Bending double-shaft mechanism

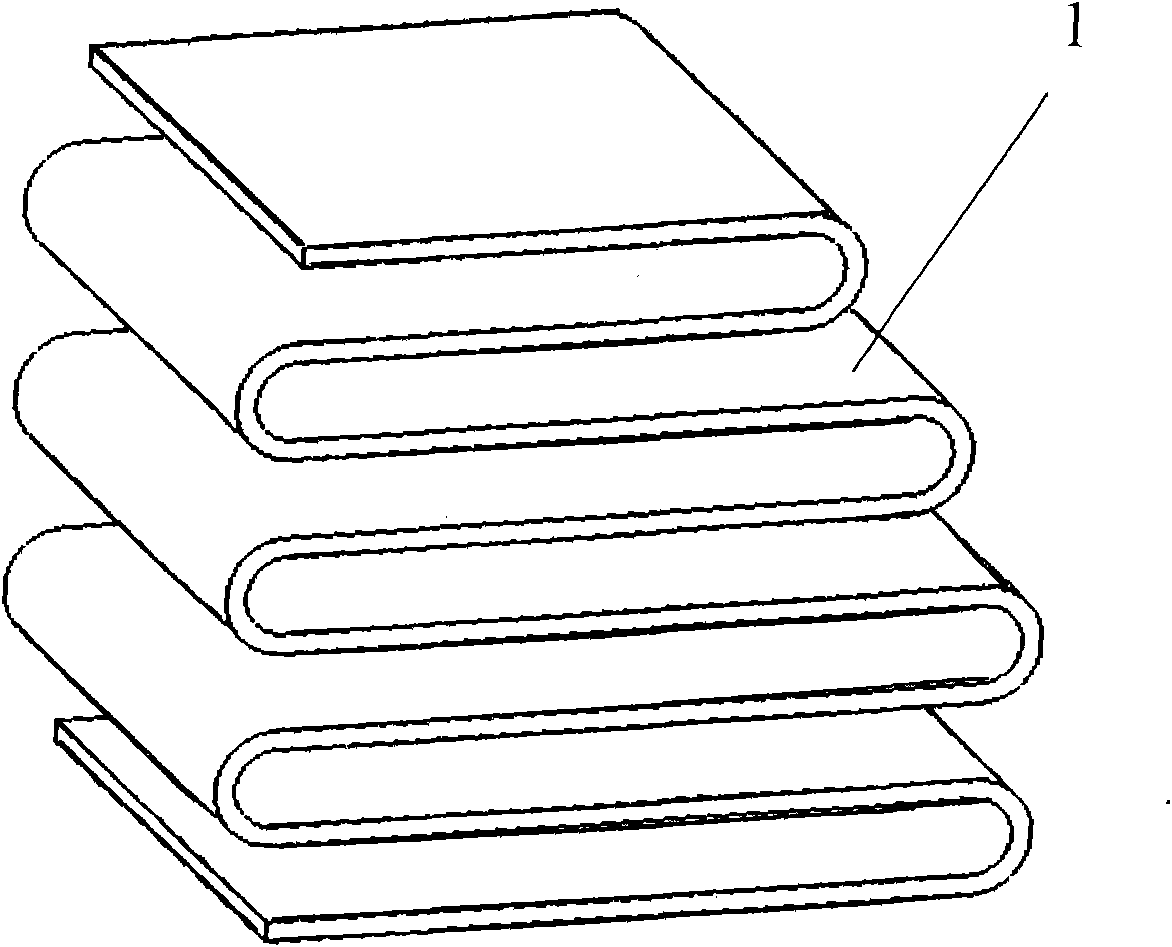

A dual-axis and frame technology, applied in the field of bending dual-axis mechanism, can solve problems such as unfavorable mass production, slow bending speed, broken motor shaft, etc., to prevent axis drift, increase strength, and reduce tube surface. damage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

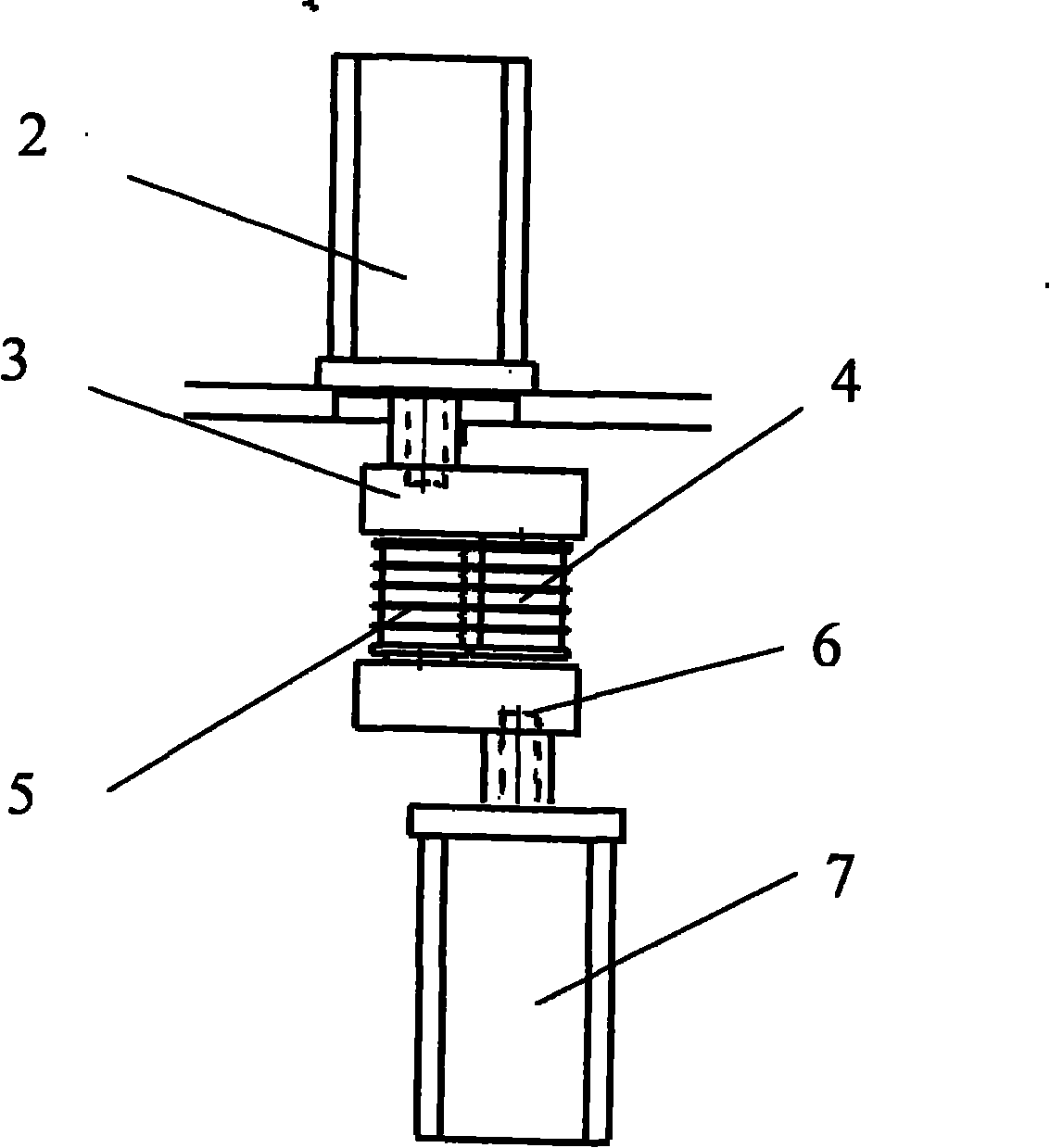

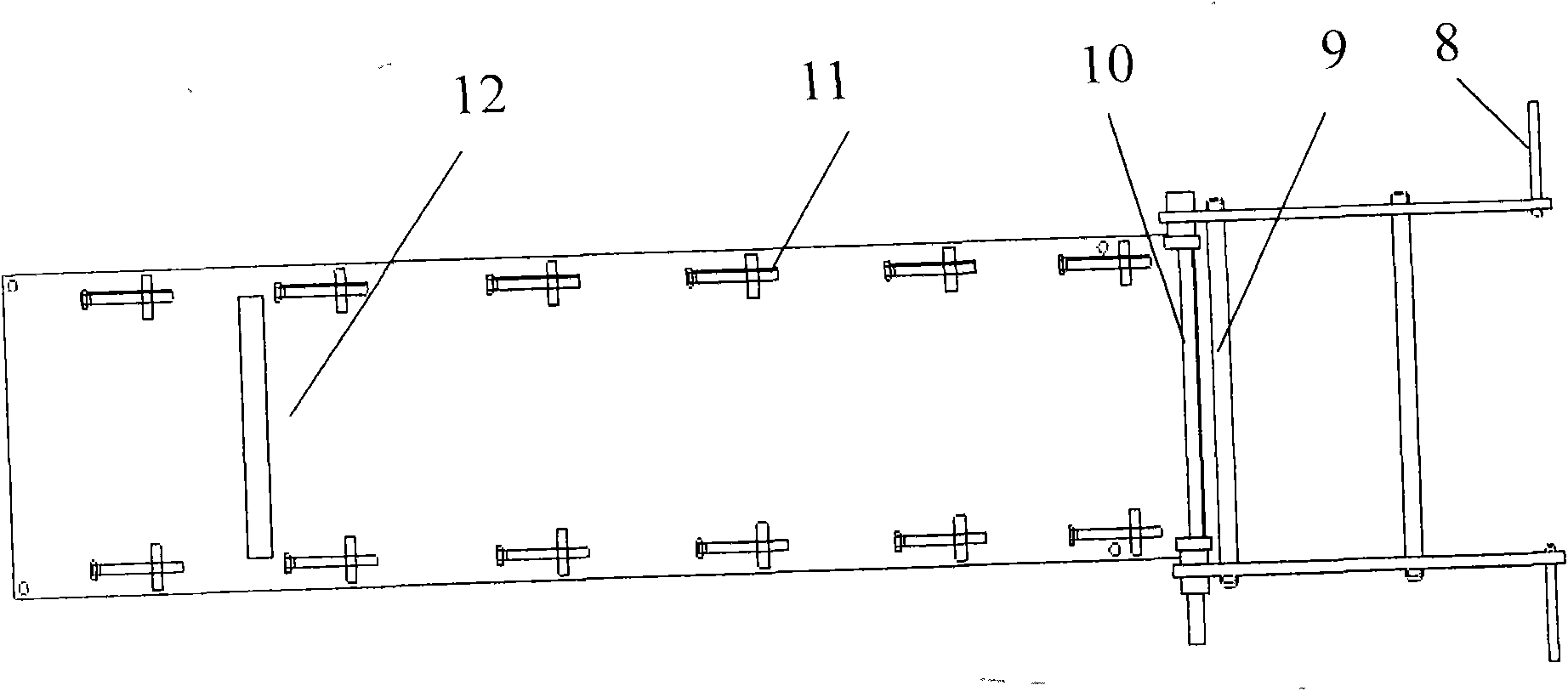

[0007] Embodiments are described in detail with reference to the above drawings. Figure Descriptions 1 to 12 have been described in the background technology and will not be described again. The lower part of the biaxial 18 has a positioning step 18, the distance block 16 is welded on the positioning step of the biaxial, the needle bearing 15 is set on the biaxial 17 and is limited by the positioning step, and the top of the biaxial is equipped with a clamp Block 13 clamps the biaxial by screw 14, (see Figure 4 , 5 ), the shaft member is made up of twist block 20, shaft block 21, motor shaft head 22, (see Figure 6 , 7 , 8) Axle block 21 is placed in the motor shaft head 22, and the motor shaft head is installed in the square groove of twist block 29, and biaxial installation hole 19 is arranged on the twist block, and the lower end of double shaft 17 is put into double shaft after spring 23. Shaft installation hole 19, when the motor shaft head is aligned with the right ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com