Pilot-operated type endless rope winch for coal mines

A non-polar rope winch and hydraulic control technology, which is applied in hoisting devices and clockwork mechanisms, etc., can solve the problems of high performance requirements of the reduction box, large damage to the planetary gear, and reduced work efficiency, so as to achieve torque balance and improve Usable performance, space-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

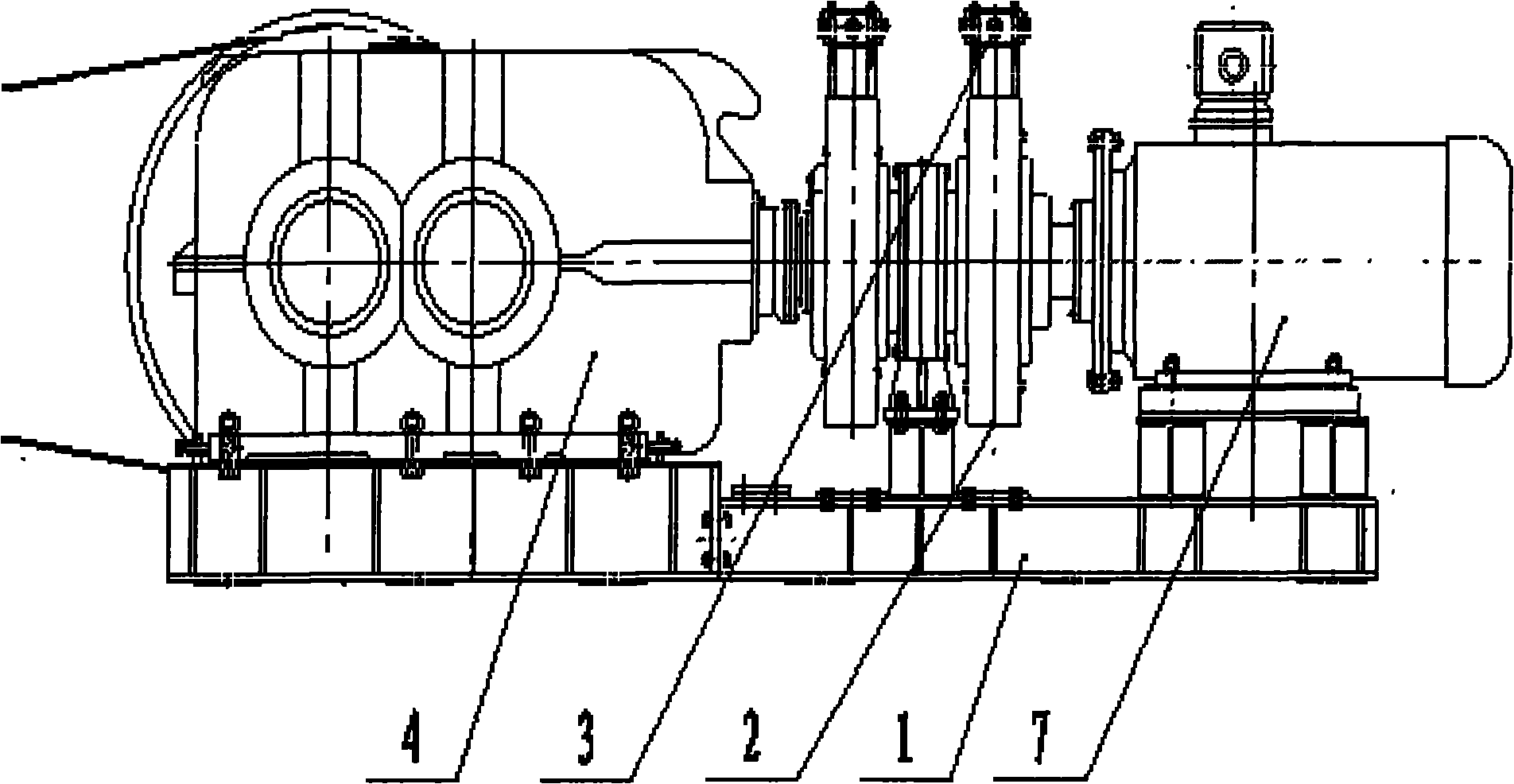

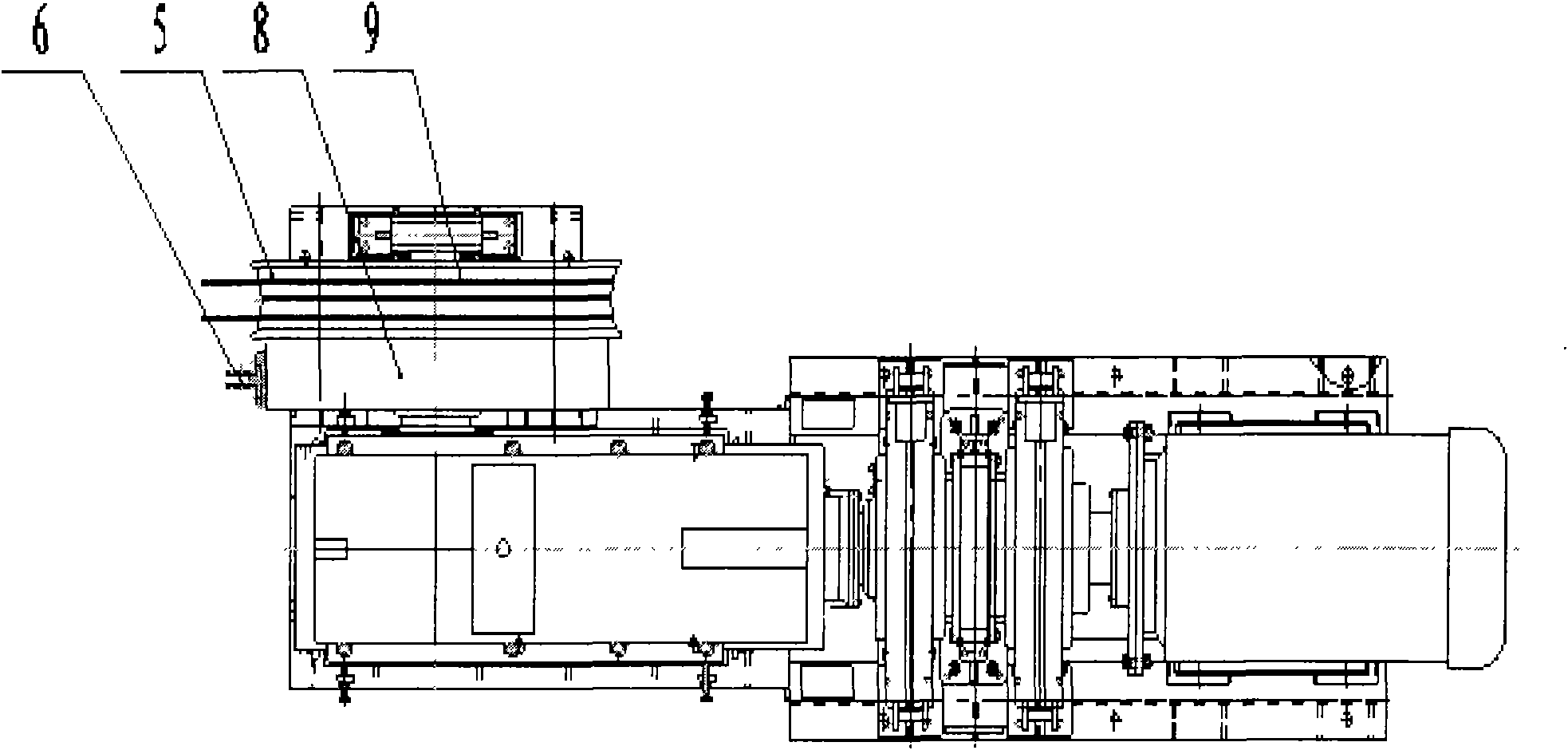

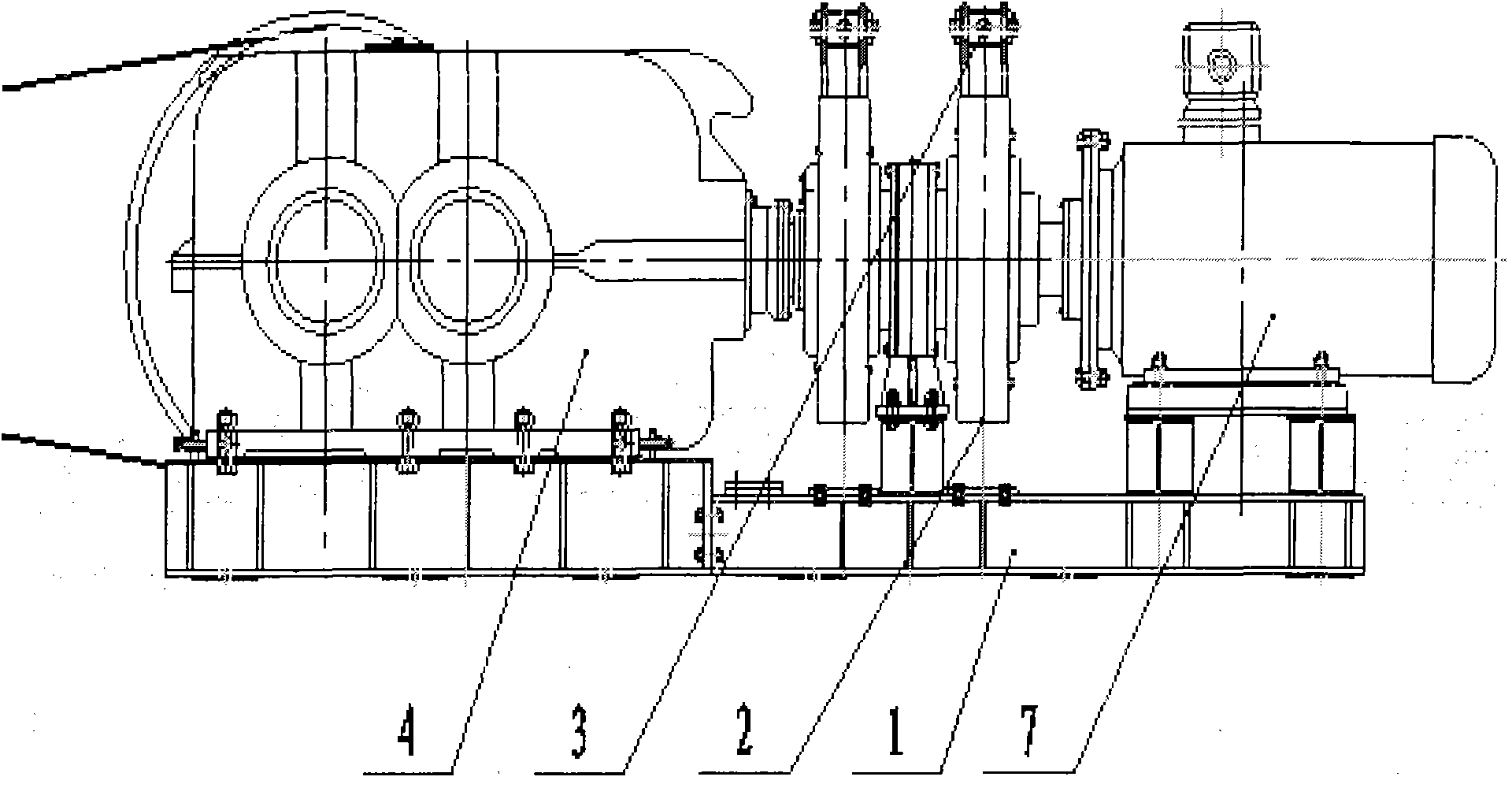

[0016] A kind of hydraulic control type endless rope winch used in coal mine in this embodiment refers to the attached Figure 1-2 , including a motor 7 for providing power to the winch, the motor 7 is connected to a planetary gear device 2, and the planetary gear device 2 is provided with a fast and slow speed gate 3 for forming zero speed, slow speed and fast speed, and the planetary gear device 2 drives A reducer 4 is connected to the reducer 4, and the drive connection of the reducer 4 is connected with a friction wheel 5 that adopts a single friction drum and is used to realize two-way rope output from the winch and realize reliable and constant tension and driving force in both forward and reverse directions. The friction wheel 5 and the system The driving wheel 8 is coaxial and directly connected, and the brake wheel 8 is equipped with a safety brake 6 that adopts a normally closed spring brake and a hydraulic brake release. The effect of safety brake 6 is to realize th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com