Large-torque continuous rotating type SMA motor

A rotating disk, unidirectional rotation technology, applied in the direction of generator/motor, piezoelectric effect/electrostrictive or magnetostrictive motor, electrical components, etc., can solve the problems of low heating efficiency and small output torque, etc. To achieve the effect of simple and effective heating method, large output torque and high heating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

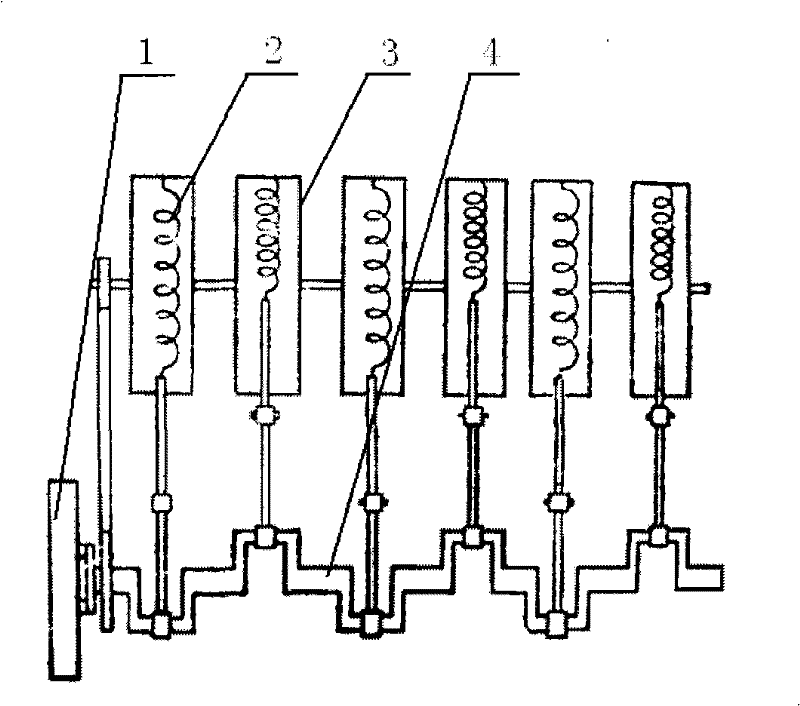

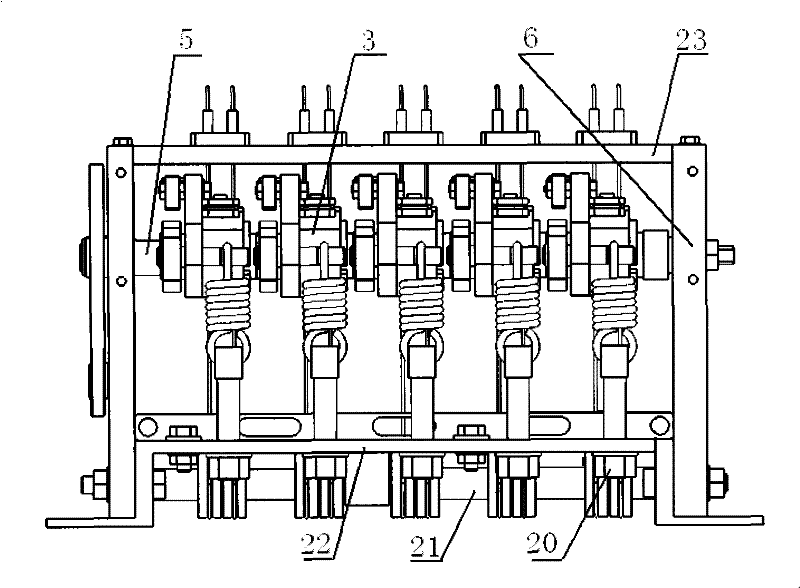

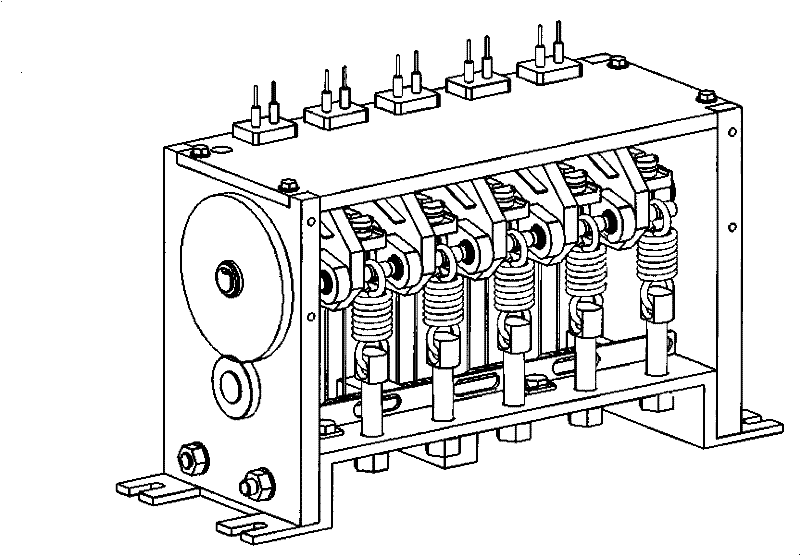

[0038] For the application of the present invention, the "shape memory characteristic" of SMA (shape memory alloy) material refers to: the material is stretched and deformed at a certain low temperature, and its deformation cannot be fully restored after unloading, leaving residual deformation. However, as long as it is heated to a higher temperature, the residual deformation disappears and returns to the original unstretched shape, which is manifested as "memorizing the shape at a lower temperature", and a large amount of force is generated during the recovery process. Resilience.

[0039] In engineering, SMA wires and springs are usually combined to form a driving element, that is, the SMA wires and springs are connected to each other through a certain stretching deformation. Until the spring force is balanced with the yield force of the SMA wire and the output load; when the temperature rises, the SMA wire shrinks, and the restoring force of the SMA wire overcomes the spring ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com