Anti-rotation angle tower frame foundation and manufacturing method

An angle tower, anti-rotation technology, applied in basic structure engineering, construction and other directions, can solve the problems of high construction cost and long construction time, and achieve the effect of small footprint, convenient installation and construction, and scientific design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

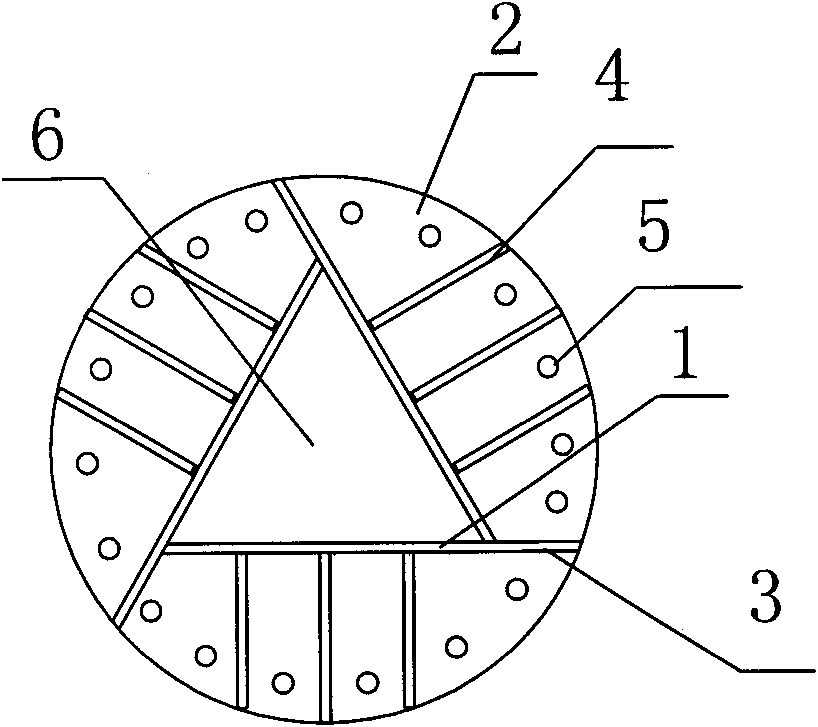

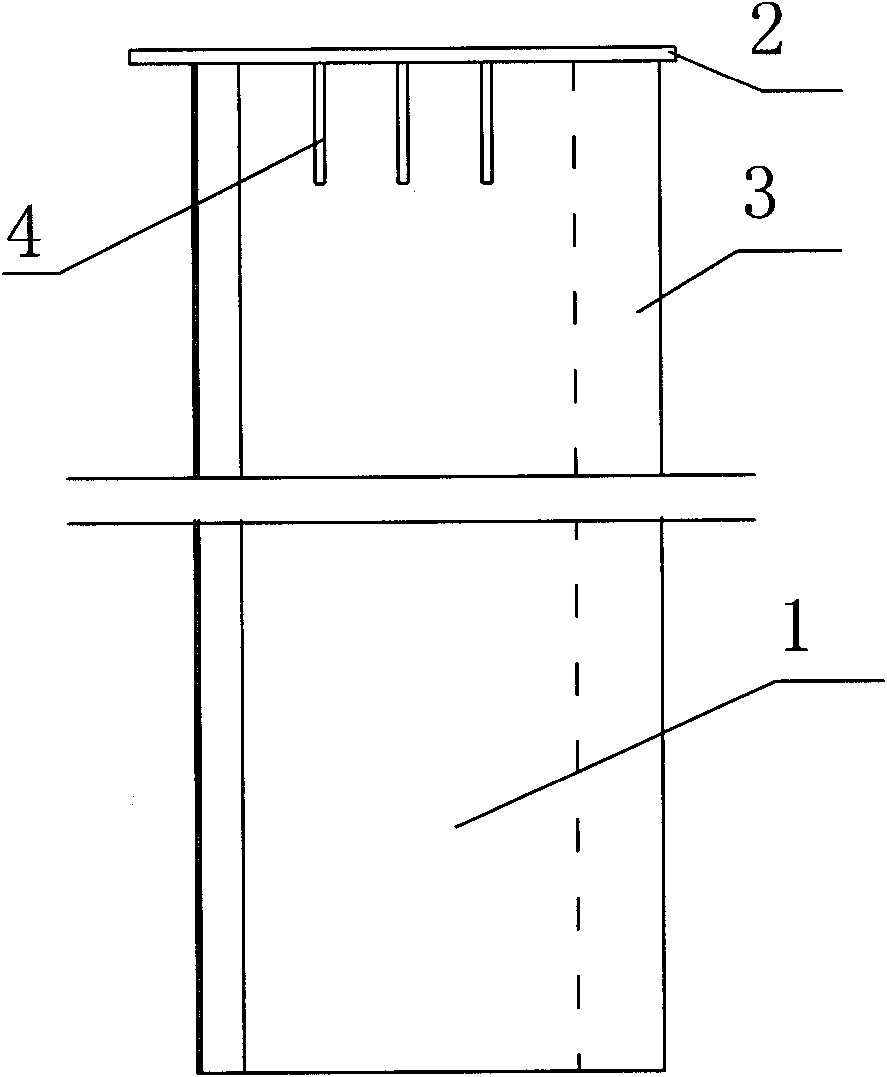

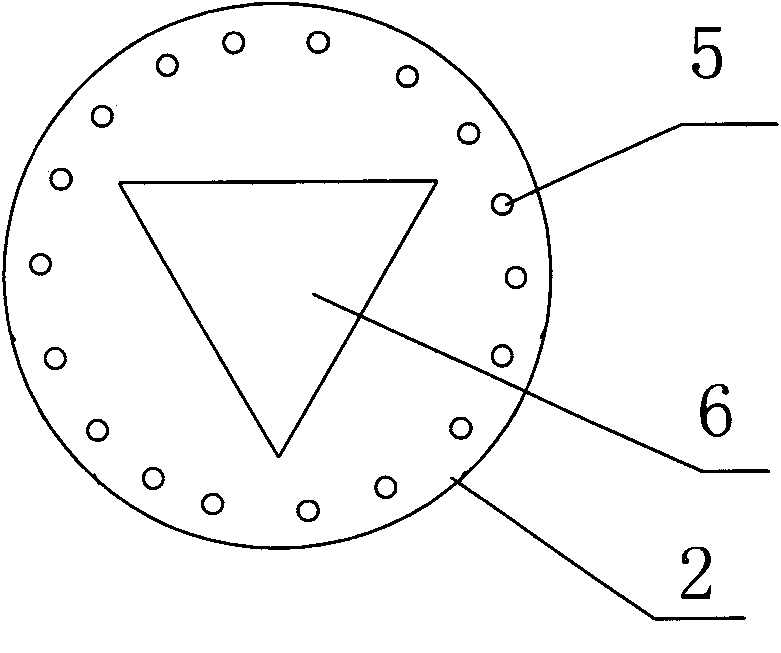

[0026] It consists of a flange connecting the tower body and an anti-rotation structure. Firstly, the thickness, height, and width of the steel plate of the main body of the foundation are designed according to the force of the foundation of the corner tower (the side length of the hollow regular triangular prism plus the length of the triangular prism extended from the side of the prism) The width of the anti-rotation plate), the three main steel plates are welded in sequence during welding, and three anti-rotation wing plates of equal width are reserved. The flange plate connecting the tower body is welded on both sides with the end of the steel plate of the main body. Three rib plates are added to each side of the main body of the regular triangular prism. One side of the rib is welded to the flange plate on both sides, and the other side is double-sided to the outer wall of the pipe root. welding. After the overall welding is completed, both sides are derusted and coated w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com