Method and device for online measurement of liquid holdup of rotating packed bed

A technology of rotating packed bed and liquid holdup, applied in the direction of material resistance, etc., can solve the problem of being unsuitable for measuring the rotating packed bed, and achieve the effect of comprehensively reflecting detailed characteristics and accurate data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

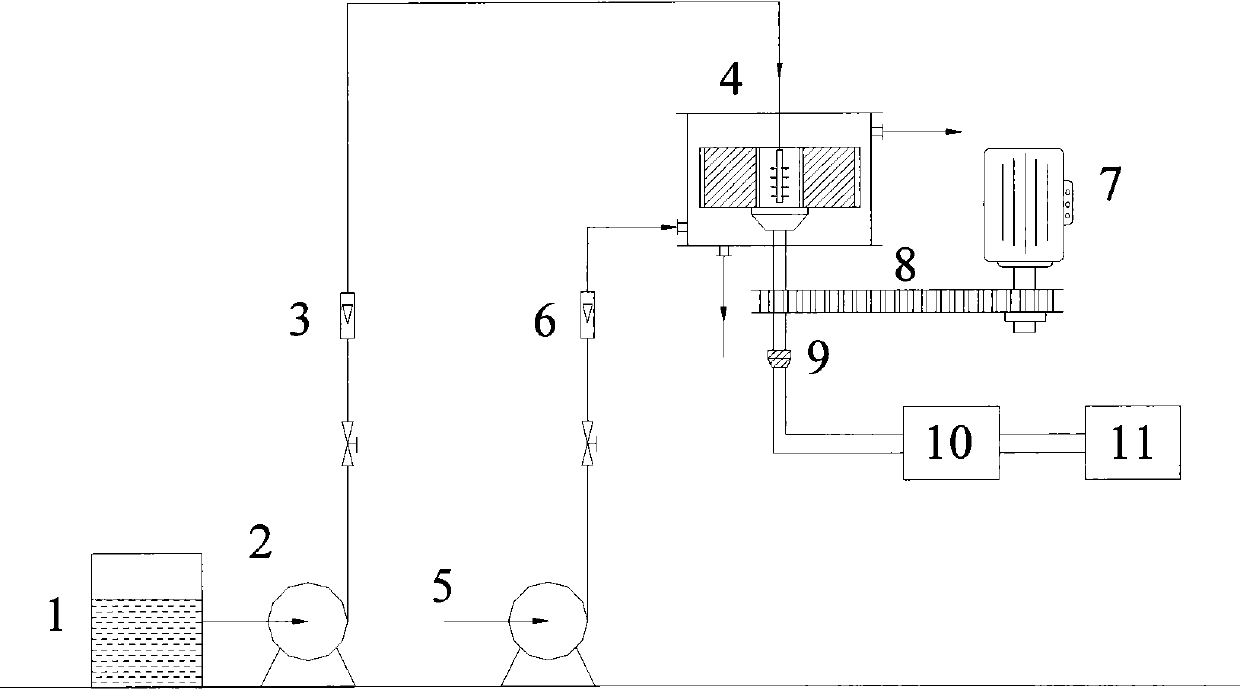

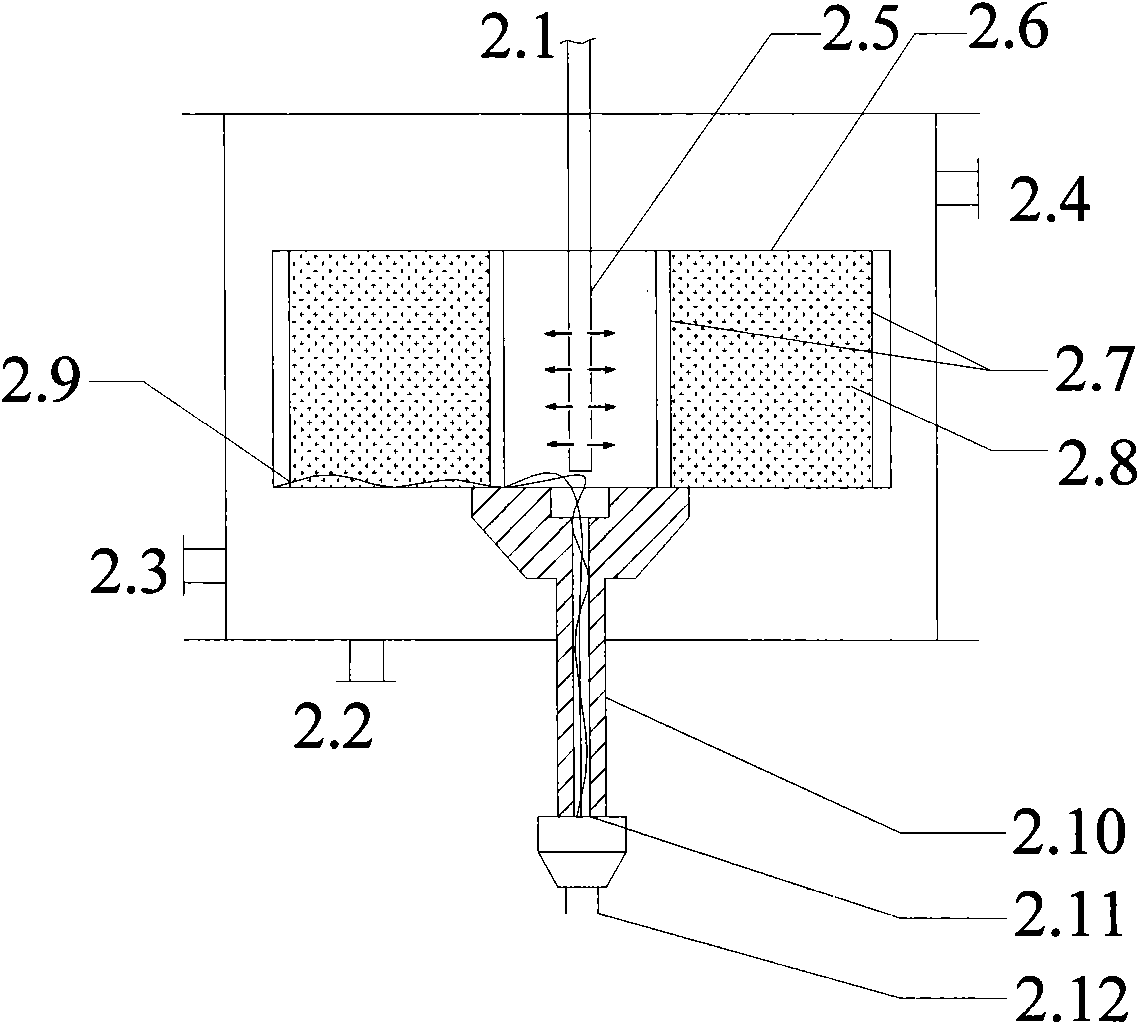

Embodiment 1

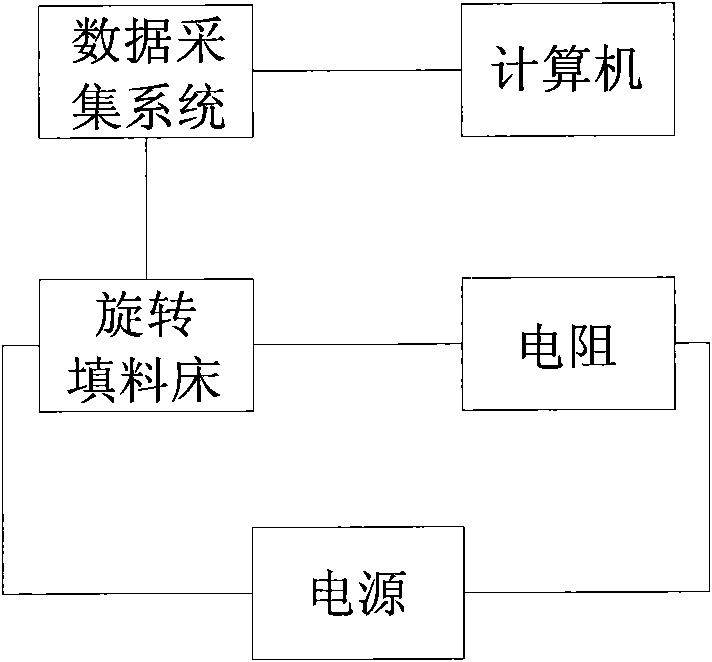

[0039] The water flow rate is fixed at 50L / h, pumped into the rotating packed bed, and sprayed evenly on the inner surface of the packing through the liquid distributor. The rotor rotates at a speed of 100rpm, and the air flow rate is 1m. 3 / h is sent to the rotating packed bed by an air compressor. The inner and outer sides of the packing are equipped with cylindrical copper wire mesh electrodes. The electrodes are connected with electric wires. The electric signals are transmitted to the outside of the rotating packed bed through the mercury slip ring through the hollow rotating shaft. The online measurement of the data acquisition system obtained an average resistance value of 13178.97Ω. From the corresponding curve of the resistance value of the standard solution and the solution volume, the liquid holding capacity in the packing was 71 mL, and the liquid holding capacity in the rotating packed bed was calculated to be 5.17%.

Embodiment 2

[0041] The water flow rate is fixed at 250L / h, pumped into the rotating packed bed, and sprayed evenly on the inner surface of the packing through a liquid distributor. The rotor rotates at 2900rpm, and the air flows at a gas flow rate of 5m. 3 / h is sent to the rotating packed bed by an air compressor. The inner and outer sides of the packing are equipped with iron perforated electrodes. The electrodes are connected with electrical wires. The wires transmit electrical signals to the outside of the rotating packed bed through a mercury slip ring through a hollow shaft. Data is collected The online measurement of the system obtains an average current value of 0.0010828A. From the corresponding curve of the resistance value of the standard solution and the amount of the solution, the liquid holding capacity in the packing is 122 mL, and the liquid holding capacity in the rotating packed bed is calculated to be 8.88%.

Embodiment 3

[0043] The water flow is fixed at 150L / h, pumped into the rotating packed bed, sprayed evenly on the inner surface of the packing through the liquid distributor, the rotor rotates at 840rpm, and the air flows at a gas flow of 10m 3 / h is sent to the rotating packed bed by an air compressor, the inner and outer sides of the packing are equipped with silver wire mesh electrodes, and the electrodes are connected with electric wires. The wires transmit electrical signals to the outside of the rotating packed bed through the mercury slip ring through the hollow shaft, and the data is collected The online measurement of the system obtains an average voltage value of 6.8201V. From the corresponding curve of the resistance value of the standard solution and the amount of the solution, the liquid holding capacity in the packing is 102 mL, and the liquid holding capacity in the rotating packed bed is calculated to be 7.43%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average resistance value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com