Large-caliber optical primary mirror bore finish machining device

A large-diameter, optical technology, applied in metal processing equipment, manufacturing tools, grinding/polishing equipment, etc., can solve the problems of low surface quality, easy taper, difficult dressing of diamond grinding wheel, etc., and achieve low roughness value, roundness The degree value is small, and it is easy to trim the effect of its own outer circle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

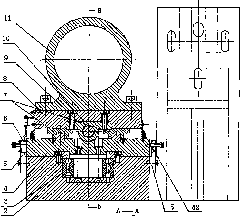

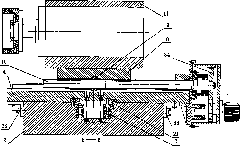

[0029] Such as figure 1 , 2 , 3, the present invention consists of a grinding assembly 1 and an optical main mirror mounting assembly 12. Grinding assembly 1 consists of connecting body 2, rotating assembly 3, guide rail mounting plate 4, linear guide rail pair 7, grinding head assembly mounting plate 8, transmission nut 9, transmission screw rod 10, grinding head lifting mechanism 34, grinding head assembly 11, Guide rail seal 42 , adjustment mechanism 5 and stroke control mechanism 6 . The connecting body 2 and the rotating assembly 3 are pressed on the outer ring of the angular contact bearing 20 through the bearing outer ring pressure ring 21 of the rotating assembly, and fixed on the connecting body 2 with screws. The rotating assembly 3 and the guide rail mounting plate 4 are passed through the rotating assembly 3 The rotating mandrel 19 and the guide rail mounting plate 4 are tightly connected by screws; the guide rail of the linear guide rail pair 7 is fixed on the g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com