Intelligent negative pulse repairing charger

A charger and negative pulse technology, applied in the field of intelligent negative pulse repair chargers, can solve the problems of not meeting the needs of battery buyers, lack of a resting stage in the charging process, lack of negative pulse activation, etc. Compact, well-designed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Reference attached Figure 1~3 , The intelligent negative pulse repair charger has a charger shell 1, a mains input plug 2, a charging output interface 3, a digital display window 6 and a light-emitting diode indicator 4. The light-emitting diode indicator 4 carries out red and green positive and negative pulse indications.

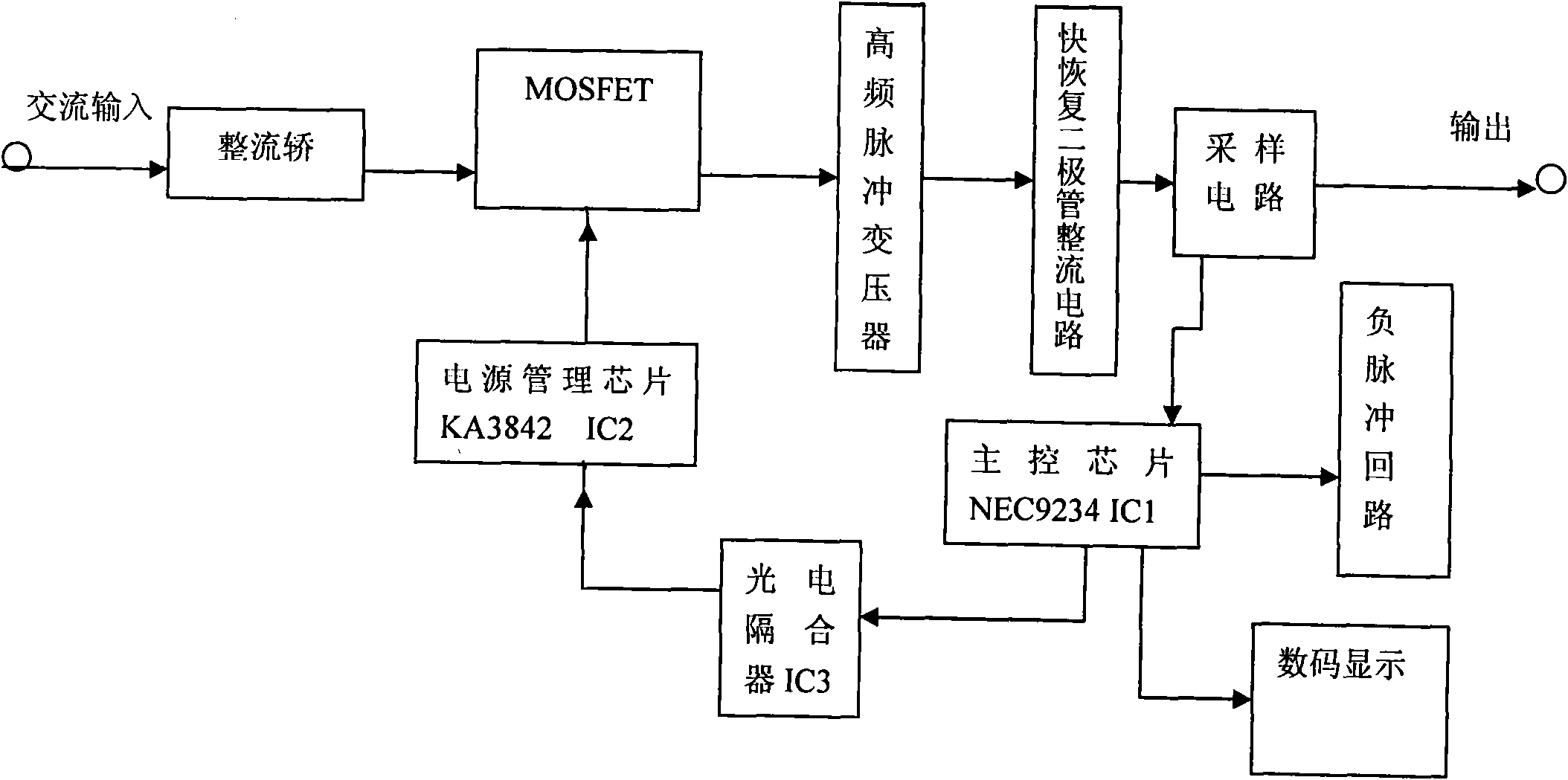

[0027] The charger shell 1 contains electronic circuit boards, electronic circuits and electronic components. The electronic circuits include rectifier bridge, MOSFET tube (field effect tube), main control chip (microcontroller) IC1, power management chip IC2, photoelectric isolator IC3, High frequency pulse transformer, fast recovery diode rectifier circuit, sampling circuit, negative pulse circuit, digital display.

[0028] The input end of the rectifier bridge is connected to the AC power supply, the output end of the rectifier is connected to the high-frequency pulse transformer through the MOSFET tube, and the output end of the high-frequency puls...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com