Improved grinding wheel spindle using air bearing

An air bearing and spindle technology, which is applied to the parts of grinding machine tools, grinding machines, metal processing equipment, etc., can solve the problems that the accuracy requirements cannot meet the requirements for the use of the grinding wheel spindle of wafer grinding machines, and the noise is high.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

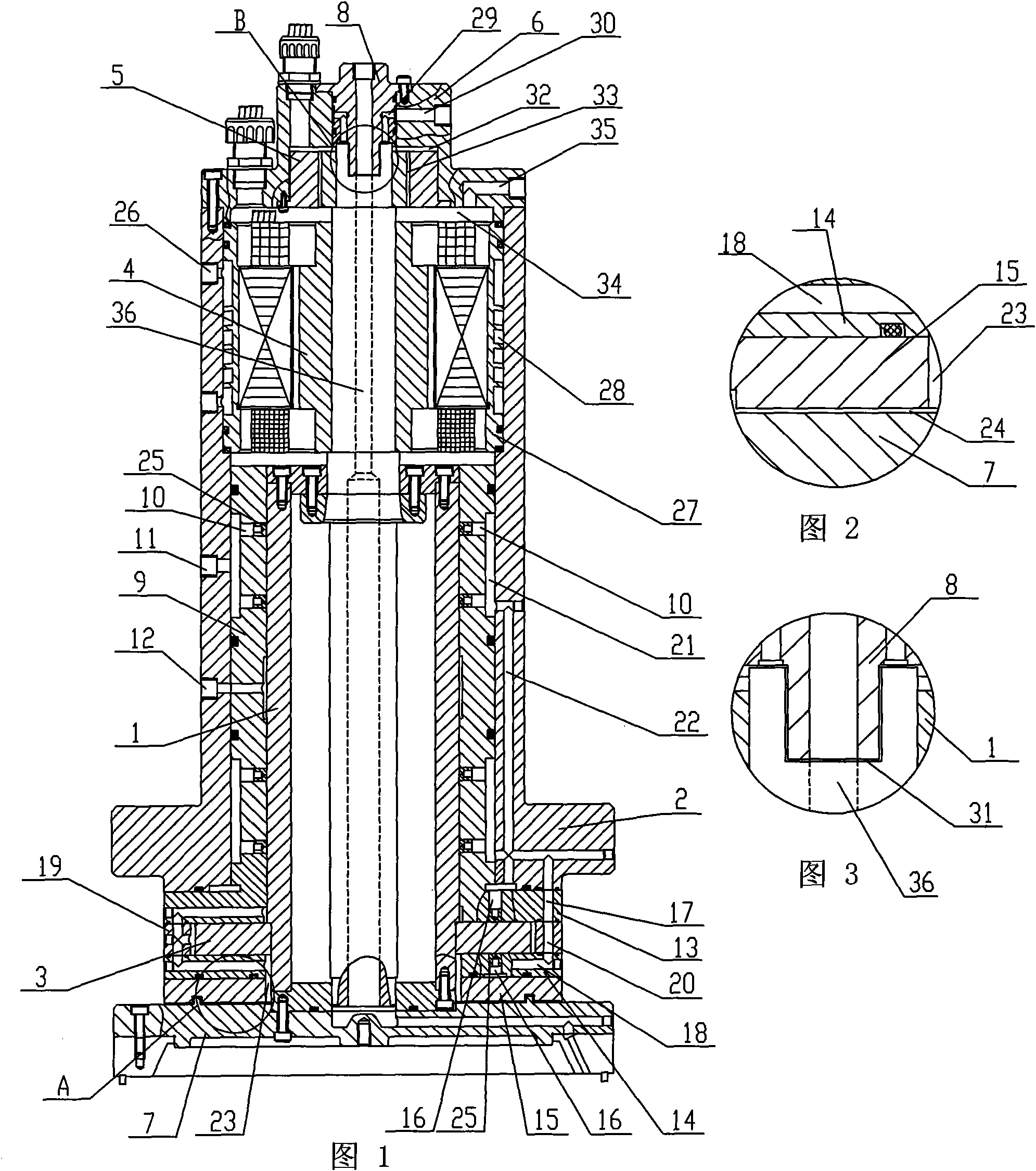

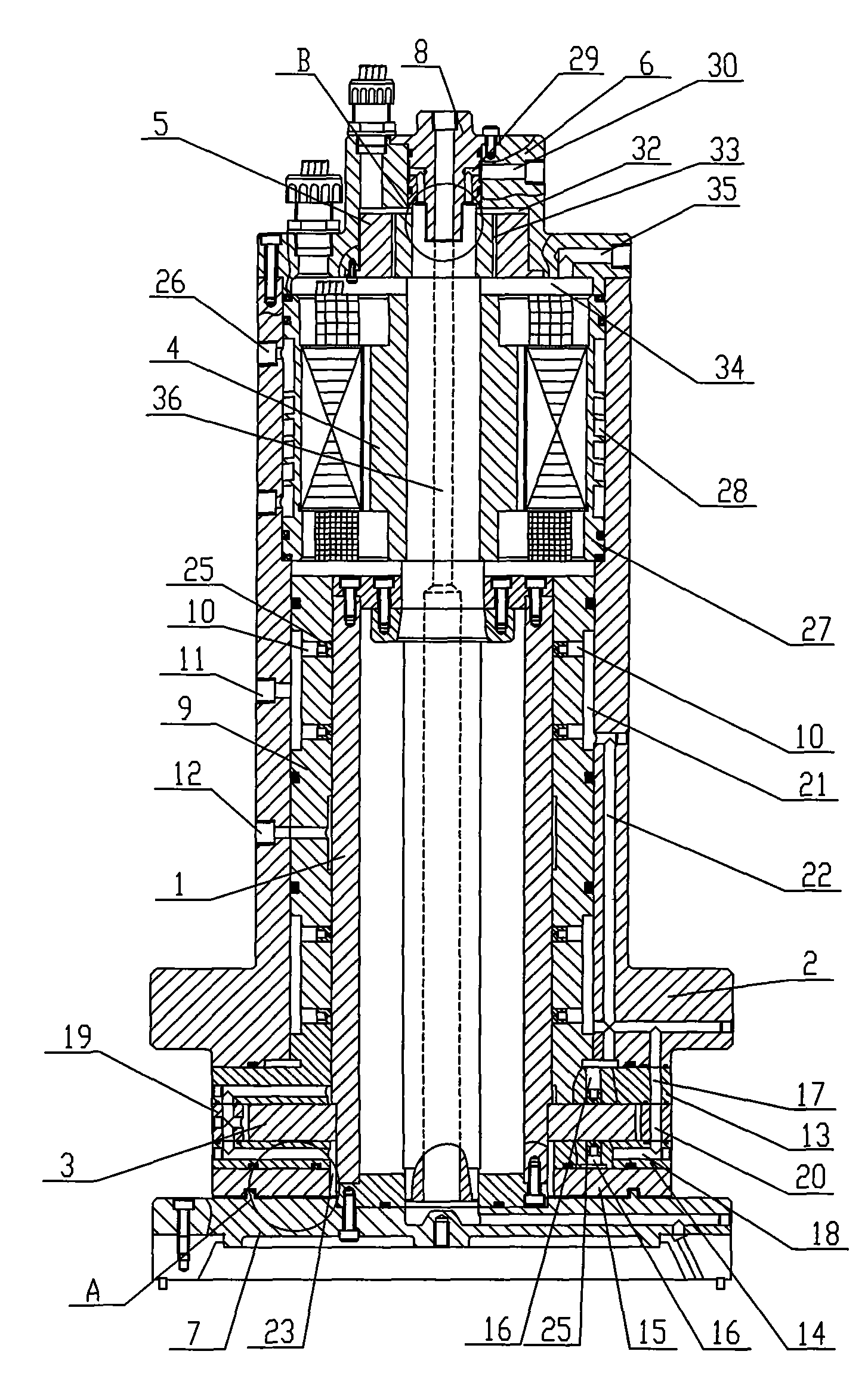

[0014] see figure 1 , figure 2 , image 3 , The present invention includes the rotor spindle 1, the spindle housing 2, the spindle flange 3, the motor 4, the resolver 5, the spindle rear cover 6, the spindle front cover 7, the cooling water connector 8, and the air bearing spindle 9 is sleeved on the spindle housing 2 and the cavity formed by the rotor main shaft 1, radial orifices 10 are evenly distributed on the outer surface of the air bearing main shaft 9, and each radial orifice 10 passes through the air path 21 of the air bearing main shaft 9 and the main shaft housing The air passage 22 inside the body 2 communicates with each other, and the main shaft housing 2 is provided with an air inlet 11 and an air outlet 12 communicating with the radial orifice 10.

[0015] The upper round end of the spindle flange 3 is equipped with a bearing sleeve 13, the lower round end is equipped with an upper thrust bearing 14, a thrust bearing air cover 15 is installed between the upper th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com