Recycled concrete member with additive and method for preparing same

A technology of recycled concrete and admixtures, applied in infrastructure engineering, sustainable waste treatment, solid waste management, etc., can solve the problems of low strength of ordinary recycled concrete components, achieve the effect of improving contact interface, enhancing strength and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solutions of the present invention will be further described below in conjunction with specific embodiments.

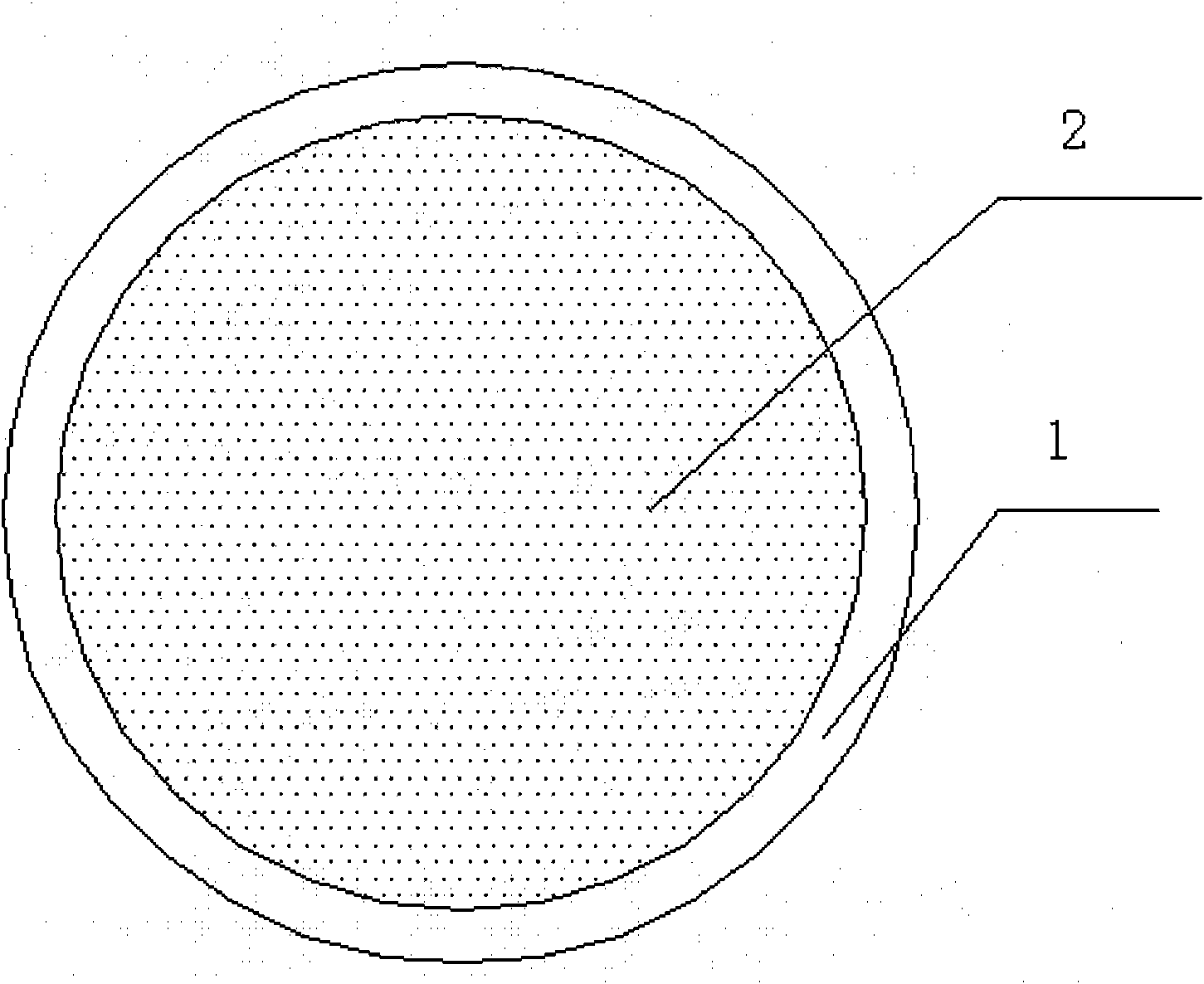

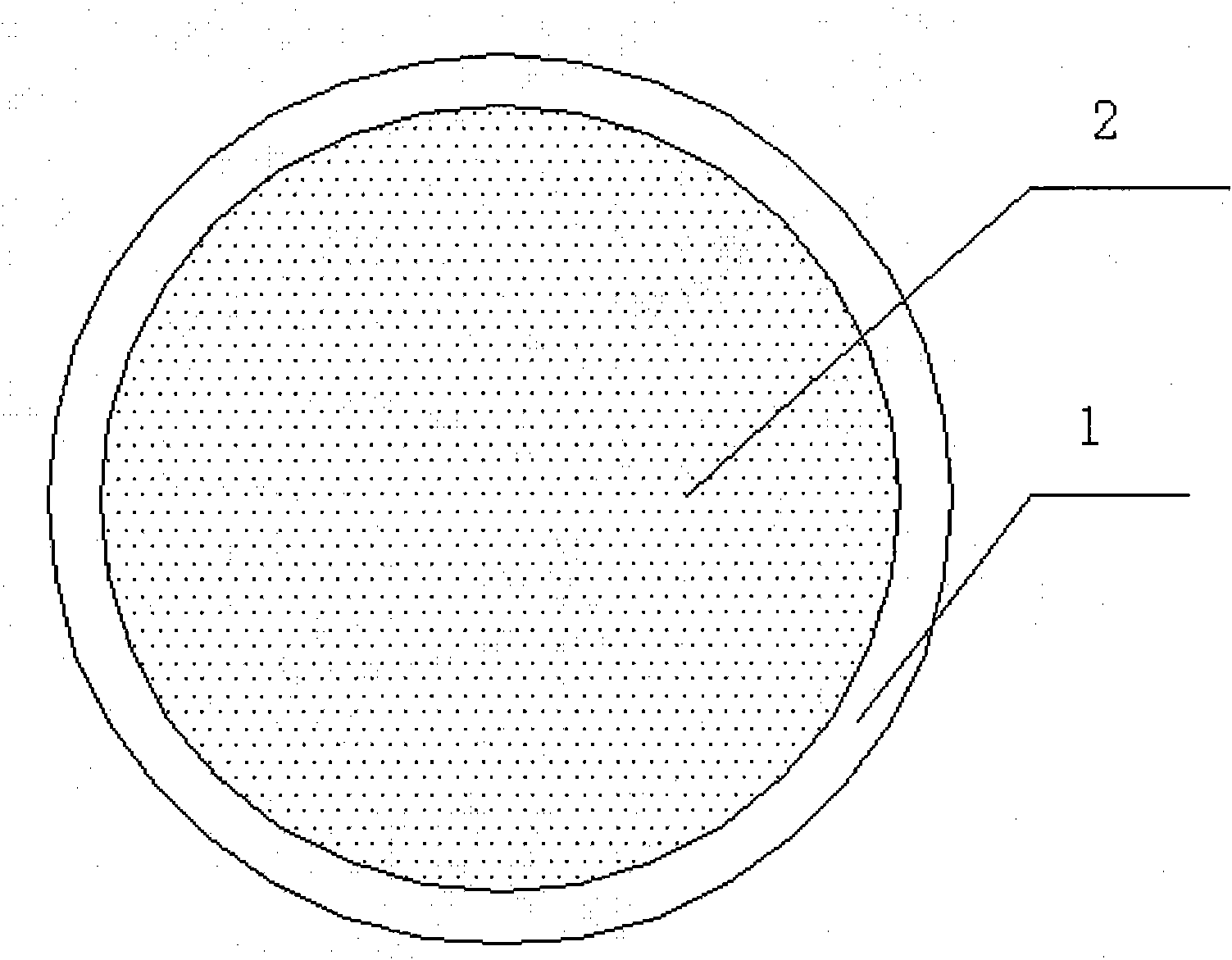

[0019] Such as figure 1 As shown, the specific implementation mode of the present invention is: build a kind of recycled concrete member, comprise cement, water, the admixture that can release carbon dioxide and the concrete aggregate that forms after the crushing of waste concrete, cement, water, can release carbon dioxide The admixture and the concrete aggregate formed by crushing waste concrete are mixed in proportion to form recycled concrete 2, and also includes a columnar matrix 1 for containing the recycled concrete, and the recycled concrete 2 is poured into the columnar matrix 1 Formed to form recycled concrete elements. In the present invention, because contain a large amount of calcium hydroxide (chemical formula is Ca(OH) in the recycled concrete 2 2 ), the regenerated concrete 2 is placed under normal mixing and normal pressure afte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com