Method for gasifying solid fuel and concurrent gasifier

A technology of gasification fuel and solid fuel, which is applied in gasification process, biofuel, manufacture of combustible gas, etc., to reduce the risk of fire

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

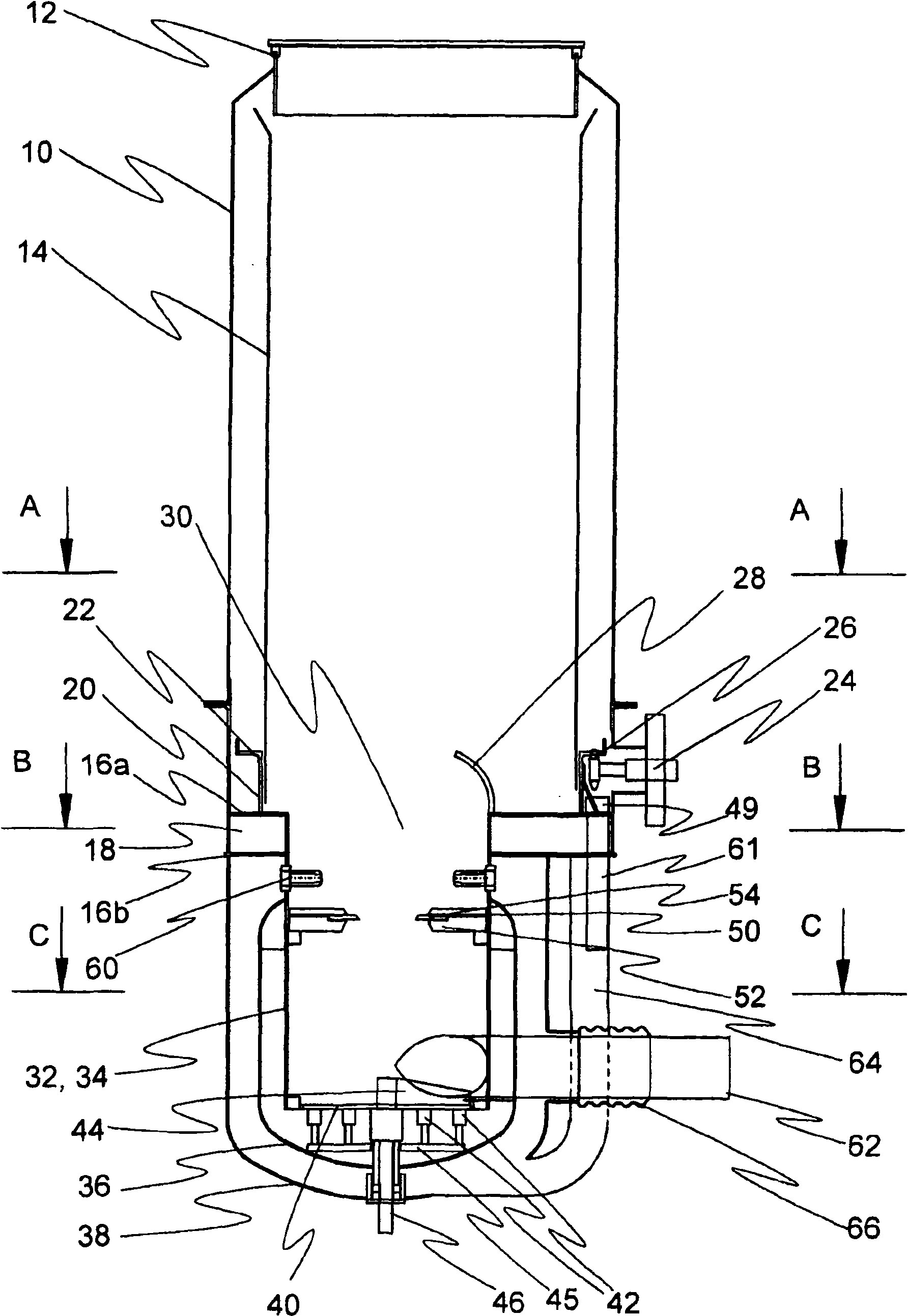

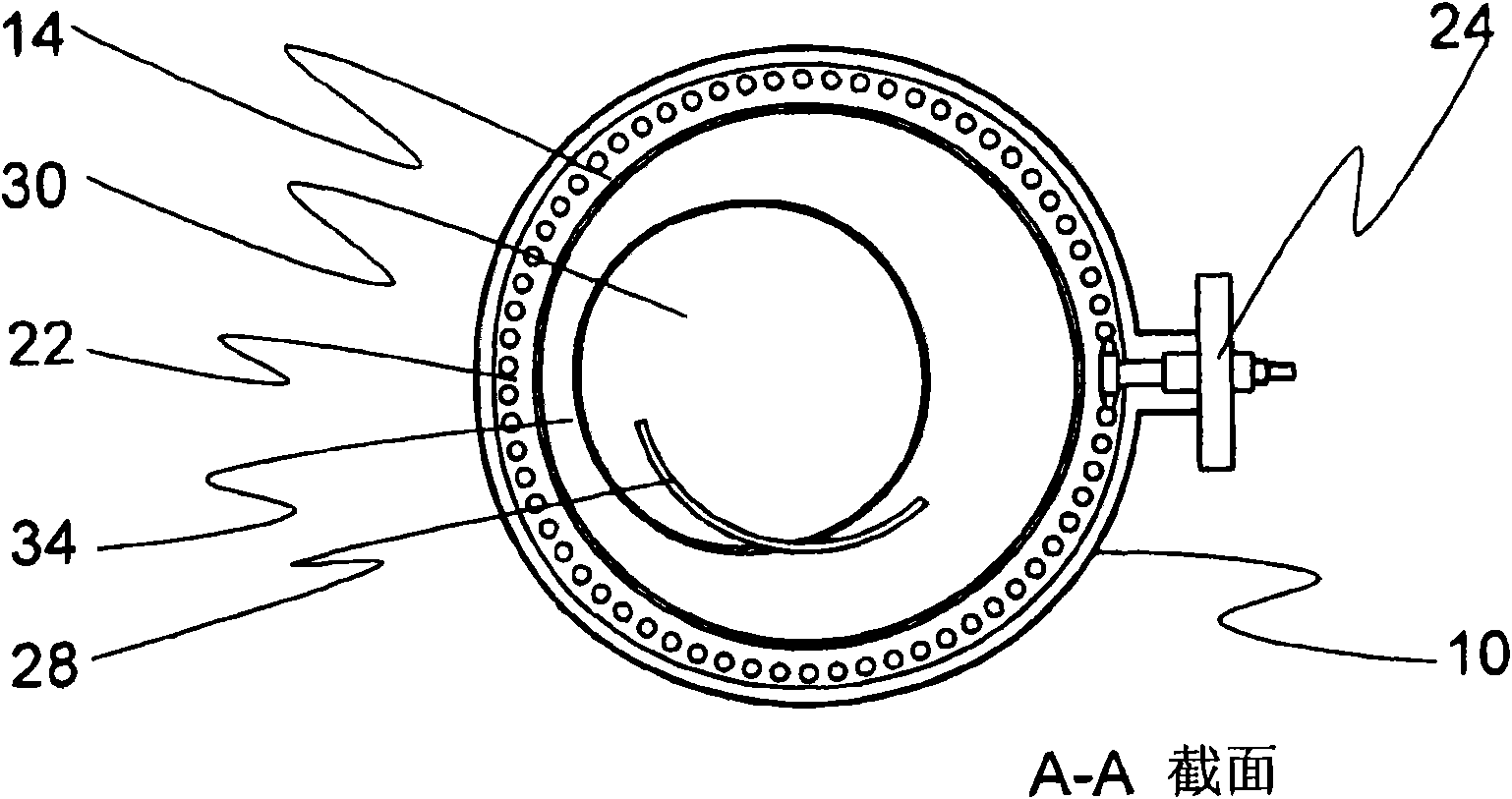

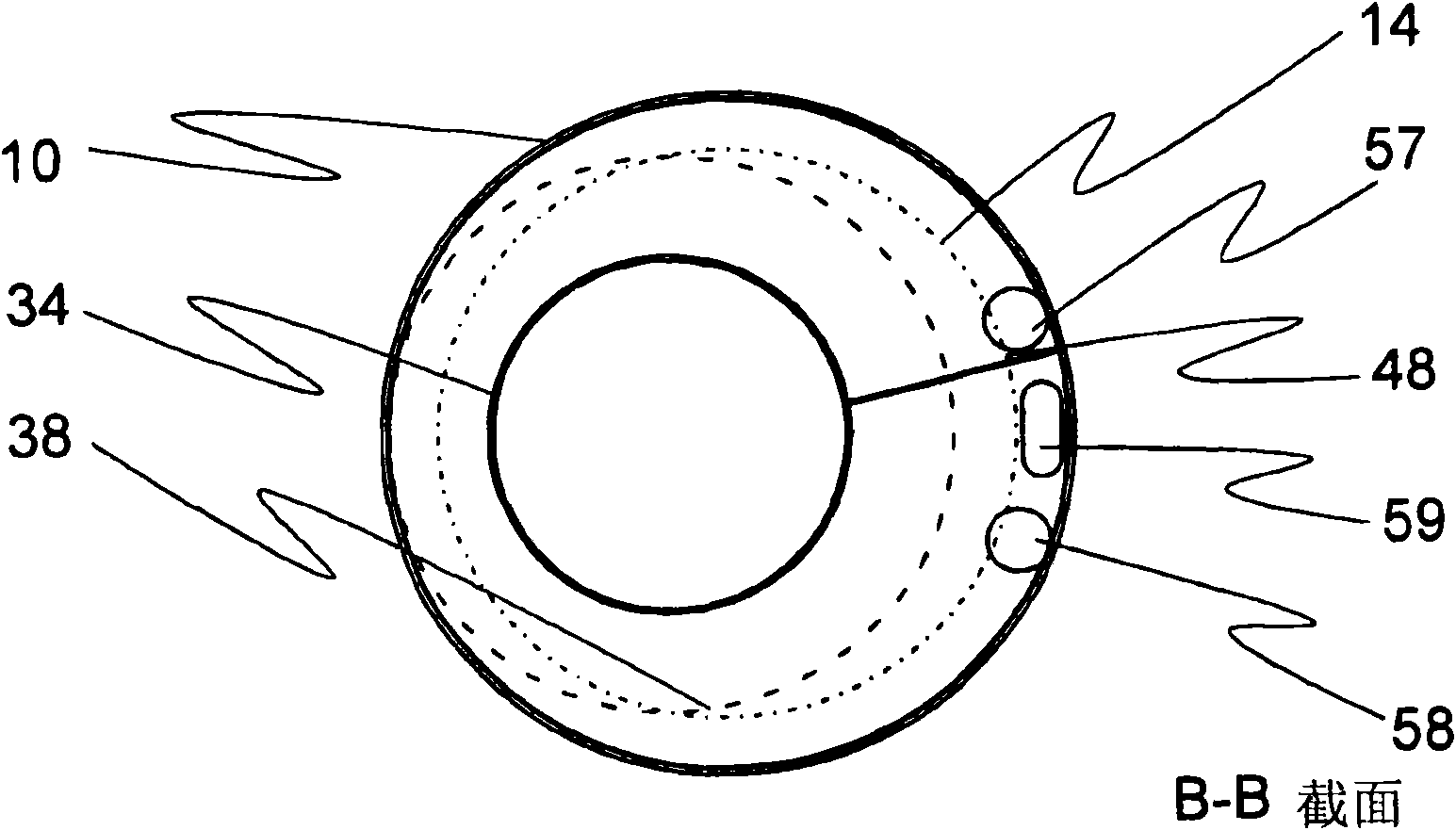

[0023] exist figure 1 In , an example of a gasification generator according to the invention is shown as a vertical section. Figure 2a to Figure 2c Shown as a horizontal section viewed along section heights A-A, B-B and C-C figure 1 vaporizer. In use, the co-flow vaporizer is at figure 1 vertical position shown. Directional expressions such as up, down, above, below, upper surface and lower surface used in this specification indicate when the gasifier is in figure 1 orientation in the vertical position shown. If the vaporizer is at a different figure 1 For some other positions than those shown, the directional expression changes accordingly.

[0024] The gasifier has a cylindrical casing 10 and on its upwardly directed end there is a gas-tight, openable cap 12 . as a basis figure 1 Instead of the cap, the gasifier may also have some other cap structure that enables automatic fueling. In the outer cover, there are two substantially parallel base plates at a certain di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com