Tube coiling/decoiling machine and relative process

A technology of uncoiler and coil, applied in the downstream fields of rolling mills, can solve the problems of reducing output, increasing operator safety risks, increasing labor costs, etc., and achieving the effect of high productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

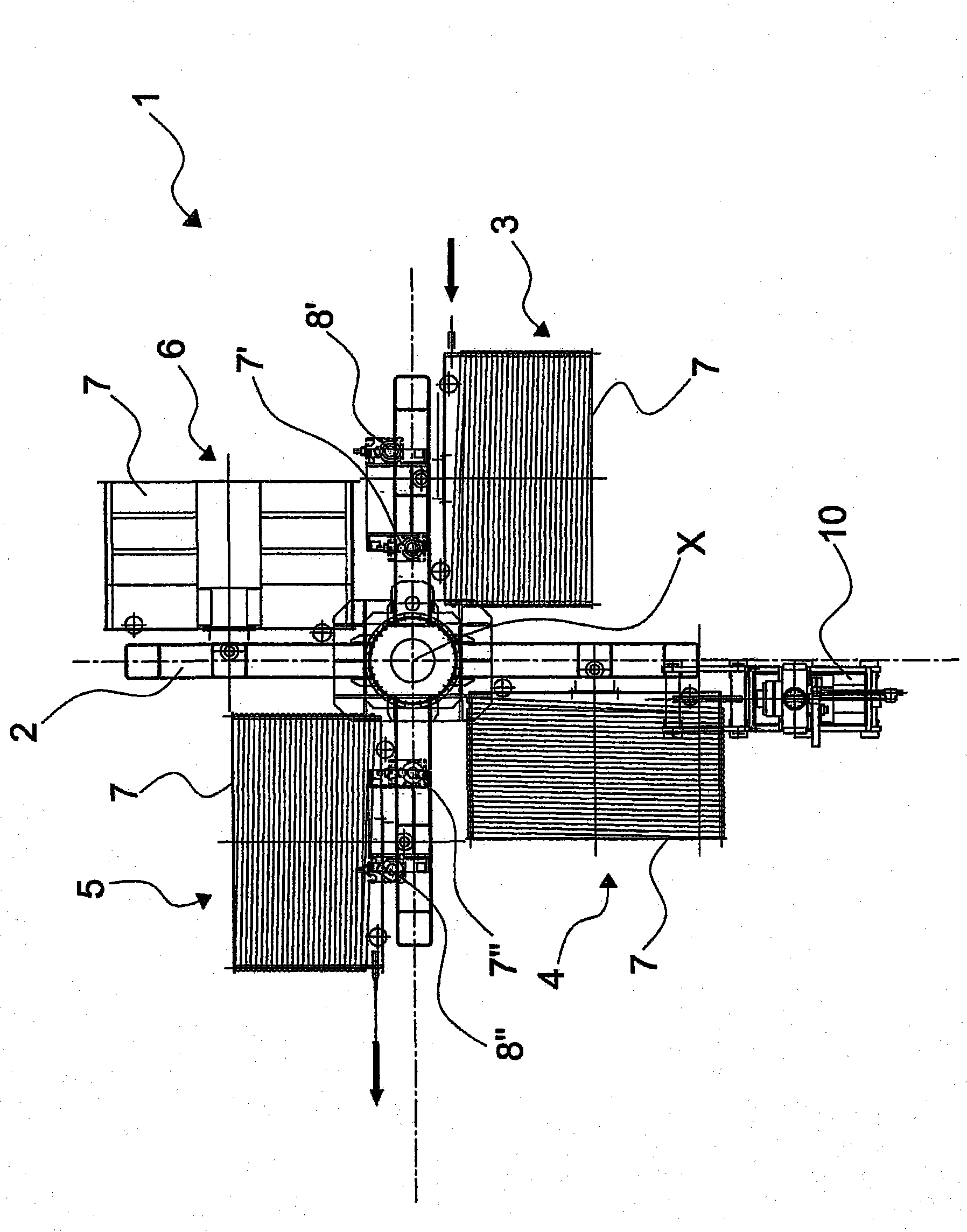

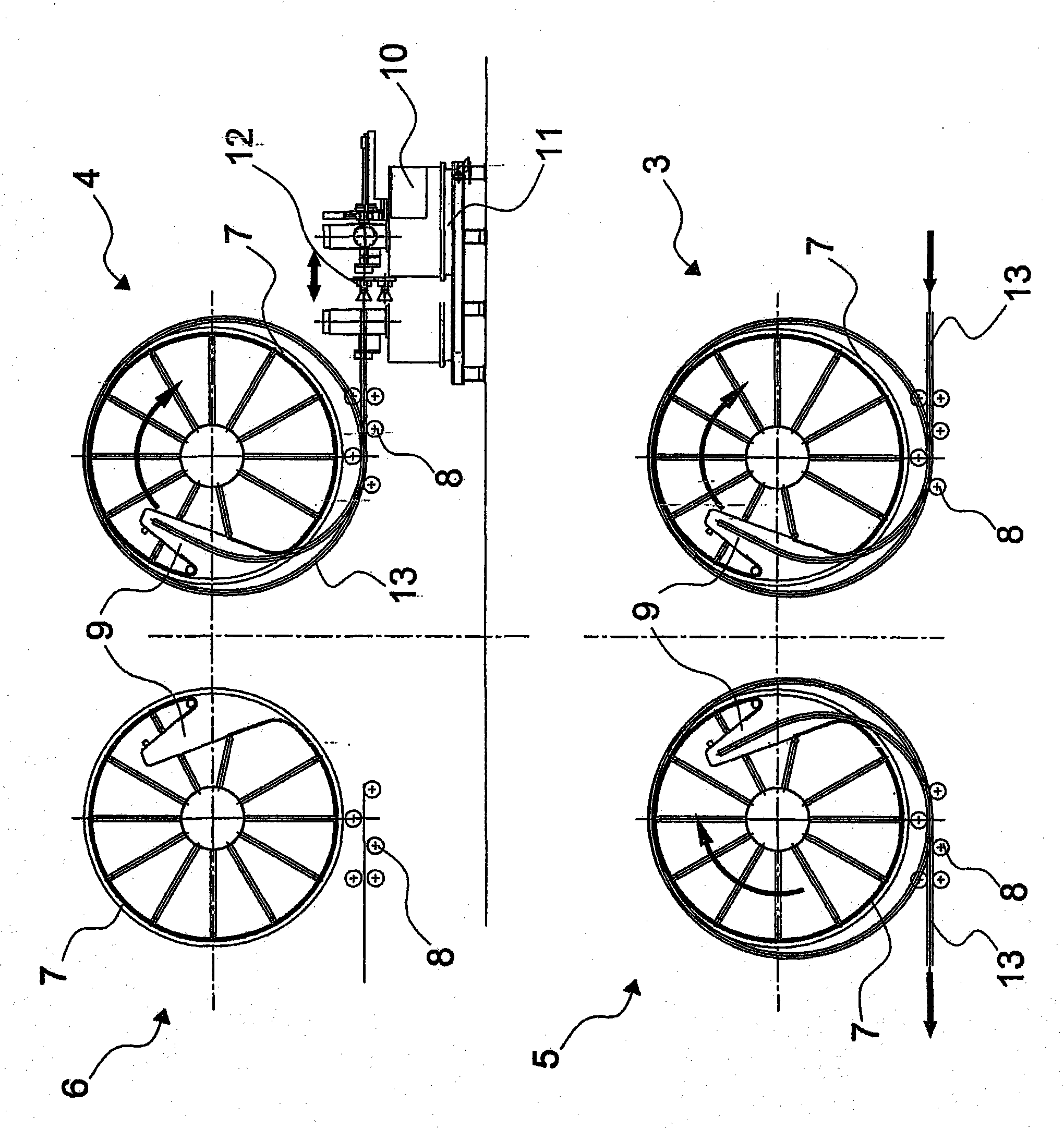

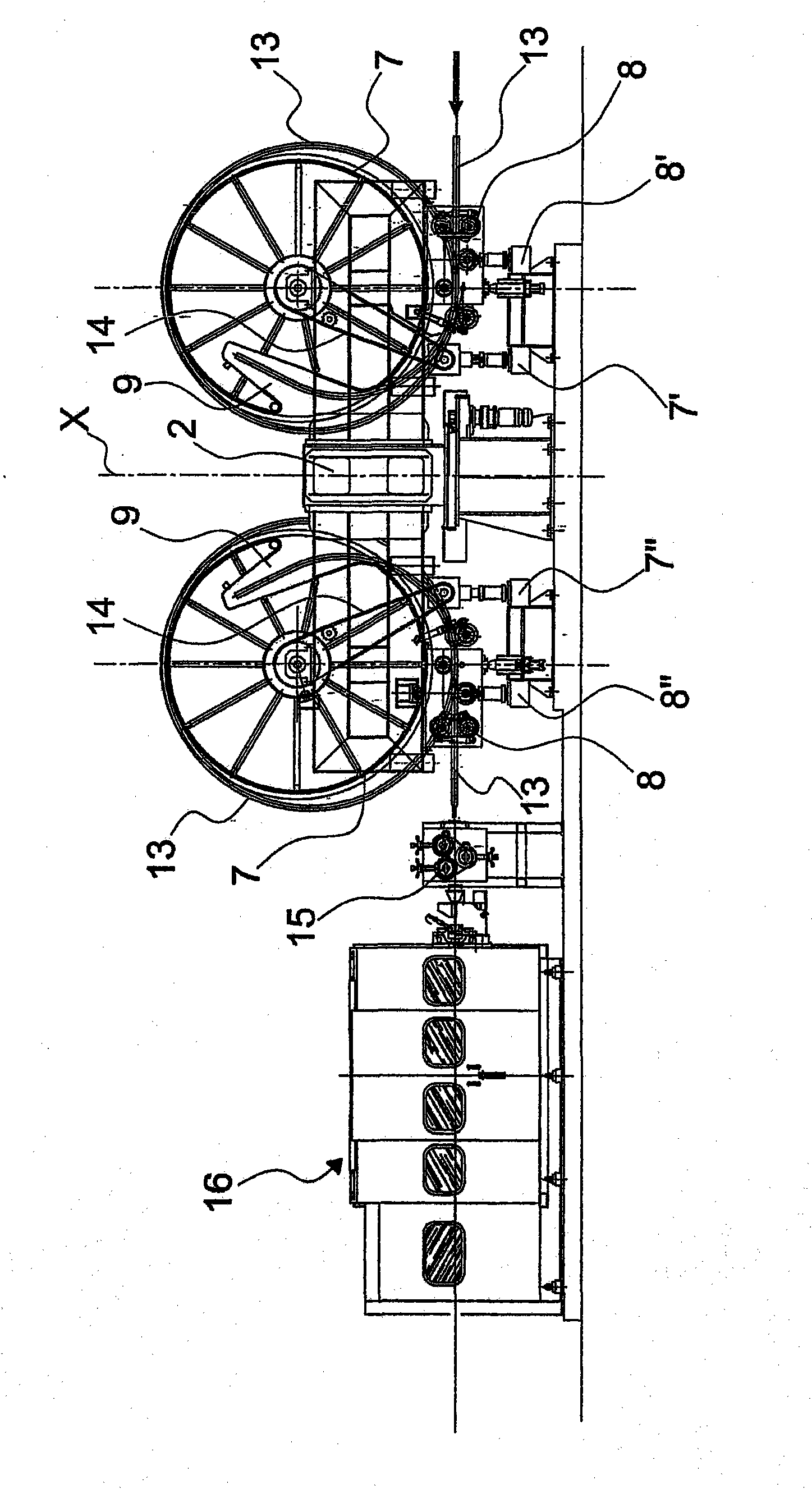

[0032] As shown in the accompanying drawings, according to the coiling / uncoiling machine of the present invention, generally marked 1, it is usually located between the rolling mill (not shown in the figure) and the downstream traction assembly for subsequent processing, and the coiling / uncoiling machine includes A cross-shaped structure 2 and a table corresponding to each arm of the cross-shaped structure.

[0033] These workbenches include:

[0034] - a coiling station 3 for forming coiled tubing;

[0035] - Taper station 4 for tapering one end of the tube;

[0036] - an uncoiling station 5 for uncoiling the conical tube coil;

[0037] - Wait for station 6.

[0038] On each arm of the cross-shaped structure 2 there is a coil support roller 7, under which bending means 8 are integrally fixed.

[0039] The cross-shaped structure 2 can be rotated 90 degrees about its X-axis direction, so that the drum 7 and the bending device 8 can be moved from one station to the other dur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com