Chip surface contact glass packaging rectifier tube and manufacturing method thereof

A technology of glass encapsulation and surface contact, which is applied in semiconductor/solid-state device manufacturing, electrical components, electric solid-state devices, etc. It can solve the problems of high current impact resistance, high cost, and large contact surface, and achieve good current impact resistance, The effect of low raw material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

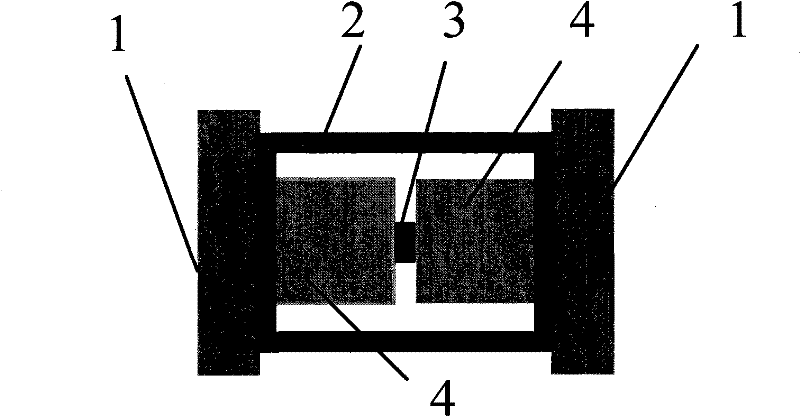

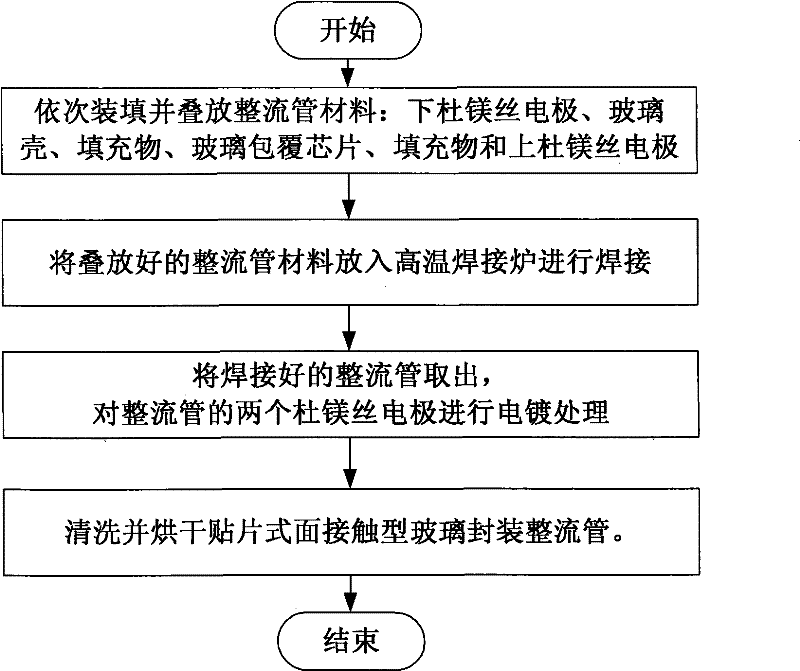

[0016] Embodiment: A patch-type surface-contact type glass-encapsulated rectifier tube, including two dumages wire electrodes 1, a hollow glass shell 2, and a glass-coated chip 3, each du magnesium wire electrode 1 inserted into the glass shell One end is connected with a magnesium wire block 4, and the glass-coated chip 3 is placed in the narrow gap between the magnesium wire block 4 at the top of the two magnesium wire electrodes 1, and the glass-coated chip 3 and the magnesium wire block 4 The gap is filled with fillers to increase the electrical connection between the glass-coated chip 3 and the Du magnesium wire block 4 and increase the effective contact area between the two. The other sides of the glass-encapsulated chip 3 are completely covered by glass glue, which increases the feasibility of the body glass package.

[0017] The filler between the glass-coated chip 3 and the Du magnesium wire block 4 used in this embodiment is a high-temperature solder sheet with a mel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com