Guy cable rod type one-dimensional stretching arm

A technology of stretching arms and cable rods, which is applied to aerospace equipment, aerospace vehicles, aircraft, etc., can solve the problems of limited structural strength, large mass, and difficulty in achieving precise positioning, and achieve simple device structure, large ratio, and small mass effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

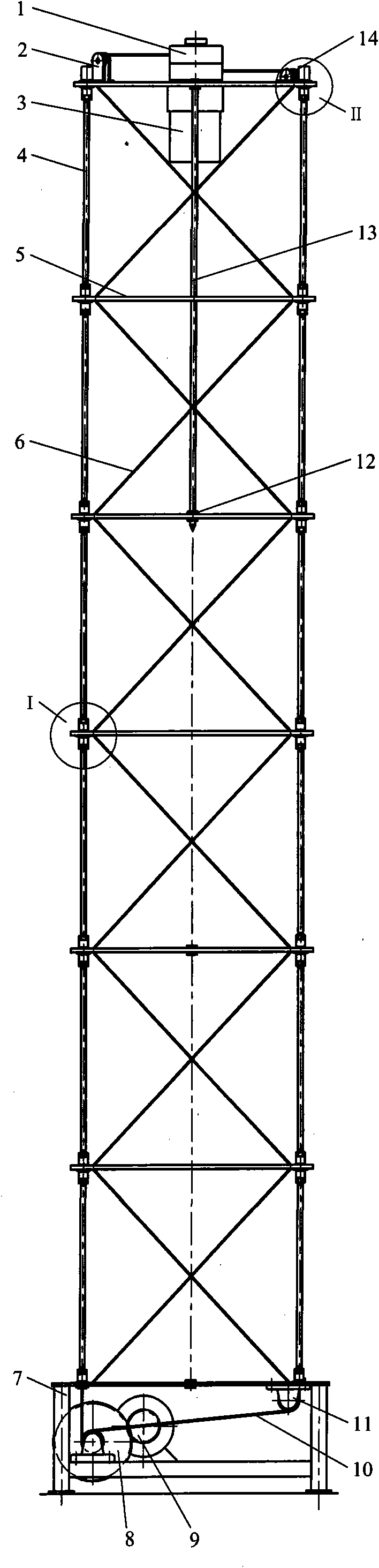

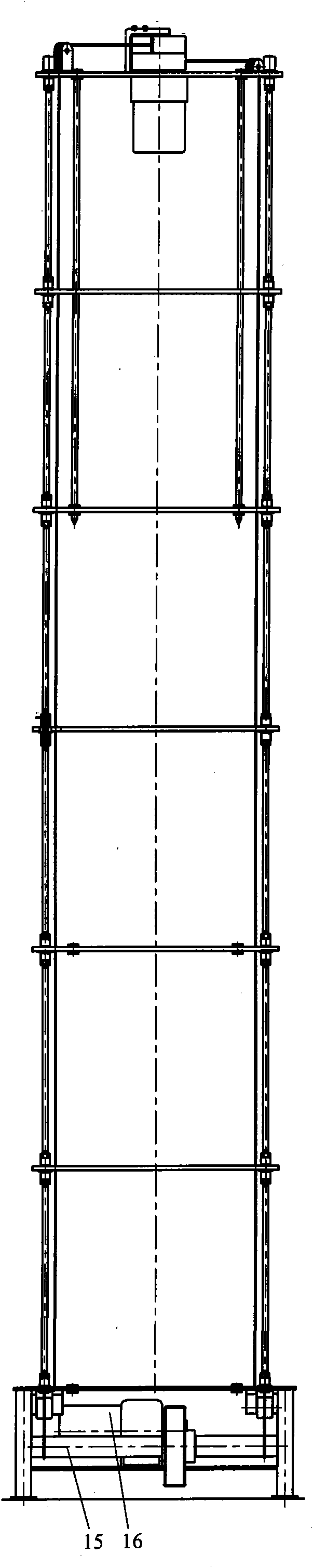

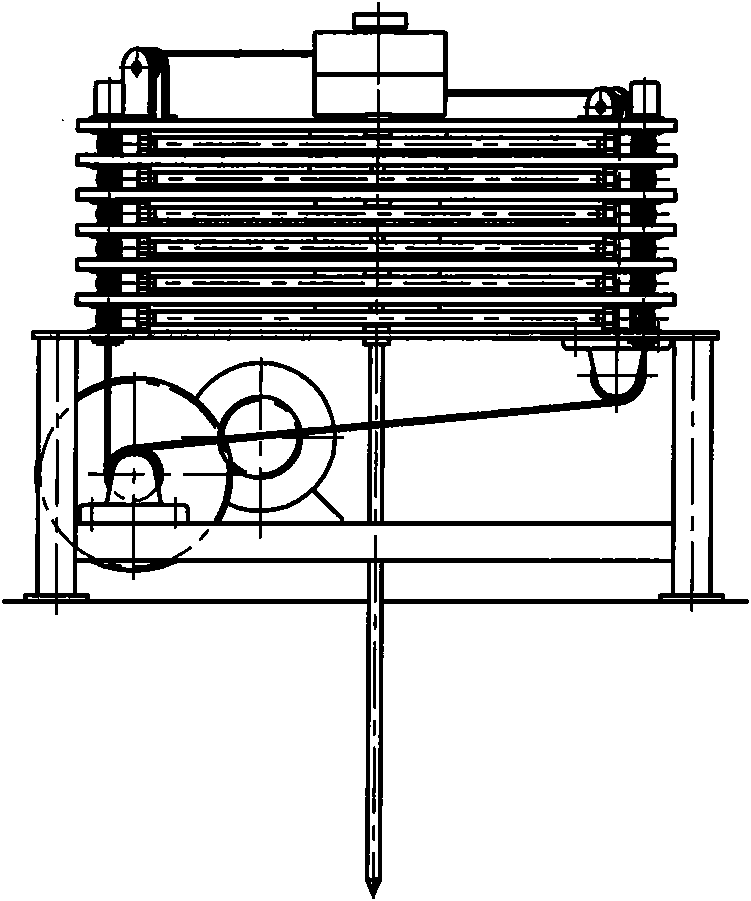

[0027] The cable rod type one-dimensional extension arm consists of a set of extension mechanisms, the extension mechanism is composed of four hollow support rods 4 and two rigid frames 5, and the extension cable 10 passes through the support rods 4 Hollow and fixed on the turning taper sleeve 23 of rigid frame 5 corners, one end is fixed on the top of stretching mechanism, and the other end is fixed on the stretching roller 15 that is connected with stretching arm seat 7 by rotating pair, described stretching roller 15 and stretching The motor 16 is connected, and the pulling cables 6 pass through the diagonal apertures of the rigid frame 5 respectively, and one end is fixed on the extension arm seat, the other end is fixed on the pulling roller 1, and two anti-rotation rods 13 are fixed on the On the topmost rigid frame mentioned above, and form a moving pair with the linear bearings fixed on the rigid frame of the next layer, starting from the top layer, linear bearings 12 a...

Embodiment 2

[0029] The said cable rod type one-dimensional extension arm, the said rigid frame is a square frame, the four corners are respectively equipped with flip taper sleeves and drilled with four small holes, and the hollow support rod is locked by the flip cone 17. The nut 18 is fixedly connected with the hollow rod 19 to form. The unfolding motor 16 is connected with the unfolding roller 15 through a pinion 9 and a bull gear 8 .

Embodiment 3

[0031] For the cable rod type one-dimensional extension arm, when the extension mechanism is in the unfolded state, the adjacent small holes through which the same pulling cable passes are located on the two sides of the same side of the extending arm, and the pulling cable is in the shape of " Z" shape; when the stretching mechanism is folded, the small hole passed by the same pull cable is on the same axis, and the pull cable is straightened; driven by the pull motor, the pull roller can be tightened and loosened by reversing forward and backward The retracting cable is driven by the unfolding motor, and the forward and reverse rotation of the unfolding roller can tighten and relax the unfolding cable.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com