Pneumatic tire for two-wheeled motor vehicle

A technology for motorized two-wheeled vehicles and pneumatic tires, which is applied in the direction of pneumatic tires, motor vehicles, motorcycle tires, etc., which can solve the problems of partial wear, unsatisfactory, and changes in the grounding performance of the tread rubber, and achieve enhanced rigidity and excellent performance. Drain performance, driving performance enhancement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

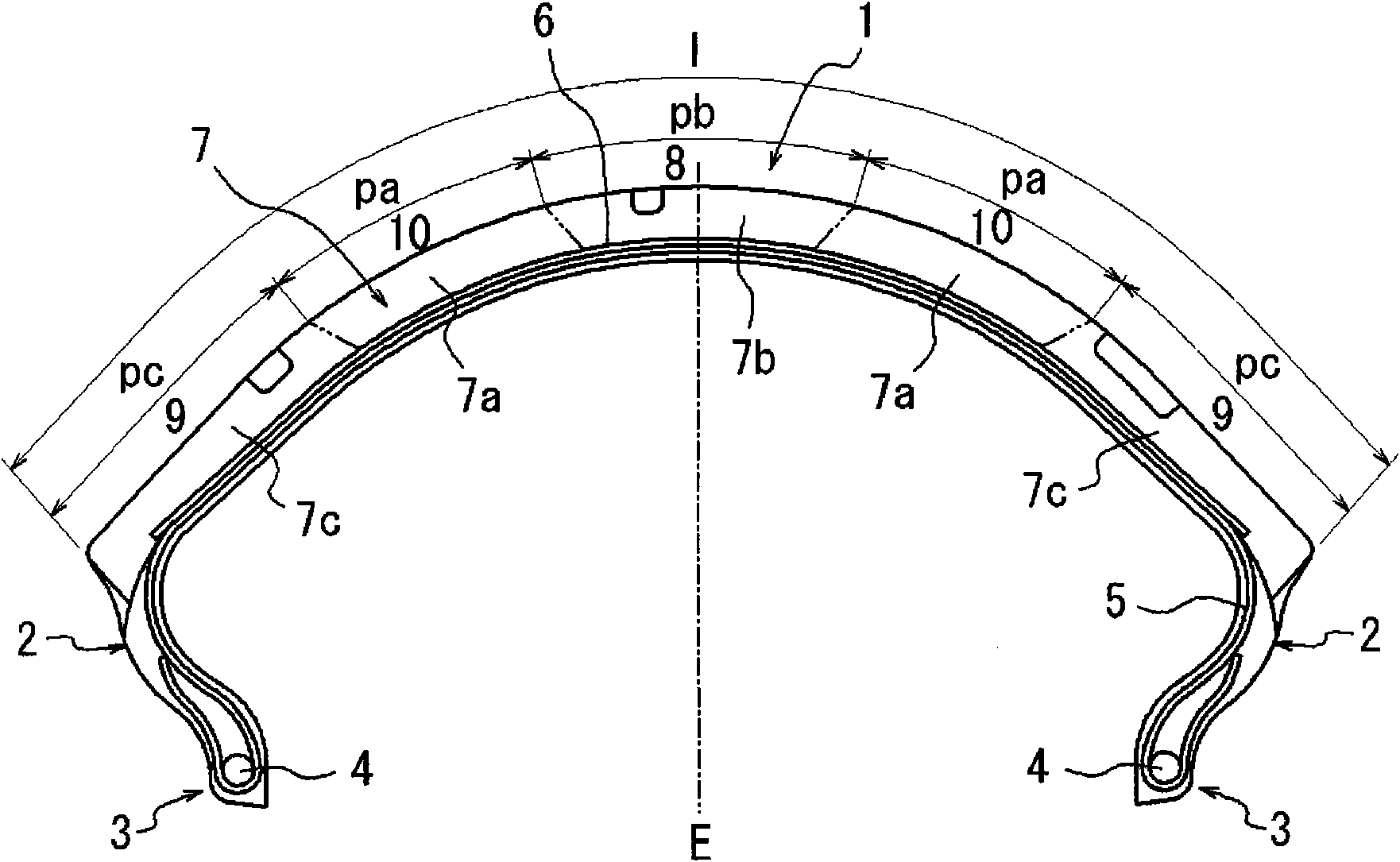

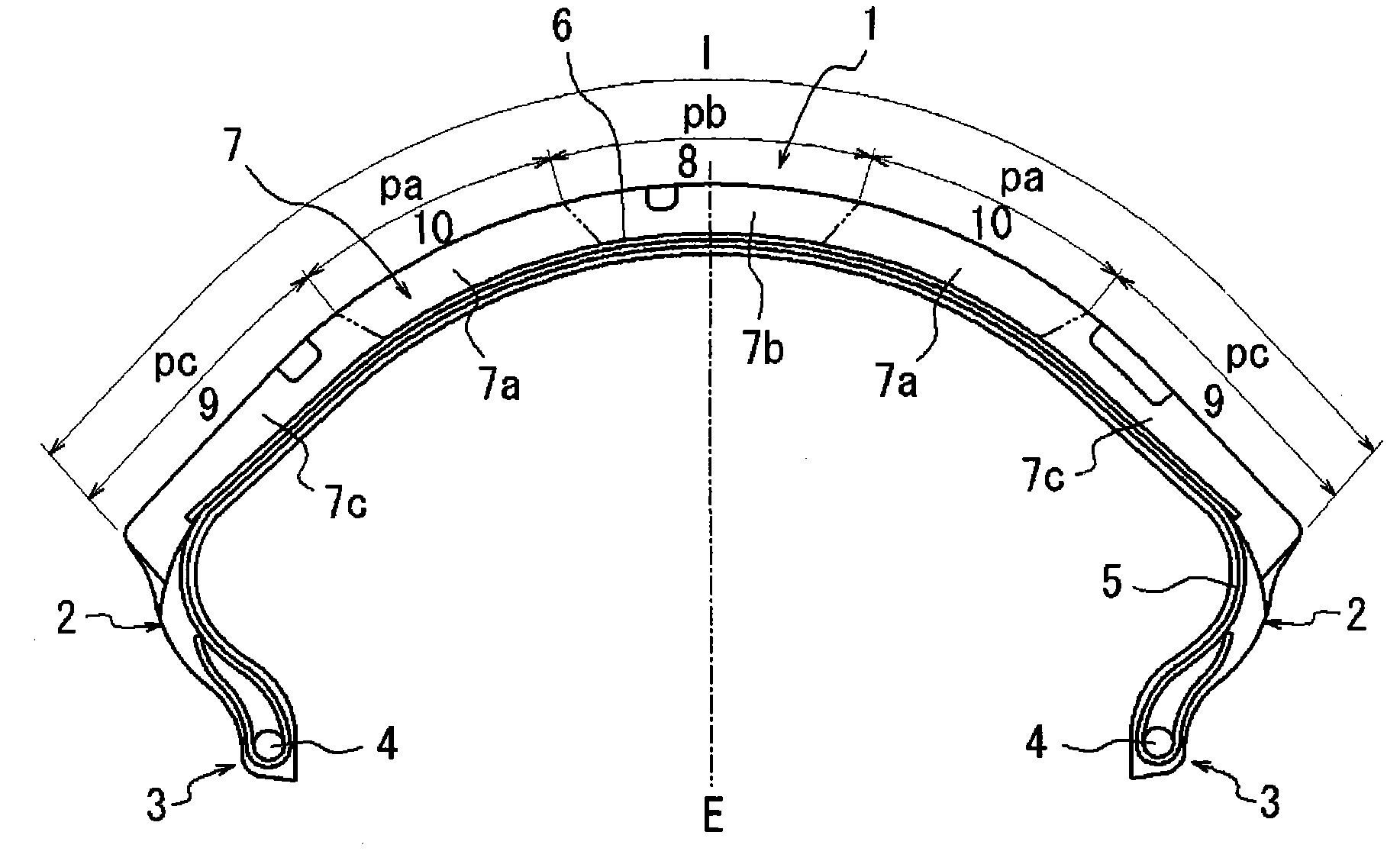

[0078] Example tires, comparative tires and conventional tires for motorcycles were prepared, all of which were 190 / 50ZR17 in size, with a carcass made of two carcass plies made of nylon cords and a steel monofilament spirally wound The parameters of 100% modulus and negative ratio of these test tires are shown in Table 1. Each of these test tires was mounted to the rear wheel of a 1000cc motorcycle having a front tire size of 120 / 70ZR17, and actually ran on the road surface. The road grip of each tire on dry road and wet road was evaluated respectively, and the results shown in Table 2 were obtained.

[0079] The grip on a dry road and the grip on a wet road were evaluated by evaluating the driver's feeling. The results were expressed as index values by using a conventional example tire whose tread rubber was composed of a single type of rubber as a reference.

[0080] A larger index value indicates a better result.

[0081] Table 1

[0082]

[0083]

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com