inner diameter d2=(0.75-1.0)R2 of the second exhaust pipe 50-2 in this embodiment, the height h2=(0.5-0.75)R2 of the second exhaust pipe 50-2, the second exhaust pipe 50 The distance L2=(0.75-1.0) R2 from the center of -2 to the outlet port 50-11 of the second acceleration section 50-9, R2 is the distance from the center of the second exhaust pipe 50-2 to the arc-shaped film-type gas-cooled wall 50-8 the horizontal distance of the inner surface. With such setting, the separation efficiency reaches 99.5%, and the separato...

specific Embodiment approach 3

[0020] Specific implementation mode four: combination image 3 Describe this embodiment, the quantity of the water-cooled separation chamber 20-16 of this embodiment is two, two water-cooled separation chambers 20-16 are symmetrically arranged side by side, two water-cooled separation chambers 20-16 and the first acceleration section 20-12 connect. Such setting can improve the separation efficiency, and the separation efficiency can reach 99.5%. Others are the same as in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com