Novel high-strength, fatigue-resistant and non-decarburized alloy spring steel and preparation method of steel wire thereof

A fatigue-resistant and high-strength technology, applied in the field of high-strength fatigue-resistant non-decarburized alloy spring steel and its steel wire, and alloy spring steel, can solve the problems of reduced spring fatigue life, failure to meet fatigue life requirements, and poor purity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

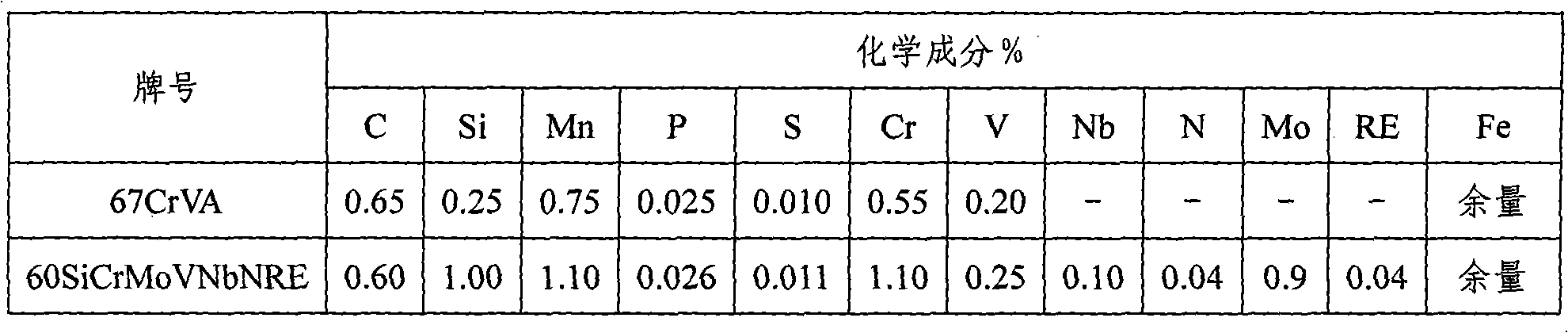

[0064] Embodiment 1 The preparation method of high-strength fatigue-resistant alloy spring steel without decarburization

[0065] 1. Production process:

[0066] Hot metal pretreatment—converter—external refining—continuous casting of 300×400mm billet—flame cleaning—initial rolling of 160mm billet—flaw detection—peeling—heating—continuous rolling and controlled cooling φ5. 5mm wire rod - take-up - inspection - packaging.

[0067] 2. Preparation steps:

[0068] 1) Carry out pretreatment of molten iron by conventional methods, and then enter the converter for steelmaking;

[0069] 2) Calcium oxide and fluorite are used as slagging agents for converter steelmaking. When the carbon content in molten steel reaches 1.00% to 1.10% and the temperature reaches 1550°C to 1570°C, it is transferred to the VAD refining furnace;

[0070] 3) Use iron sheets to wrap various ferroalloy powders separately, and add Mo-Fe alloy for alloying during the refining and oxidation period outside the ...

Embodiment 2

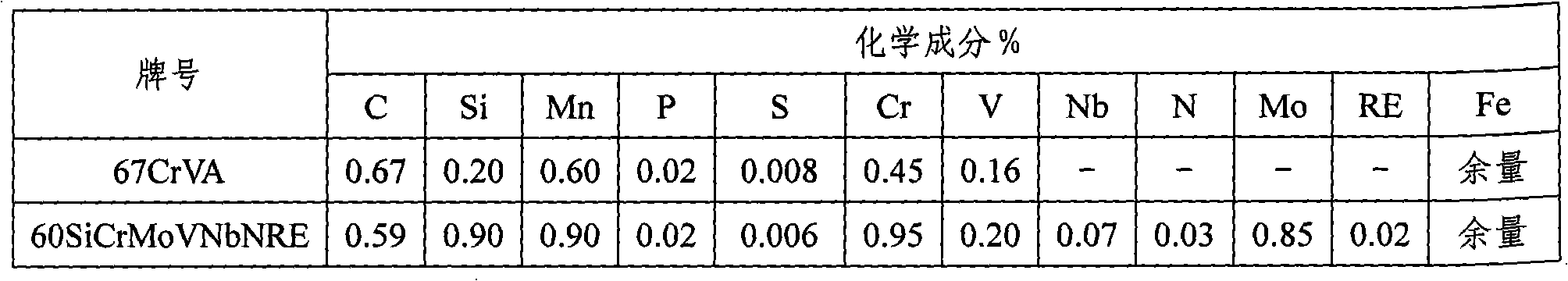

[0080] Embodiment 2 The preparation method of high-strength fatigue-resistant alloy spring steel without decarburization

[0081] 1. Production process:

[0082] Hot metal pretreatment—converter—external refining—continuous casting of 300×400mm billet—flame cleaning—initial rolling of 160mm billet—flaw detection—peeling—heating—continuous rolling and controlled cooling φ5. 5mm wire rod - take-up - inspection - packaging.

[0083] 2. Preparation steps:

[0084] 1) Carry out pretreatment of molten iron by conventional methods, and then enter the converter for steelmaking;

[0085] 2) Fluorite and calcium oxide are used as slagging agents for converter steelmaking. When the carbon content in molten steel reaches 1.00-1.10% and the temperature reaches 1570°C, it is transferred to the VAD refining furnace;

[0086] 3) Use iron sheets to wrap various iron alloy powders respectively, and add Mo-Fe alloy for alloying during the refining and oxidation period outside the furnace; dur...

Embodiment 3

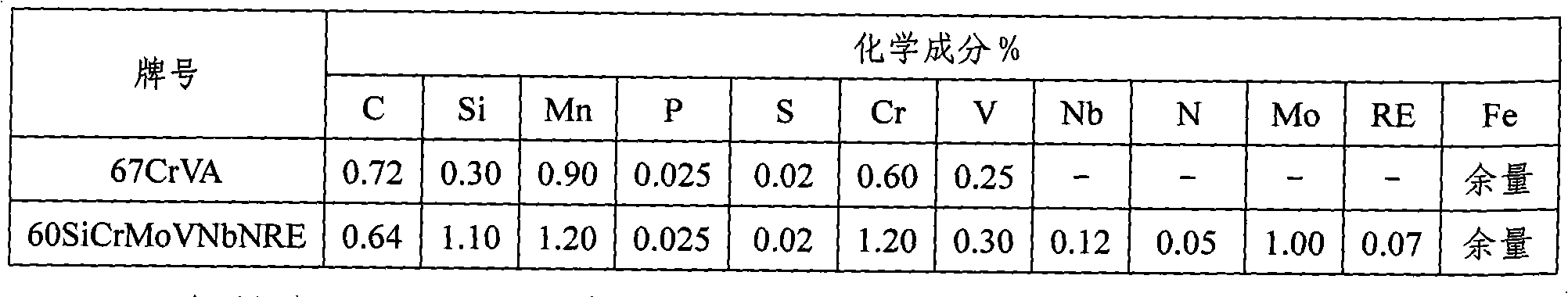

[0096] Embodiment 3 The preparation method of high-strength fatigue-resistant alloy spring steel wire without decarburization

[0097] Prepare high-strength fatigue-resistant non-decarburization alloy spring steel according to the method substantially the same as Example 1, the difference is only: the ratio of controlling [Nb+V] / [N] is 8.4; according to the content of [S] in the steel The content control [RE] / [S] ratio is 3.5, so that the [RE] content of the final steel reaches 0.07%.

[0098] Get the alloy spring steel of gained, prepare steel wire according to the following method:

[0099] 1. Production process:

[0100]φ5.5mm wire rod pay-off——mechanical shelling—peeling—rewinding and payout—annealing—rewinding and payout—drawing to φ2.0mm—rewinding and payout—gas protection heating—oil quenching ——Tempering——Flaw detection——Take-up——Inspection——Packaging.

[0101] 2. Preparation steps:

[0102] 1) After the φ5.5mm wire rod is paid out, it is mechanically peeled and st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com