High-efficiency purification system of papermaking sewage

A technology for purification system and papermaking sewage, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, flocculation/sedimentation water/sewage treatment, etc. Earth and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

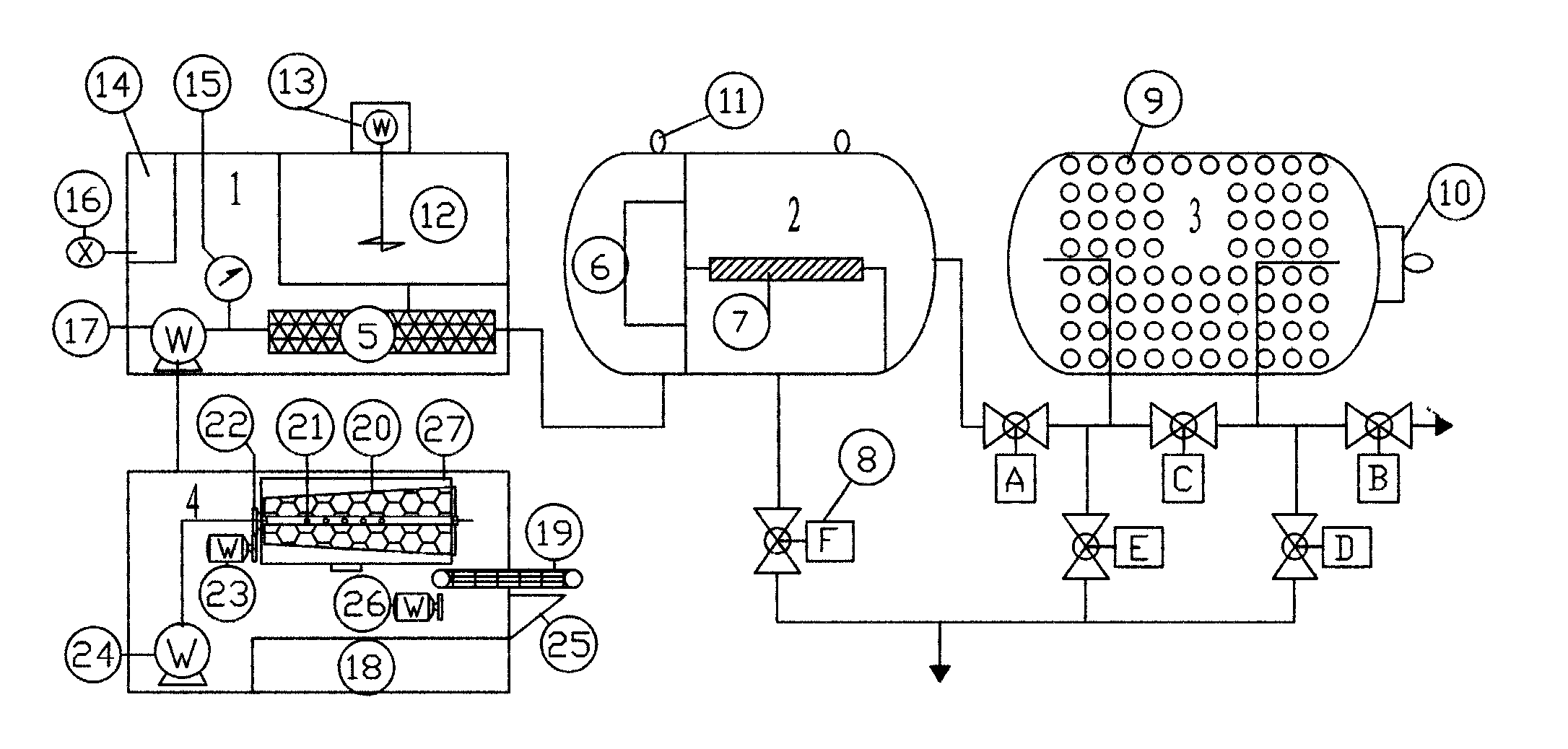

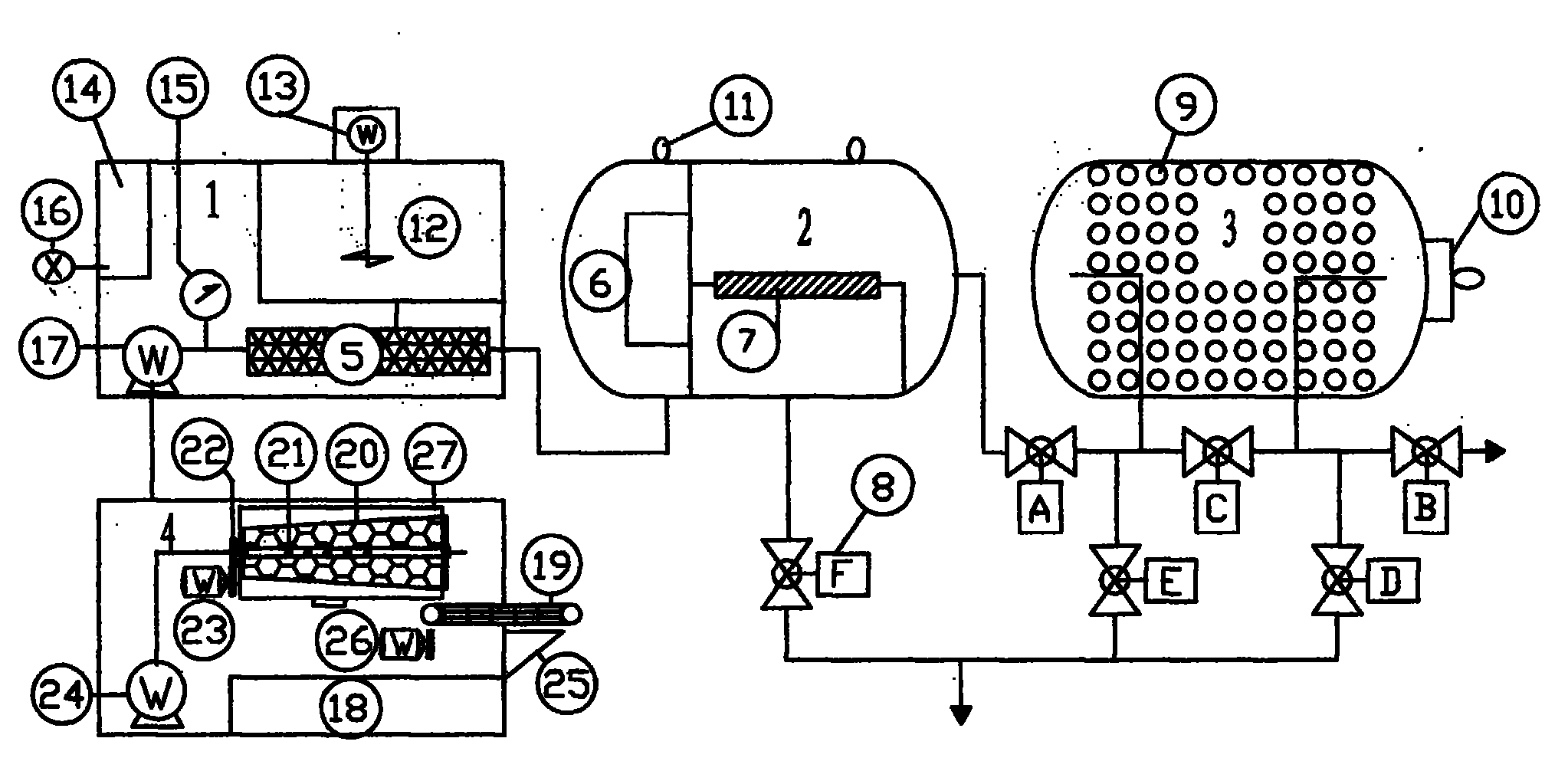

[0007] Below in conjunction with accompanying drawing, patent of the present invention is described in detail:

[0008] Such as figure 1 , as shown, the patent of the present invention consists of four major parts: comprehensive processor 1, sludge coagulator 2, separation purifier 3 and primary filter 4, as well as corresponding pipelines, valves and electric controller accessories. The comprehensive processor 1 includes: a sewage self-priming pump 17, an electric contact pressure gauge 15, a water level switch 16, an electric control device 14, a medicine storage box 12, an agitator 13, a mixer 5, and the like. The sludge coagulator 2 includes: a coagulation chamber 6, a mud-water separator 7, an exhaust valve 11, an electric sewage valve 8, and the like. The separation purifier 3 includes five sets of electric valves 8, inspection ports 10, exhaust valves 11, active ore filter material 9, water distributors and the like. The primary filter 4 includes a sewage pump 24, a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com