Continuously-operated supergravity multistage concentric cylinder type electrolytic reaction device and process thereof

An electrolytic reaction, concentric circle technology, applied in the electrolytic process, electrolytic components, cells, etc., to achieve the effect of reducing internal resistance, energy consumption, and small equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

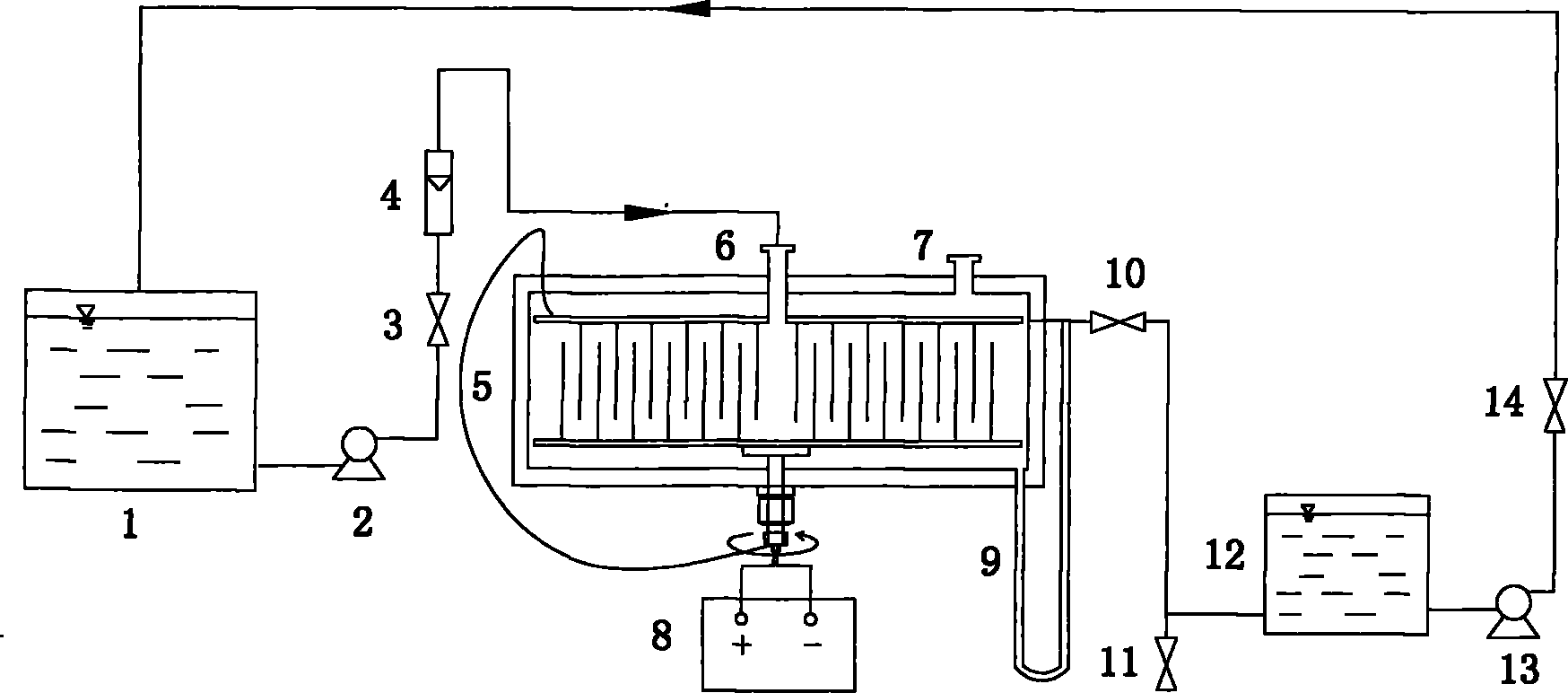

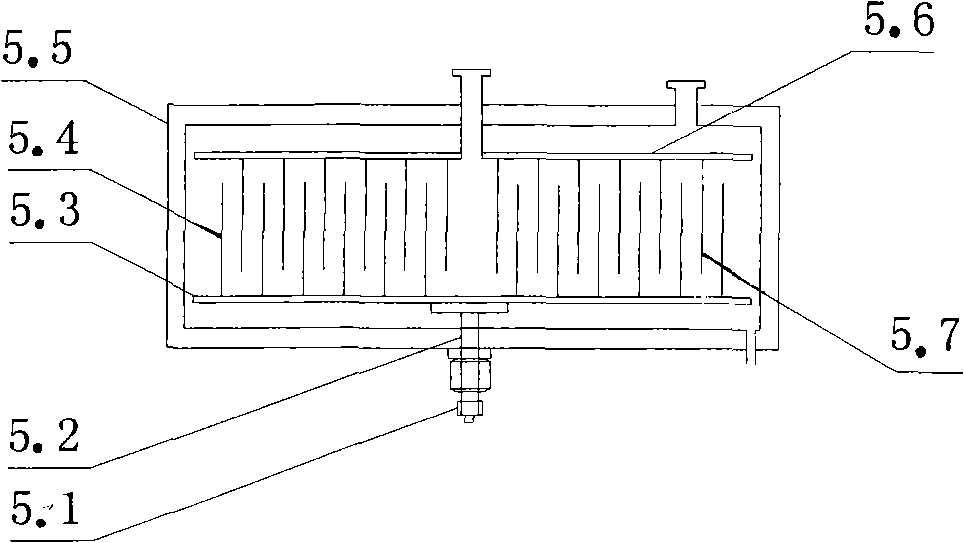

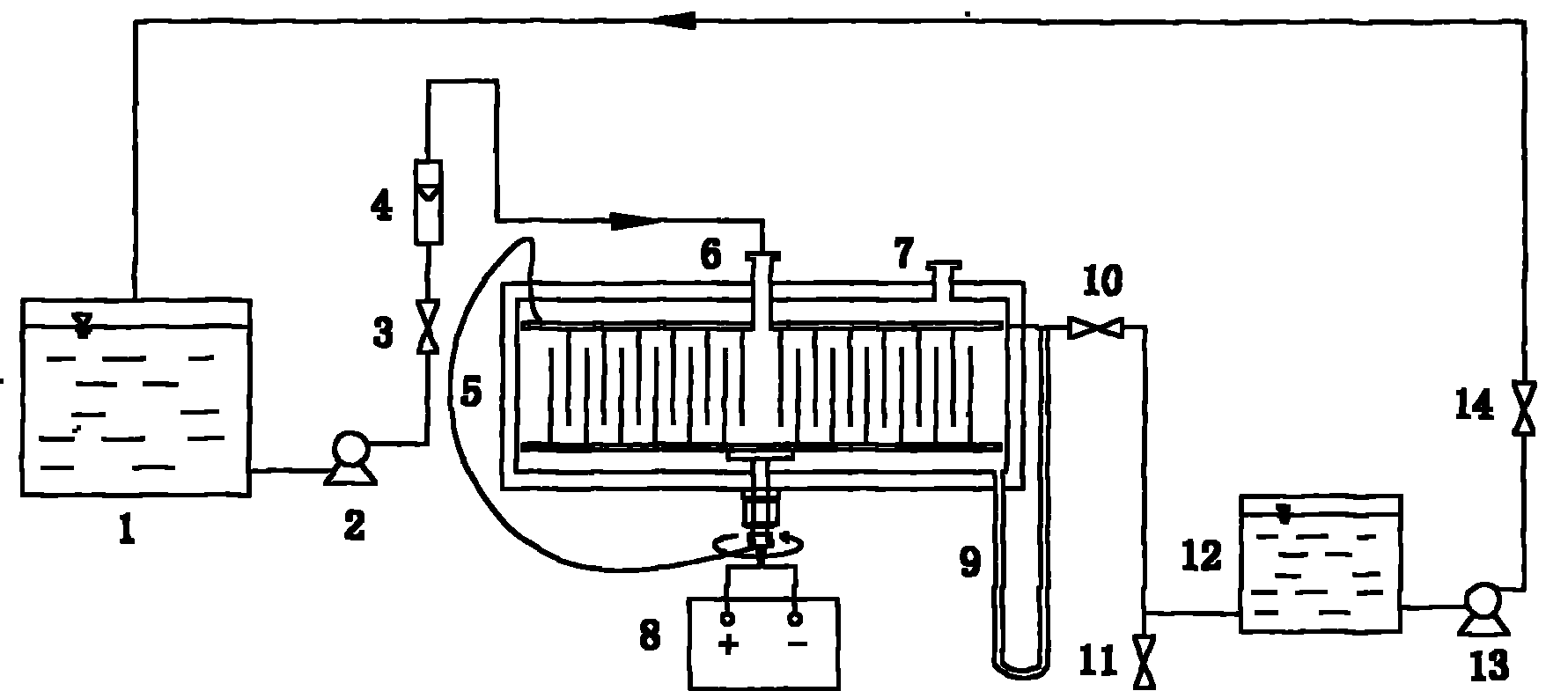

[0017] The continuous operation supergravity multi-stage concentric cylindrical electrolytic reaction device includes: an electrolytic reaction device composed of an anode disk 5.3, a cylindrical anode 5.4, a cathode disk 5.6 and a cylindrical cathode 5.7, a DC stabilized power supply or an electrochemical reaction control (device ) system; during the electrolysis process, the electrolyte continuously enters the supergravity multi-stage concentric cylindrical electrolysis reaction device 5, the cathode disk 5.6 is in a static state, and the anode disk 5.3 rotates at a high speed driven by the central rotating shaft 5.2, and the electrolyte is subjected to the supergravity effect, An electrolytic reaction occurs. Among them, the cylindrical anode 5.4 and the cylindrical cathode 5.7 are arranged concentrically and alternately, the distance between the cylindrical cathode 5.7 and the anode disk 5.3 is equal to the distance between the cylindrical anode 5.4 and the cathode disk 5.6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com