Special sand magnetic adsorption method for core-shooting sand core upper die

A magnetic adsorption and sand core technology, applied in magnets, casting molds, mold cores, etc., can solve the problems of joints, gaps, and difficulty in fixing the overall sand core, and achieve the effects of eliminating seams, reducing costs, and facilitating production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Embodiments of the invention. Taking the bolster used in the train carriage as an example, the special sand used in the sand core of the bolster is chromite sand.

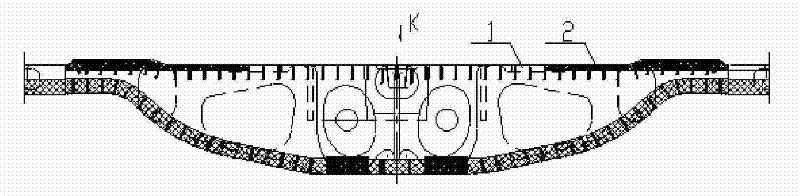

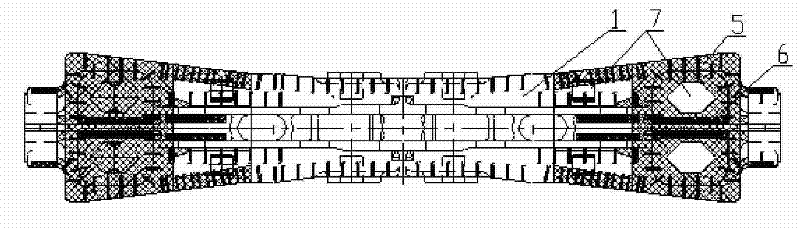

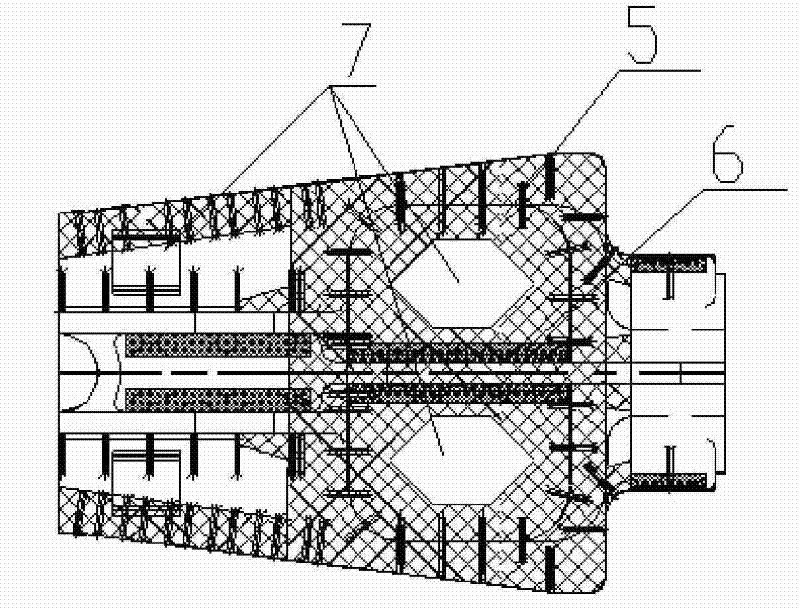

[0020] a. If figure 1 and figure 2 As shown, chromite sand 5 and cold iron 6 need to be placed on the corners of the integral sand core 1 of the bolster. During production, the integral sand core 1 of the bolster needs to be placed on the part where the chromite sand 5 should be placed independently. According to the shape of these parts, local sand cores 2 are made, chromite sand 5 is placed on the local sand cores 2, and steel plates 7 are pre-embedded in the local sand cores 2, such as image 3 shown.

[0021] b. If Figure 4 As shown, the overall core box 3 is made according to the structure of the existing bolster, and the magnet 4 is installed on the inner wall above the overall core box 3. The position of the magnet 4 corresponds to the position of the embedded steel plate 7, and the prepared par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com