Method for preparing basalt fiber cloth-filled ultra high-speed impact protective structure material

A basalt fiber cloth, ultra-high-speed impact technology, used in fiber processing, aerospace safety/emergency devices, textiles and papermaking, etc., can solve problems such as high cost, poor impact damage protection, and difficult to buy Kevlar and Nextel , to achieve the effect of high crushing projectile ability, high consumption projectile impact energy ability, excellent thermal insulation and electrical insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0012] Specific Embodiment 1: The preparation method of basalt fiber cloth filled ultra-high-speed impact protection structural material in this embodiment is realized according to the following steps: 1. Spray glue on basalt fiber cloth, and then dry it; 2. Arrange the dried basalt fiber in Whipple In the protective structure, the basalt fiber cloth is obtained to fill the ultra-high-speed impact protective structure material; in the first step, the type of glue sprayed is neoprene, epoxy resin glue or liquid sodium silicate.

[0013] In the first step of this embodiment, glue spraying treatment is to spray a layer of glue on the basalt fiber cloth.

[0014] The type of glue sprayed in step 1 of this embodiment adopts neoprene or liquid sodium silicate, both of which are finished glue sold on the market; epoxy resin glue needs to be prepared on site, using 618# epoxy resin, adding 8% of the mass of epoxy resin % to 10% of curing agent and 20% to 30% of epoxy resin mass plasti...

specific Embodiment approach 2

[0022] Embodiment 2: This embodiment differs from Embodiment 1 in that the basalt fiber cloth in step 1 is a two-dimensional or three-dimensional fabric woven from basalt fiber yarns. Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0023] Specific Embodiment Three: This Embodiment The preparation method of the basalt fiber cloth filled ultra-high-speed impact protection structural material in this embodiment is realized according to the following steps: 1. The basalt fiber cloth is sprayed with glue, and then dried; 2. The dried basalt fiber Arranged in the Whipple protective structure, the basalt fiber cloth filled ultra-high-speed impact protective structural material is obtained; the glue used in the first step is epoxy resin glue.

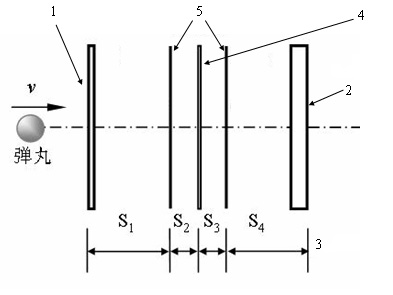

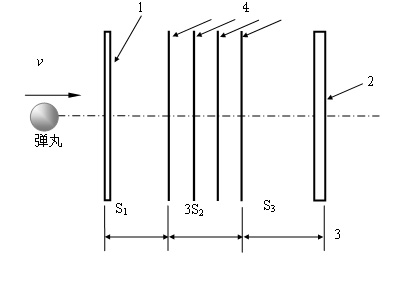

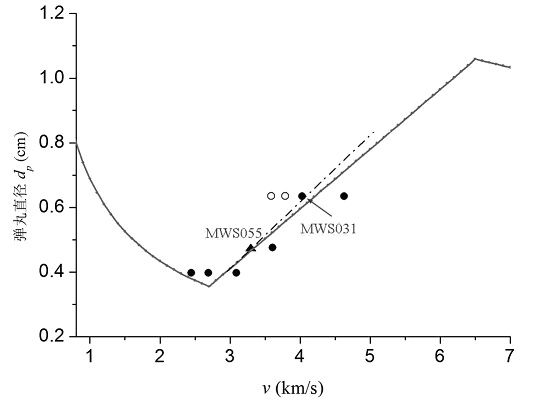

[0024] The basalt fiber cloth obtained in this embodiment is filled with ultra-high-speed impact protection structural materials such as figure 1 As shown, it is composed of aluminum protective screen, aluminum bulkhead plate, thin aluminum plate and basalt fiber cloth, in which the aluminum protective screen 1 is an aluminum alloy plate of 1-2 mm, and the aluminum bulkhead plate 2 is an aluminum alloy plate of 3-5 mm. The aluminum plate 3 is an aluminum alloy plate of 0....

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com